Understanding Polyurethane Insulation Panels: Composition and Properties

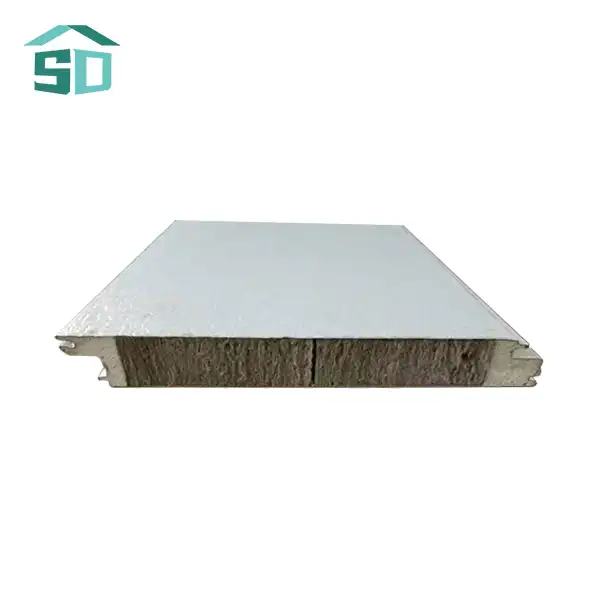

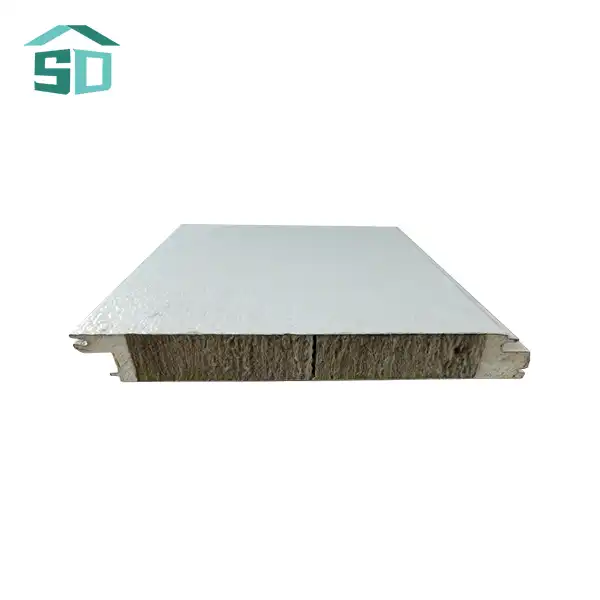

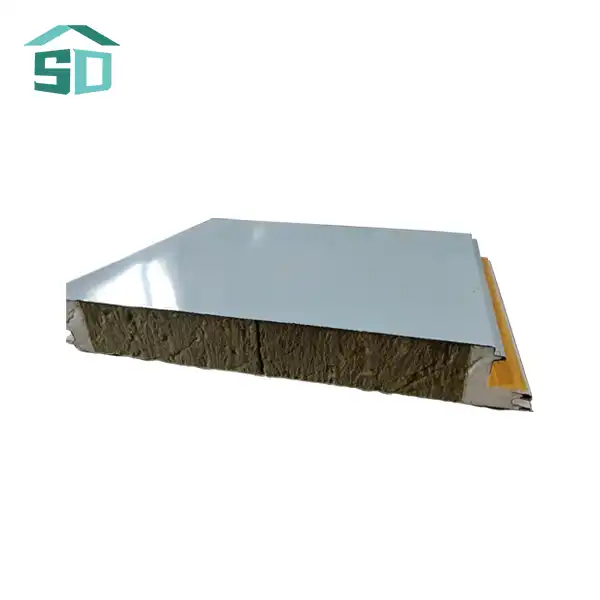

Polyurethane separator boards are progressed building materials that offer prevalent warm execution and flexibility. These boards are composed of an inflexible polyurethane froth center sandwiched between two layers of high-quality confronting materials. The special properties of polyurethane froth make these boards a fabulous choice for different separator applications.

Composition of Polyurethane Insulation Panels

The core of polyurethane insulation panels is made from a specialized foam that is created through a chemical reaction between polyol and isocyanate. This response produces a closed-cell structure that traps minor discuss bubbles, coming about in uncommon protection properties. The froth center is at that point fortified to confronting materials, which can incorporate metal, aluminum thwart, or other solid surfaces, depending on the particular application prerequisites.

Key Properties of Polyurethane Insulation Panels

Polyurethane separator boards gloat a few noteworthy properties that make them a well known choice in the development industry:

- Thermal Conductivity: With a thermal conductivity of 0.022 W/mK, these panels offer excellent insulation, helping to maintain comfortable indoor temperatures year-round.

- Density and Weight: Polyurethane panels are lightweight, typically weighing between 8-12 kg/m², making them easy to handle and install.

- Moisture Resistance: The closed-cell structure of polyurethane foam provides excellent moisture resistance, preventing water absorption and reducing the risk of mold growth.

- Durability: These panels are known for their long-lasting performance, maintaining their insulating properties over time.

- Versatility: Available in various thicknesses (50mm, 75mm, 100mm, and custom options) and sizes (standard 1200 x 2400 mm or custom), polyurethane panels can be tailored to meet specific project requirements.

Safety Features and Compliance of Polyurethane Insulation Panels

When it comes to building materials, security is vital. Polyurethane cover boards have been planned and made with security in intellect, following to strict industry measures and controls.

Fire Safety and Resistance

One of the basic security concerns with any cover texture is its fire resistance. Polyurethane cover sheets address this concern by fulfilling a Lesson B2 fire rating, classifying them as non-combustible. This rating guarantees that the boards meet vital fire security measures for development ventures. Amid a fire occasion, these boards are planned to restrain fire spread and smoke improvement, giving profitable time for tenants to empty securely.

Environmental and Health Considerations

Polyurethane insulation panels are engineered to have a low environmental impact. They are made from ecologically neighborly materials and contribute to vitality proficiency objectives by lessening the in general vitality utilization of buildings. This not as it were makes a difference in lessening carbon impressions but moreover adjusts with economical building hones.

From a health perspective, these panels are designed to be inert and non-toxic during normal use. Their moisture-resistant properties help prevent the growth of mold and mildew, contributing to a healthier indoor environment. This is particularly beneficial for individuals with respiratory sensitivities or allergies.

Regulatory Compliance and Quality Control

Makers of polyurethane cover sheets, such as Weifang Sandong Building Materials Co., Ltd., take after to strict quality control measures. These consolidate comprehensive appraisals of rough materials like steel coils, aluminum obstruct, and polyurethane. The era handle incorporates careful testing of thing thickness, paint film thickness, mechanical quality, fire retardancy, and in common thing appearance.

By complying with industry standards and regulations, these panels ensure not only safety but also reliability and performance consistency. This commitment to quality and safety makes polyurethane insulation panels a trustworthy choice for various construction applications.

Applications and Benefits of Polyurethane Insulation Panels

Polyurethane insulation panels offer a wide range of applications across various sectors of the construction industry. Their versatility and superior performance make them an attractive option for both new constructions and renovation projects.

Versatile Applications in Construction

These panels find use in numerous construction projects, including:

- Residential complexes and individual homes

- Office buildings and commercial spaces

- Industrial facilities and warehouses

- Agricultural structures

- Cold storage facilities

- Historic building renovations

- Municipal buildings and security kiosks

The adaptability of polyurethane insulation panels allows them to be used in walls, roofs, and ceilings, providing comprehensive insulation solutions for entire structures.

Key Benefits of Using Polyurethane Insulation Panels

The use of polyurethane insulation panels offers numerous advantages:

- Superior Insulation: With their high R-value, these panels provide excellent thermal insulation, significantly reducing energy consumption for heating and cooling.

- Energy Efficiency: By maintaining consistent indoor temperatures, polyurethane panels contribute to lower energy bills and reduced carbon emissions.

- Moisture Control: Their moisture-resistant properties help prevent water damage and mold growth, ensuring a healthier living or working environment.

- Sound Insulation: These panels also offer sound dampening properties, making them ideal for noise-sensitive applications.

- Easy Installation: The lightweight nature of polyurethane panels, combined with their easy-to-handle sizes, reduces installation time and labor costs.

- Durability: Polyurethane insulation panels maintain their performance over time, offering a long-lasting solution that requires minimal maintenance.

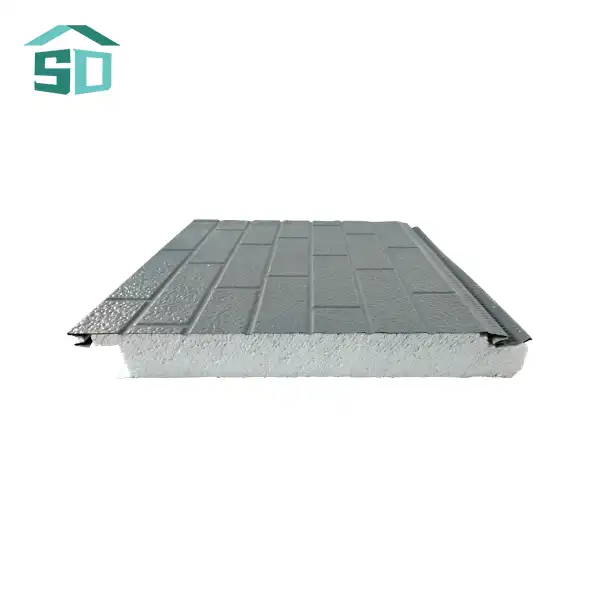

- Aesthetic Flexibility: Available in various colors and surface treatments (smooth, textured, or coated), these panels can be customized to meet specific aesthetic requirements.

Cost-Effectiveness and Long-Term Value

While the initial cost of polyurethane insulation panels may be higher than some traditional insulation materials, their long-term value proposition is compelling. The energy savings accrued over time, combined with their durability and low maintenance requirements, often result in a favorable return on investment. Additionally, their contribution to creating more comfortable and healthier indoor environments adds intangible value to both residential and commercial properties.

Conclusion

Polyurethane insulation panels offer a safe, efficient, and versatile solution for modern construction needs. Their combination of superior insulation properties, fire resistance, and environmental benefits make them an excellent choice for a wide range of applications. As the construction industry continues to prioritize energy efficiency and sustainability, these panels are likely to play an increasingly important role in building design and renovation.

For more information about polyurethane insulation panels and other exterior cladding and facade solutions, please contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your next project.