Preparation: Setting the Stage for Successful Installation

Assessing Your Space and Gathering Materials

Before diving into the installation process, it's essential to thoroughly assess your space and gather all necessary materials. Start by measuring the area where you plan to install the thermal insulation panels. This will help you determine the quantity of panels needed and identify any potential challenges or obstacles in the installation area.

Next, compile a list of tools and materials required for the job. Some essential items include:

- Thermal insulation panels

- Measuring tape

- Utility knife or panel cutter

- Adhesive or mechanical fasteners

- Sealant

- Safety equipment (gloves, goggles, dust mask)

- Straight edge or level

- Marker or pencil

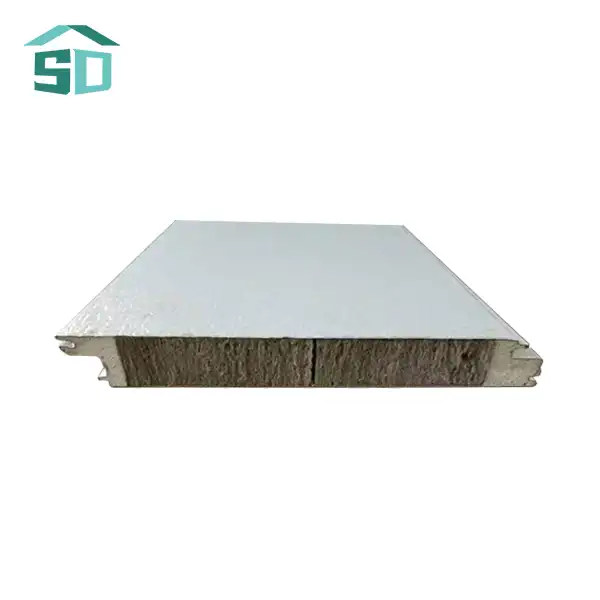

Ensure you have high-quality thermal insulation panels that meet your specific needs. Our panels at Weifang Sandong Building Materials Co., Ltd. offer superior insulation properties with a thermal conductivity of 0.018W/m.k and a thermal resistance of 2.09m2k/w. These panels are designed to provide an effective barrier against heat and cold, ensuring year-round comfort in your space.

Surface Preparation

Appropriate surface arrangement is significant for guaranteeing the life span and viability of your warm separator boards. Start by completely cleaning the establishment surface, expelling any clean, flotsam and jetsam, or free materials. If there are any existing splits or harms, repair them some time recently continuing with the establishment.

For optimal adhesion, ensure the surface is completely dry. If you're working in an area prone to moisture, consider applying a waterproof membrane or barrier before installing the panels. Our thermal insulation panels boast a waterproof rate of 0.0008, providing excellent protection against moisture intrusion.

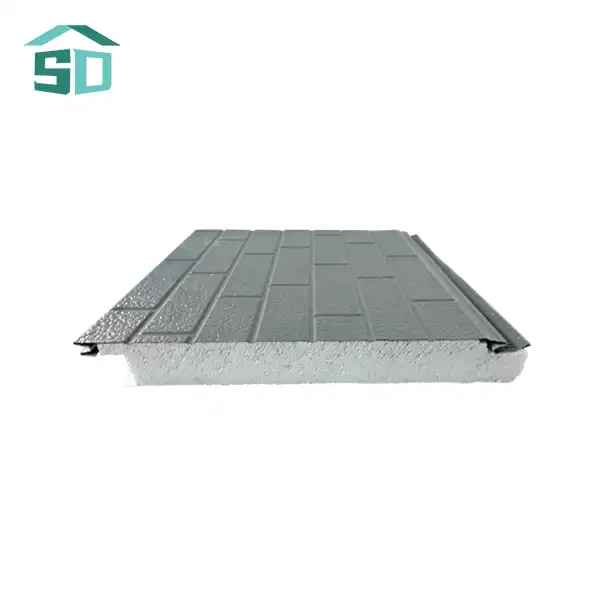

If you're introducing the boards on an outside surface, take note of the wind resistance prerequisites in your region. Our boards are planned to withstand wind weights up to 8.0 Kpa, making them appropriate for different natural conditions.

Installation Process: Precision and Care

Layout Planning

Before cutting or attaching any panels, it's crucial to plan your layout carefully. This step will help minimize waste and ensure a visually appealing result. Start by marking reference lines on the installation surface using a level or straight edge. These lines will guide you in placing the panels evenly and maintaining proper alignment throughout the installation process.

Consider the dimensions of our thermal insulation panels when planning your layout. For exterior applications, panels are available in widths of 383mm, while interior panels come in 450mm widths. The thickness can vary from 10mm for interior applications to 16mm or 20mm for exterior use.

Cutting and Fitting

With your layout planned, you can now begin cutting the thermal insulation panels to fit your space. Use a sharp utility knife or a specialized panel cutter to achieve clean, precise cuts. Always measure twice and cut once to avoid errors and material waste. When cutting, pay consideration to any ranges that require extraordinary fitting, such as around windows, entryways, or electrical outlets.

Our boards, with their customizable lengths, permit for adaptability in fitting different spaces and building highlights. Remember to wear appropriate safety gear, including gloves and safety glasses, when cutting the panels. The thickness of the surface materials (0.23mm, 0.25mm, or 0.27mm) may require different cutting techniques, so adjust your approach accordingly.

Attachment and Sealing

Once your boards are cut to estimate, it's time to join them to the arranged surface. Depending on your particular application and neighborhood building codes, you may utilize either cement or mechanical clasp. For cement application, guarantee indeed scope and take after the manufacturer's informational with respect to drying times and natural conditions. If using mechanical fasteners, space them according to the panel manufacturer's recommendations and local building codes. This is particularly important for exterior applications where wind resistance is a factor.

After attaching the panels, pay special attention to the seams and edges. Apply a high-quality sealant to these areas to prevent moisture ingress and air leakage. This step is crucial for maintaining the panels' insulation effectiveness and longevity. Our thermal insulation panels have a compressive strength of 52.7kpa, allowing them to withstand the pressure of proper attachment without compromising their insulative properties.

Finishing Touches: Ensuring Optimal Performance

Inspection and Quality Control

After installation, conduct a thorough inspection of your work. Check for any gaps, misalignments, or areas where the sealant may not have been applied correctly. Pay close attention to corners, edges, and areas around fixtures or penetrations. Verify that all panels are securely attached and that there are no visible signs of damage or stress. This inspection is crucial for ensuring the longevity and effectiveness of your thermal insulation system.

Additional Considerations for Specific Applications

Depending on your particular application, there may be extra steps or contemplations to keep in intellect. For outside establishments, guarantee that the boards are legitimately coordinates with your building's water administration framework to avoid dampness issues. In areas where fire safety is a particular concern, note that our thermal insulation panels come with a fire-protection rating of B1/B2, providing an added layer of safety to your structure.

For interior applications, consider how the panels will interact with your chosen wall coverings or finishes. Our panels can be customized in various colors and patterns to suit your décor preferences while maintaining their superior insulative properties.

Maintenance and Long-Term Care

To maximize the lifespan and performance of your thermal insulation panels, implement a regular maintenance routine. This may include periodic inspections for any signs of damage or wear, cleaning the panels according to manufacturer recommendations, and promptly addressing any issues that arise.

Conclusion

Our thermal insulation panels are designed for durability and longevity, with a corrosion-free design that resists environmental degradation. However, proper maintenance will ensure they continue to provide optimal insulation and energy efficiency for years to come. By following this comprehensive guide, you can confidently install thermal insulation panels and enjoy the benefits of improved energy efficiency, comfort, and sustainability in your building.

Remember that while DIY installation is possible, consulting with professionals can ensure the best results, especially for large-scale or complex projects. For more information about our high-quality thermal insulation panels and other exterior cladding and facade solutions, please don't hesitate to contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is committed to providing you with the finest products and unparalleled service to enhance your building projects.