The Composition and Benefits of Metal Sandwich Panels

Structure and Materials

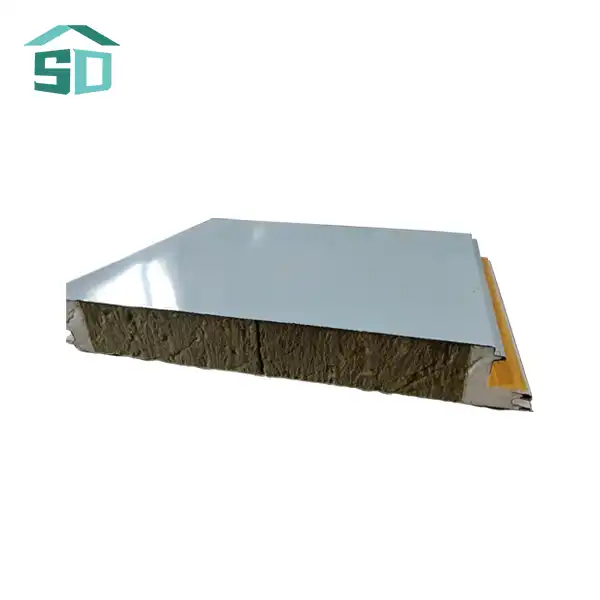

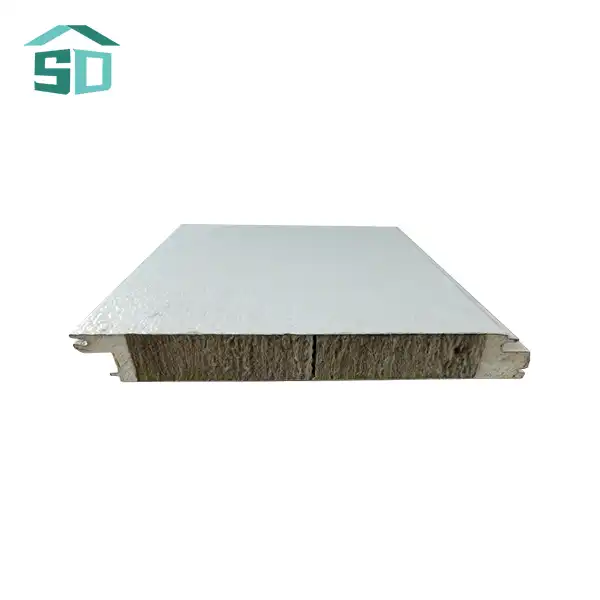

Metal sandwich boards are brilliantly built composite structures. They comprise of two metal facings, ordinarily made from materials such as aluminum, steel, stainless steel, or copper, with a protection center sandwiched between them. This center is as a rule composed of high-performance cover materials like polyurethane, polystyrene, shake fleece, or glass fleece. The thickness of these boards can shift essentially, extending from 30mm to 150mm, permitting for customization based on particular extend necessities.

The external metal layers give solidness and climate resistance, successfully securing buildings from unforgiving natural conditions such as rain, wind, and UV introduction. In the interim, the internal polyurethane center offers uncommon warm and acoustic cover, making a difference keep up comfortable indoor situations and lessening vitality utilization.

This one of a kind combination comes about in a item that is at the same time lightweight and strong, disentangling taking care of and establishment whereas guaranteeing long-lasting execution. As a result, these boards have ended up an great choice for assorted development applications, from mechanical offices to advanced private ventures.

Unparalleled Advantages

The benefits of metal sandwich panels are multifaceted, contributing to their growing popularity in the construction industry:

- Superior Insulation: These panels offer excellent thermal and sound insulation, significantly enhancing energy efficiency and comfort in buildings.

- Durability: Constructed with high-quality materials, metal sandwich panels are resistant to weathering, corrosion, and physical impact, ensuring long-term performance.

- Customizability: They can be tailored in terms of size, color, and thickness to meet specific project requirements, offering great design flexibility.

- Easy Installation: The panels are designed for quick and straightforward installation, which can substantially reduce overall construction time and labor costs.

- Sustainability: Many metal sandwich panels are made with environmentally friendly materials, aligning with green building initiatives and sustainability goals.

Applications and Versatility of Metal Sandwich Panels

Diverse Construction Projects

The versatility of metal sandwich panels is evident in their wide-ranging applications across various construction projects:

- Industrial Buildings: Warehouses, factories, and storage facilities benefit from the panels' durability and insulation properties.

- Commercial Structures: Office buildings, retail spaces, and shopping centers utilize these panels for their aesthetic appeal and energy efficiency.

- Residential Construction: Modern homes and apartment complexes incorporate metal sandwich panels for their sleek appearance and thermal performance.

- Agricultural Buildings: Barns, silos, and greenhouses use these panels for their weather resistance and insulation capabilities.

- Cold Storage Facilities: The superior insulation properties make these panels ideal for maintaining controlled temperatures in cold storage units.

- Sports and Recreational Facilities: Gymnasiums, indoor sports arenas, and community centers benefit from the acoustic properties and durability of these panels.

Exterior and Interior Applications

Metal sandwich panels are not limited to exterior use; they are equally effective in interior applications:

- Exterior Walls: They provide an attractive, weather-resistant facade while offering excellent insulation.

- Roofing Systems: The panels create durable, well-insulated roofs for various building types.

- Interior Partitions: In large open spaces, these panels can be used to create functional, insulated room dividers.

- Ceiling Systems: They offer aesthetic appeal combined with acoustic benefits when used as ceiling panels.

- Doors: Insulated doors for industrial and commercial applications often incorporate metal sandwich panels.

Technical Features and Installation of Metal Sandwich Panels

Advanced Technical Characteristics

Metal sandwich panels boast an array of technical features that contribute to their popularity:

- Fire Resistance: Many panels are designed to meet stringent fire safety standards, making them suitable for high-risk environments.

- Weather Resistance: The panels are often corrosion-resistant and UV-stabilized, ensuring longevity in various climatic conditions.

- Lightweight Design: Despite their strength, these panels are relatively light, facilitating easier handling and installation.

- Low Maintenance: The durable nature of metal sandwich panels means they require minimal upkeep over time.

- Structural Integrity: They can contribute to the overall structural strength of a building, potentially reducing the need for additional support elements.

Installation Process and Considerations

The installation of metal sandwich panels is a streamlined process, but attention to detail is crucial:

1.Surface Preparation: Ensure the installation surface is clean, dry, and free of debris.

2.Measurement and Marking: Accurately measure and mark the areas where panels will be installed.

3.Cutting: If necessary, use appropriate tools to cut panels to desired sizes, following manufacturer guidelines.

4.Mounting: Attach panels to the structure using mechanical fasteners or adhesive, ensuring they are level and properly aligned.

5.Sealing: Apply high-quality sealants to joints for enhanced insulation and moisture protection.

To complement the establishment, different embellishments are accessible, counting sealants for dampness and air-tightness, high-quality latches for secure establishment, and edge trims for a cleaned see and extra climate assurance.

Conclusion

Metal sandwich panels have emerged as a cornerstone in modern construction, offering a unique blend of functionality, aesthetics, and efficiency. Their versatility in application, coupled with superior insulation properties and durability, makes them an invaluable asset in various building projects. As the construction industry continues to evolve, with an increasing focus on energy efficiency and sustainable practices, the role of metal sandwich panels is likely to become even more prominent.

Their ability to meet diverse project requirements while adhering to stringent quality and safety standards positions them as a future-proof solution in the world of construction and architecture. For more information about our range of metal sandwich panels and how they can benefit your next project, please don't hesitate to contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your construction needs.