The Science Behind Eco-Friendly Sandwich Wall Panels

Composition and Structure

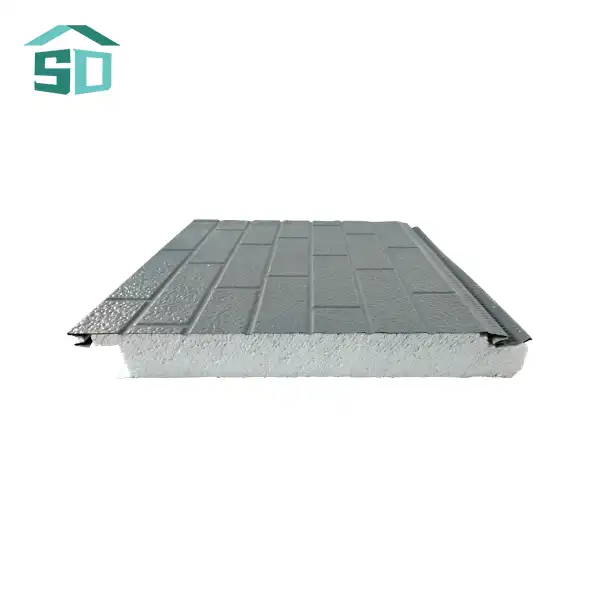

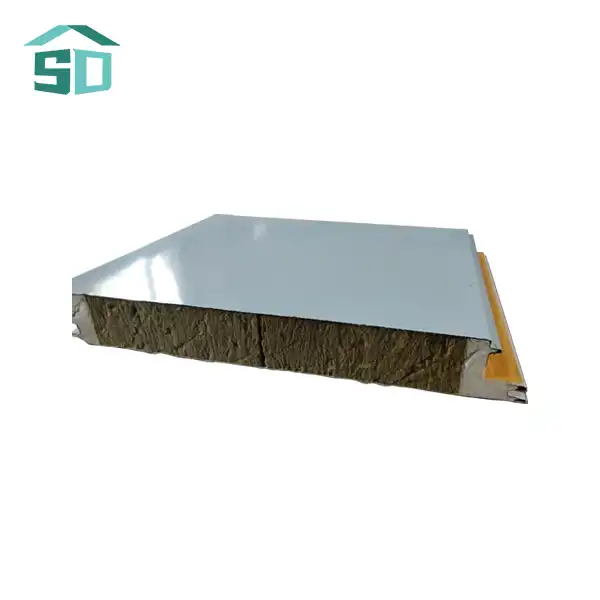

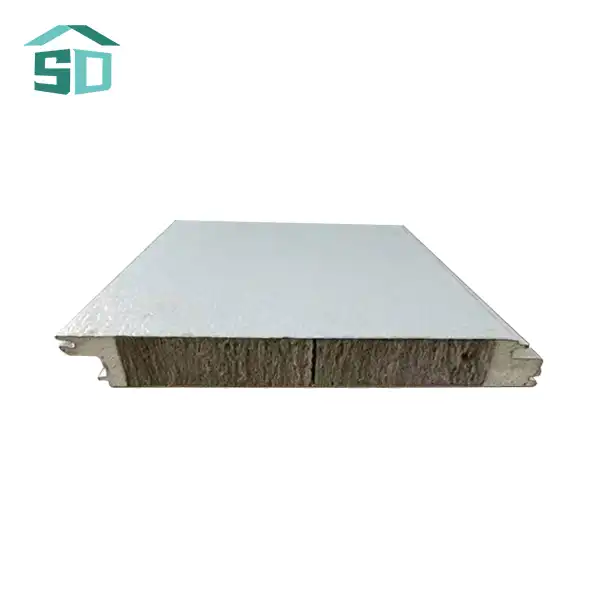

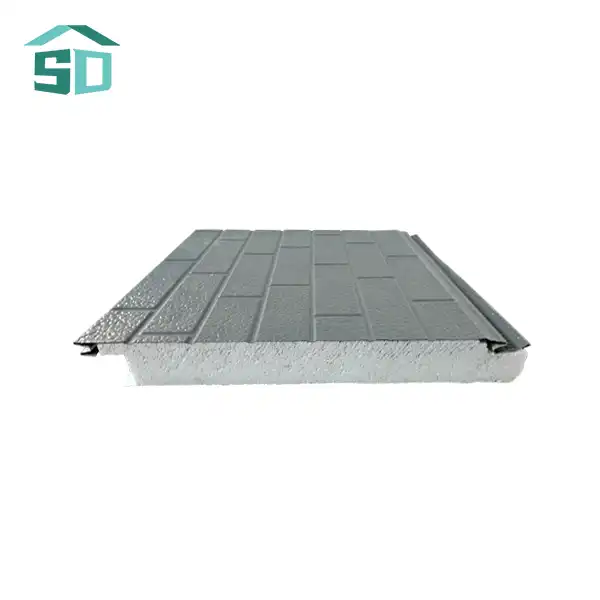

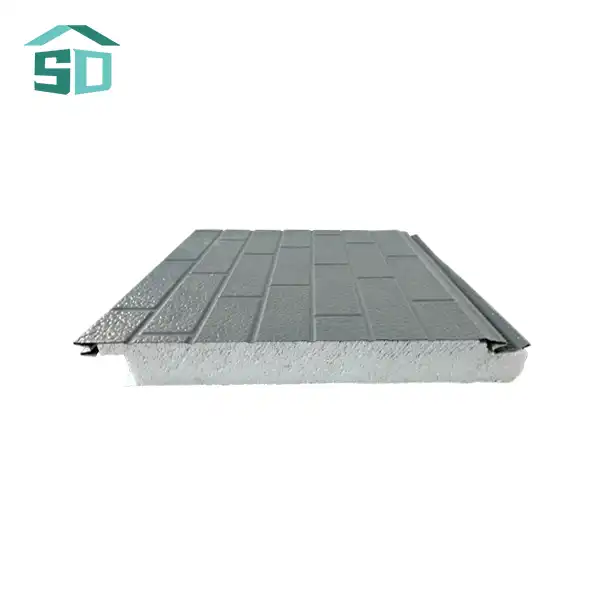

Sandwich panels for walls are marvels of modern engineering, designed to maximize both environmental benefits and structural integrity. At their core, these panels consist of three primary layers: two outer facings and an insulating core. The outer facings are typically made from recycled or recyclable materials such as aluminum, steel, or copper, which provide excellent durability and weather resistance. These materials are not only chosen for their strength but also for their ability to be repurposed at the end of the panel's lifecycle, contributing to a circular economy.

The insulating core, sandwiched between the outer layers, is where much of the eco-friendly innovation takes place. Manufacturers are increasingly utilizing sustainable insulation materials such as recycled polyurethane, bio-based foams, or natural fibers like rock wool or glass wool. These materials offer superior thermal performance while reducing the overall environmental impact of the panel production process.

Strength and Durability

Despite their focus on sustainability, sandwich panels for walls do not compromise on strength. The unique construction method, where the outer facings are bonded to the core material, creates a synergistic effect that enhances the overall structural integrity of the panel. This composite structure distributes loads more effectively than traditional building materials, resulting in a lightweight yet incredibly strong panel.

The strength-to-weight ratio of sandwich panels is particularly impressive, allowing for thinner walls that do not sacrifice load-bearing capacity. This efficiency in material use not only contributes to the eco-friendly nature of the panels but also provides architects and engineers with greater design flexibility.

Environmental Benefits

The environmental advantages of sandwich panels for walls extend beyond their composition. Their superior insulation properties significantly reduce energy consumption in buildings by maintaining consistent indoor temperatures. This thermal efficiency translates to lower heating and cooling costs, as well as a reduced carbon footprint over the building's lifetime.

Moreover, the longevity of these panels means less frequent replacements and renovations, further minimizing waste and resource consumption. Many sandwich panels are also designed for easy disassembly, facilitating recycling or repurposing of materials at the end of their useful life, aligning with circular economy principles.

Innovative Features of Modern Sandwich Wall Panels

Advanced Insulation Technologies

The insulation core of sandwich panels has seen significant advancements in recent years. Cutting-edge materials like aerogels and vacuum insulated panels (VIPs) are being incorporated to achieve unprecedented levels of thermal efficiency. These materials offer superior insulation with minimal thickness, allowing for slimmer wall profiles without sacrificing performance.

Some manufacturers are exploring phase-change materials (PCMs) within the core, which can absorb and release thermal energy as they change state. This technology helps regulate indoor temperatures more effectively, further reducing energy consumption and enhancing comfort.

Smart Integration Capabilities

Modern sandwich panels for walls are not just passive building elements; they're evolving to become active components of smart building systems. Some panels now come with integrated sensors that can monitor temperature, humidity, and even structural integrity. This data can be fed into building management systems to optimize energy usage and preemptively address maintenance needs.

Additionally, there are developments in incorporating photovoltaic cells directly into the outer facing of sandwich panels, turning walls into energy-generating surfaces. This integration of renewable energy production into the building envelope itself represents a significant step towards net-zero energy buildings.

Customization and Aesthetics

Eco-friendly doesn't mean sacrificing visual appeal. Modern sandwich panels for walls offer a wide range of customization options to suit various architectural styles and aesthetic preferences. From different textures and finishes to a diverse color palette achieved through coating, painting, or anodizing, these panels can be tailored to complement any design vision.

Some manufacturers are pushing the boundaries of customization by offering digitally printed facades, allowing for unique patterns, images, or even interactive designs to be applied to the panel surfaces. This level of personalization ensures that sustainable building practices don't come at the cost of creative expression in architecture.

Practical Applications and Future Prospects

Versatility in Construction

The adaptability of sandwich panels for walls makes them suitable for a wide range of construction projects. From residential complexes and office buildings to industrial facilities and educational institutions, these panels offer a versatile solution for both new constructions and renovations. Their lightweight nature makes them particularly valuable in projects where structural load is a concern, such as in the renovation of historic buildings or the construction of additional stories on existing structures.

In the realm of modular and prefabricated construction, sandwich wall panels are proving to be game-changers. Their ease of installation and consistent quality control in manufacturing align perfectly with the principles of off-site construction, enabling faster project completion times and reduced on-site waste.

Advancements in Fire Safety

One of the critical aspects of any building material is its fire safety performance. Modern sandwich panels for walls are designed with this in mind, incorporating fire-resistant materials and constructions that comply with stringent international standards. Some panels utilize mineral wool cores or intumescent coatings that provide enhanced fire protection without compromising on eco-friendliness or structural integrity.

Ongoing research is focused on developing even more advanced fire-retardant materials and designs, aiming to set new benchmarks in building safety while maintaining the panels' environmental credentials.

Future Innovations on the Horizon

The future of sandwich wall panels looks promising, with several exciting developments on the horizon. Researchers are exploring the use of bio-based materials derived from agricultural waste or rapidly renewable resources for both the core and facing materials. These innovations could further reduce the environmental impact of panel production while potentially enhancing their performance characteristics.

Another area of interest is the development of self-healing panels. Inspired by biological systems, these panels would be able to repair minor damages autonomously, extending their lifespan and reducing maintenance needs. This could involve the incorporation of microcapsules containing repair agents or the use of shape-memory materials that can restore their original form after deformation.

As we look to the future, the potential for sandwich panels to contribute to more sustainable and resilient buildings is immense. Their continuous evolution demonstrates the construction industry's commitment to innovation and environmental stewardship.

Conclusion

Eco-friendly sandwich panels for walls represent a significant leap forward in sustainable construction, offering a compelling blend of environmental consciousness and structural prowess. As the building industry continues to grapple with the challenges of climate change and resource scarcity, these innovative panels stand out as a beacon of progress. They not only meet the current demands for energy-efficient and durable building materials but also pave the way for future advancements in construction technology.

For those looking to embrace this cutting-edge technology in their next construction project, Weifang Sandong Building Materials Co., Ltd. stands ready to provide expert guidance and top-quality products. Our commitment to innovation and sustainability ensures that you'll have access to the latest in eco-friendly sandwich panel technology. To learn more about how these panels can benefit your project, or to discuss custom solutions tailored to your specific needs, don't hesitate to reach out to us at info@sdqsc.com. Together, we can build a more sustainable future, one panel at a time.