Exploring the Versatility of External Wall Cladding Materials

Metal Cladding: Durability Meets Design

Metal cladding stands out as a premier choice for external wall applications, offering an unparalleled blend of durability and aesthetic appeal. Aluminum, steel, stainless steel, and copper are the frontrunners in this category, each bringing unique attributes to the table.

Aluminum cladding is prized for its lightweight nature and erosion resistance. Its flexibility permits for complicated plans, making it a favorite among modelers looking for to make outwardly striking veneers. Steel, on the other hand, offers remarkable quality and fire resistance, making it perfect for high-rise buildings and structures in challenging situations.

Stainless steel cladding elevates the durability factor, providing superior resistance to rust and staining. Its sleek, modern appearance makes it a popular choice for contemporary architectural designs. Copper cladding, while less common, offers a unique aesthetic as it naturally patinas over time, transforming from a bright penny hue to a distinctive green verdigris.

These metal cladding options not only protect buildings from the elements but also contribute to their longevity. With proper installation and maintenance, metal cladding can last for decades, making it a cost-effective solution in the long run.

Insulated Cladding: Marrying Aesthetics with Energy Efficiency

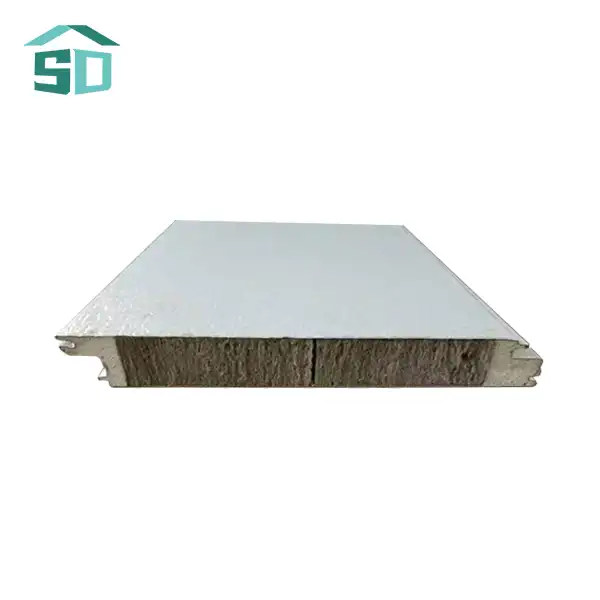

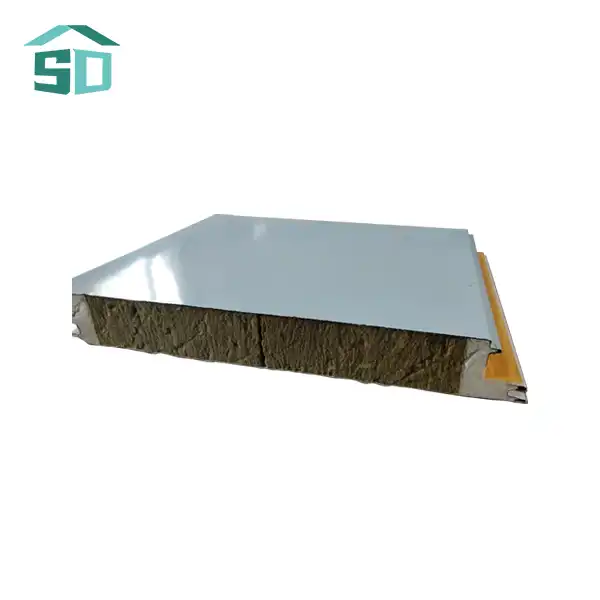

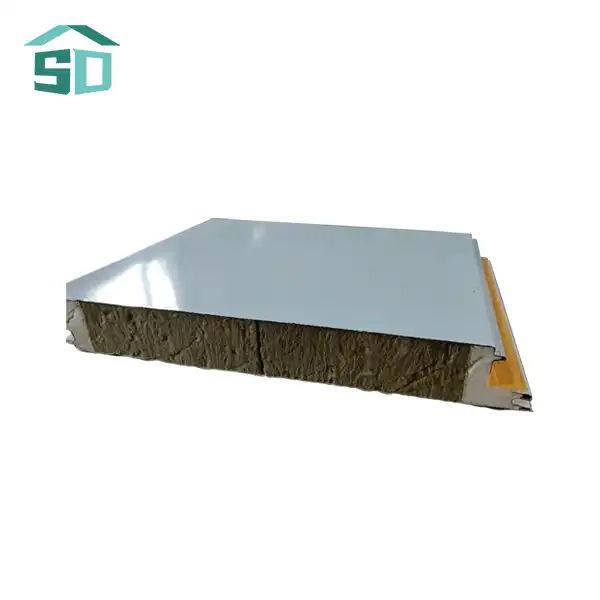

As energy efficiency becomes increasingly crucial in modern construction, insulated external wall cladding has emerged as a game-changer. These systems combine the protective and aesthetic qualities of traditional cladding with high-performance insulation materials.

Polyurethane and polystyrene are well known choices for separator in cladding boards due to their great warm properties and lightweight nature. Shake fleece and glass fleece offer predominant fire resistance and sound cover, making them perfect for buildings in urban situations or zones with strict fire security directions.

Insulated cladding systems significantly enhance a building's thermal envelope, reducing heat loss in winter and heat gain in summer. This translates to lower energy consumption for heating and cooling, resulting in reduced operational costs and a smaller carbon footprint.

Moreover, these systems address the issue of thermal bridging, a common problem in traditional construction methods. By providing a continuous layer of insulation, they eliminate cold spots and improve overall thermal performance.

Technical Features and Performance of External Wall Cladding

Weather Resistance and Longevity

One of the primary functions of external wall cladding is to protect the building structure from environmental elements. High-quality cladding systems are engineered to resist UV rays, moisture, and corrosion, ensuring the longevity and reliability of the building envelope.

Progressed coating advances advance improve the climate resistance of metal cladding. For occasion, fluoropolymer coatings give uncommon resistance to blurring, chalking, and chemical debasement, keeping up the cladding's appearance and execution over time.

The thickness of cladding panels, ranging from 20mm to 150mm, plays a crucial role in their performance. Thicker panels generally offer improved insulation and structural integrity, while thinner options may be preferred for lightweight applications or renovations.

Fire Performance and Safety Considerations

Fire safety is paramount in building design, and external wall cladding plays a critical role in this aspect. High-quality cladding systems comply with stringent fire safety regulations, offering peace of mind to building owners and occupants.

Many cladding materials, particularly those used in high-rise buildings, are designed to be non-combustible or have a Class A fire rating. This classification indicates the highest level of fire resistance, ensuring that the cladding does not contribute to the spread of flames in the event of a fire.

It's worth noting that fire performance is not solely dependent on the cladding material itself. The entire cladding system, including insulation and installation methods, must be considered to ensure comprehensive fire safety.

Customization and Aesthetic Versatility

External wall cladding offers unparalleled opportunities for customization, allowing architects and designers to bring their creative visions to life. The wide range of colors, textures, and surface finishes available enables the creation of truly unique building facades.

Metal cladding, in specific, loans itself well to different wraps up, from smooth, cleaned surfaces to finished, matte appearances. The capacity to blend and coordinate distinctive colors and wraps up inside the same cladding framework permits for complicated designs and plans that can change a building's appearance.

Furthermore, the flexibility in panel sizes and shapes enables the creation of complex geometries and three-dimensional facades. This versatility makes external wall cladding an invaluable tool in modern architectural design, capable of adapting to diverse styles from minimalist contemporary to bold, avant-garde expressions.

Installation and Maintenance of External Wall Cladding

Professional Installation for Optimal Performance

The effectiveness of external wall cladding largely depends on proper installation. Professional installation ensures that the cladding system performs as intended, providing maximum protection and efficiency. The installation process typically begins with thorough surface preparation, ensuring that the underlying wall is clean, dry, and structurally sound. A suitable mounting framework is then installed, providing a solid base for attaching the cladding panels.

Exactness is key amid board connection, as legitimate arrangement and secure fitting are vital for both aesthetics and execution. Specialized clasp and clips planned for particular cladding frameworks are utilized to guarantee solidness and resistance to wind loads. Sealant application at joints and seams is a critical step in preventing moisture ingress. High-quality, weather-resistant sealants are used to create a watertight barrier, protecting the building structure from potential water damage.

Maintenance and Long-Term Care

While external wall cladding is designed for durability and longevity, regular maintenance can further extend its lifespan and preserve its appearance. Maintenance requirements vary depending on the cladding material and environmental conditions. For metal cladding, periodic cleaning with mild detergent and water is usually sufficient to maintain its appearance. Regular inspections should be conducted to check for any signs of damage, loose panels, or deteriorating sealants.

Protects cladding frameworks may require extra consideration to guarantee the judgment of the separator layer. Any harm to the external cladding ought to be expeditiously tended to to avoid dampness from compromising the separator. It's advisable to follow manufacturer-specific maintenance guidelines and schedule professional inspections at regular intervals. This proactive approach can identify and address potential issues before they escalate, ensuring the cladding continues to perform optimally throughout its lifespan.

Conclusion

External wall cladding represents a fusion of form and function in modern architecture. The diverse range of materials available, from durable metals to innovative insulated panels, offers solutions for virtually any building project. By carefully considering factors such as climate, design requirements, and performance expectations, architects and builders can select the ideal cladding solution to enhance both the aesthetics and functionality of their structures.

As the construction industry continues to evolve, external wall cladding remains at the forefront of building envelope technology. Its ability to combine durability, energy efficiency, and design flexibility makes it an indispensable element in creating sustainable, beautiful, and long-lasting buildings. For more information on external wall cladding solutions and how they can benefit your project, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect cladding system for your unique needs.