Understanding Insulated Sandwich Wall Panels: A Comprehensive Guide

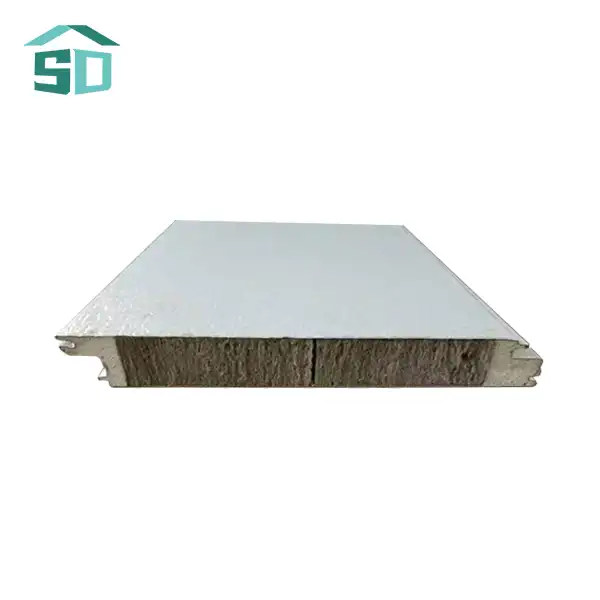

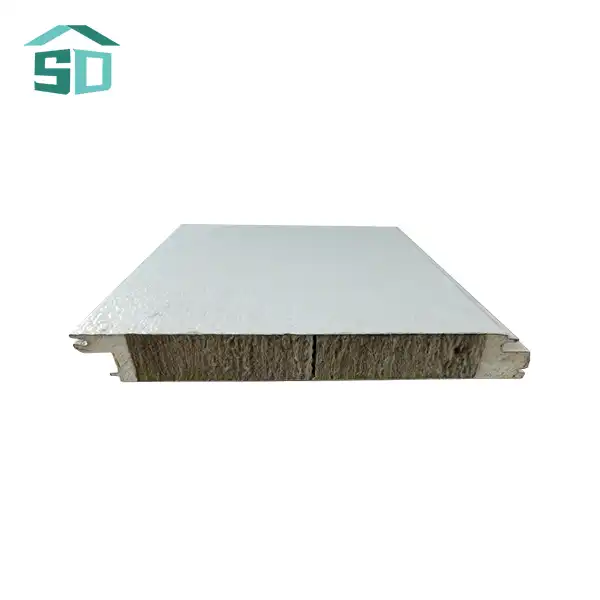

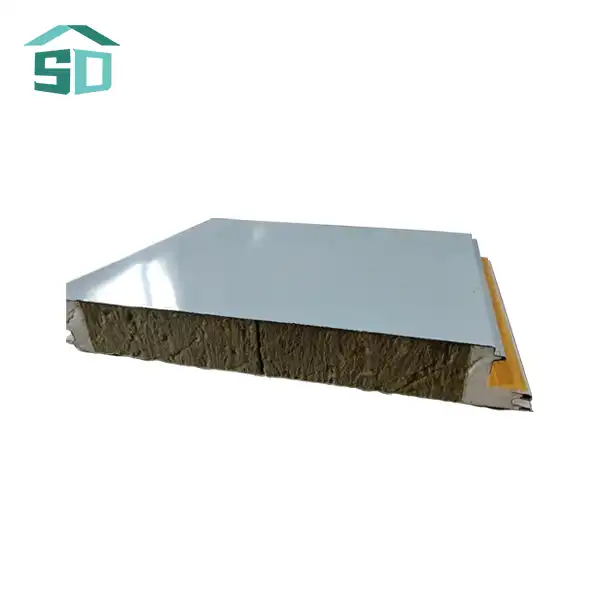

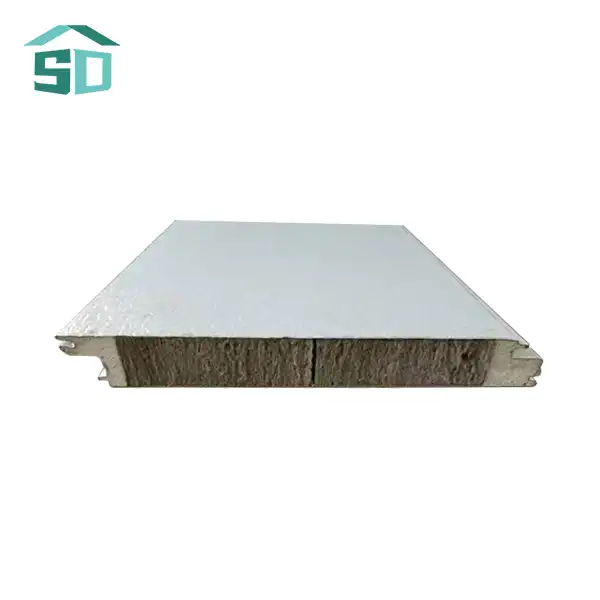

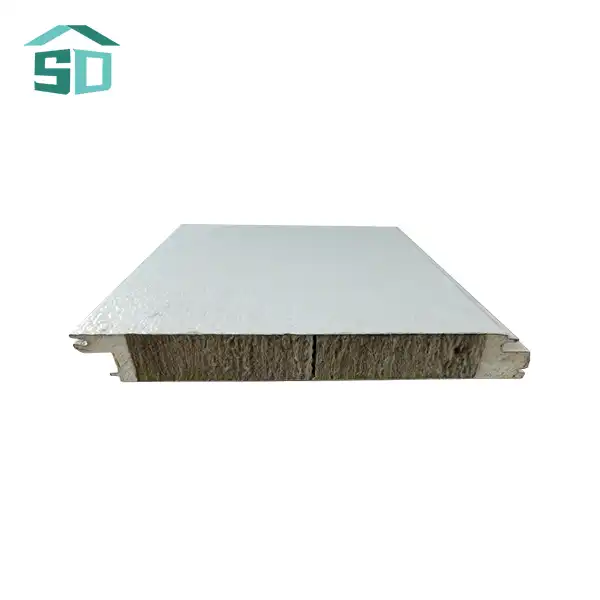

Insulated sandwich wall panels are innovative building materials that have revolutionized modern construction. These versatile panels consist of two metal facings with an insulating core sandwiched between them. The result is a robust, energy-efficient solution that offers superior thermal performance and structural integrity.

Composition and Structure

The typical insulated sandwich wall panel comprises three main components:

- Exterior facing: Usually made of steel or aluminum, with thicknesses ranging from 0.23mm to 0.27mm.

- Insulating core: Often composed of polyurethane foam, providing excellent thermal insulation.

- Interior facing: Similar to the exterior, but may have different thickness or finish options.

These panels come in various dimensions to suit different project requirements. For example, exterior panels may have a width of 383mm, while interior panels could be 450mm wide. The overall thickness can vary, with interior panels typically around 10mm and exterior panels ranging from 16mm to 20mm.

Key Performance Characteristics

Insulated sandwich wall panels boast impressive performance metrics that make them ideal for diverse applications:

- Fire protection: Rated B1/B2, ensuring safety in the event of a fire.

- Waterproofing: With a rate of 0.0008, these panels offer excellent moisture resistance.

- Wind resistance: Capable of withstanding pressures up to 8.0 kPa.

- Thermal efficiency: Featuring a thermal conductivity of 0.018 W/m.K and thermal resistance of 2.09 m²K/W.

- Strength: Demonstrating a compressive strength of 52.7 kPa.

Applications and Benefits

The versatility of insulated sandwich wall panels makes them suitable for a wide range of construction projects, including:

- Residential complexes

- Office buildings

- Industrial facilities

- Agricultural structures

- Cold storage units

These panels offer numerous benefits, such as rapid installation, superior insulation, and customizable aesthetics. They contribute to energy-efficient building envelopes, reducing heating and cooling costs while providing a durable, low-maintenance exterior solution.

Step-by-Step Installation Process for Insulated Sandwich Wall Panels

Installing insulated sandwich wall panels requires attention to detail and adherence to best practices. Follow this comprehensive guide to ensure a professional installation:

Pre-Installation Preparations

Before beginning the installation process, take these crucial steps:

- Inspect the panels for any damage or defects upon delivery.

- Store panels in a dry, covered area to protect them from moisture and direct sunlight.

- Review the manufacturer's installation guidelines and local building codes.

- Gather all necessary tools and equipment, including fasteners, sealants, and safety gear.

Surface Preparation

Proper surface preparation is essential for a successful installation:

- Clean the installation surface thoroughly, removing any dirt, debris, or old materials.

- Ensure the surface is dry and free from any moisture that could compromise the panel's performance.

- Check for levelness and make any necessary adjustments to create a flat, even surface.

- Apply a vapor barrier if required by local building codes or project specifications.

Panel Layout and Cutting

Careful planning of the panel layout is crucial:

- Measure the installation area and create a detailed layout plan.

- Account for openings such as windows, doors, and ventilation systems.

- Use appropriate cutting tools to trim panels as needed, following manufacturer guidelines for edge treatment.

- Ensure proper overlapping at panel joints to maintain water tightness.

Panel Installation

Follow these steps for a secure and efficient panel installation:

- Begin installation at a corner or edge of the building, working your way across and up.

- Use recommended fasteners to secure panels, ensuring proper spacing and depth.

- Install flashing and trim pieces at openings and edges to prevent water infiltration.

- Pay special attention to panel joints, ensuring proper alignment and sealing.

Sealing and Finishing

Complete the installation with these final steps:

- Apply high-quality sealants to all joints, penetrations, and flashings.

- Install any additional trim or decorative elements as specified in the design.

- Conduct a final inspection to ensure all panels are securely fastened and properly sealed.

- Clean the installed panels according to manufacturer recommendations.

Maximizing Performance and Longevity of Insulated Sandwich Wall Panels

To ensure your insulated sandwich wall panels provide optimal performance and durability for years to come, consider the following best practices:

Regular Maintenance and Inspections

Implement a proactive maintenance schedule:

- Conduct visual inspections at least twice a year, looking for signs of damage or wear.

- Check for any loose fasteners or sealant failures and address them promptly.

- Clean panels regularly using mild detergents and soft brushes to prevent dirt buildup.

- Remove any vegetation or debris that may accumulate near the panels.

Addressing Potential Issues

Be prepared to address common issues that may arise:

- Moisture infiltration: Identify and seal any gaps or breaches in the panel system.

- Thermal bridging: Ensure proper insulation at panel joints and penetrations.

- Surface damage: Repair any scratches or dents according to manufacturer guidelines.

- Fading or discoloration: Consider repainting or refinishing panels if necessary.

Enhancing Energy Efficiency

Maximize the energy-saving potential of your insulated sandwich wall panels:

- Integrate panels with other energy-efficient building systems, such as high-performance windows and doors.

- Consider adding additional insulation in critical areas to further reduce heat transfer.

- Use thermal imaging to identify any weak points in the building envelope and address them accordingly.

- Implement smart building technologies to optimize heating and cooling systems in conjunction with the panel's insulation properties.

Future-Proofing Your Installation

Plan for long-term performance and adaptability:

- Choose panels with adaptable finishes that can be easily updated or refinished in the future.

- Consider the potential for building expansions or modifications when planning panel layouts.

- Stay informed about advancements in insulated panel technology and consider upgrades when beneficial.

- Document all maintenance and repair activities for future reference and warranty purposes.

Conclusion

Installing insulated sandwich wall panels like a pro requires careful planning, attention to detail, and adherence to best practices. By following the comprehensive guide outlined in this article, you can ensure a successful installation that maximizes the panels' energy efficiency, durability, and aesthetic appeal. Remember to prioritize regular maintenance and be prepared to address potential issues promptly to extend the lifespan of your panels. With proper care and attention, insulated sandwich wall panels can provide long-lasting performance and contribute significantly to the overall efficiency and comfort of your building.

For more information on insulated sandwich wall panels and other exterior cladding and facade solutions, don't hesitate to contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to assist you with your building material needs and help you achieve the best results for your construction projects.

References

1. Mohsen, M., & Akash, B. A. (2001). "Some prospects of energy savings in buildings." Energy Conversion and Management, 42(11), 1307–1315.

2. Ghosh, S. K. (2003). Design Guide for Precast Insulated Sandwich Panels. Precast/Prestressed Concrete Institute (PCI).

3. International Organization for Standardization (ISO). (2017). ISO 13789:2017 — Thermal performance of buildings — Transmission and ventilation heat transfer coefficients — Calculation method.

4. Drysdale, D. (2011). An Introduction to Fire Dynamics (3rd ed.). Wiley-Blackwell.

5. Teng, J. G., Yu, T., & Fernando, D. (2007). "Strengthening of steel structures with fiber-reinforced polymer composites." Journal of Constructional Steel Research, 63(6), 681–689.

6. Straube, J., & Burnett, E. (2005). Building Science for Building Enclosures. Building Science Press.