Understanding the Basics of PU Insulation Panels

What Are PU Insulation Panels?

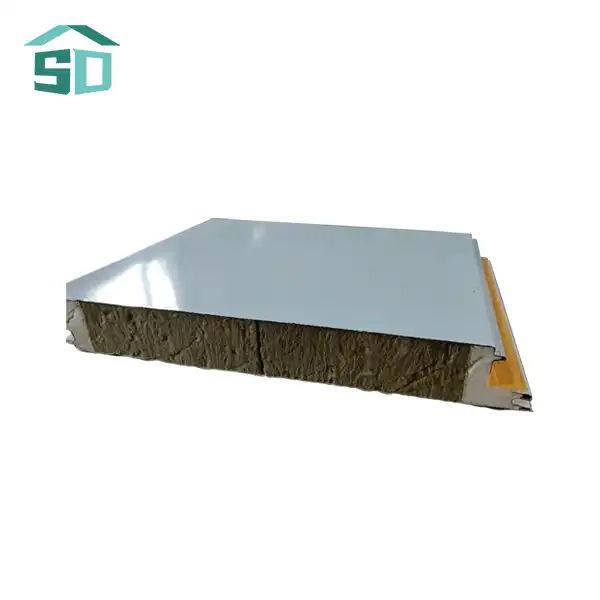

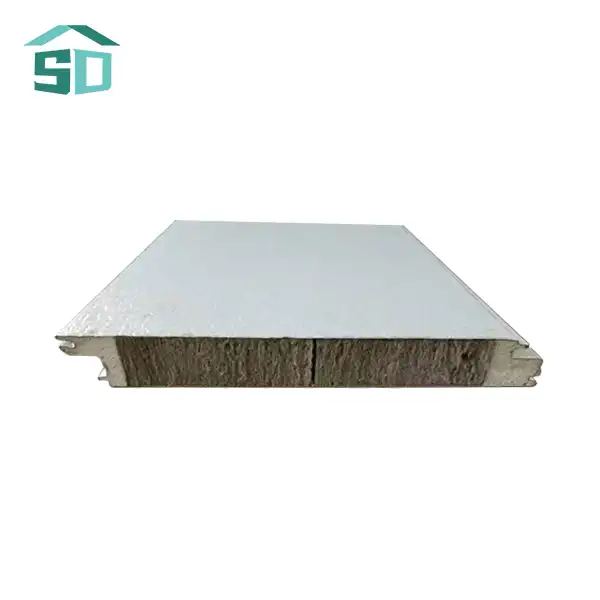

PU insulation panels, short for polyurethane insulation panels, are high-performance building materials designed to provide superior thermal insulation for both interior and exterior applications. These panels consist of a rigid polyurethane foam core sandwiched between two layers of protective materials, typically metal or other durable surfaces.

Key Components and Structure

The structure of PU insulation panels is engineered for optimal performance. The core is made of closed-cell polyurethane foam, known for its exceptional insulating properties. This core is encased in protective layers, which can vary in thickness from 0.23mm to 0.27mm, depending on the specific requirements of the project. The overall thickness of the panels ranges from 10mm for interior applications to 16mm or 20mm for exterior use.

Applications in Construction

PU insulation panels are incredibly versatile, finding applications in a wide range of construction projects. They are suitable for residential complexes, offices, villas, gardens, historic building renovations, municipal buildings, and even security kiosks. Their adaptability makes them a favorite among architects and builders who seek both performance and aesthetic appeal in their designs.

Evaluating Technical Specifications for Optimal Performance

Thermal Properties: The Heart of Insulation

When selecting PU insulation panels, thermal performance is paramount. Look for panels with a low thermal conductivity, ideally around 0.018W/m.k, as this indicates superior insulating capabilities. The thermal resistance (R-value) is another crucial factor, with top-performing panels offering values around 2.09m2k/w. These properties ensure that the panels effectively maintain desired temperatures, reducing energy costs and enhancing indoor comfort.

Fire Safety and Resistance

Safety should never be compromised in construction. PU insulation panels with fire-protection ratings of B1 or B2 offer enhanced safety features. These ratings indicate that the panels have been tested and certified to meet stringent fire safety standards, providing peace of mind for both builders and occupants.

Weatherproofing and Durability

For exterior applications, weatherproofing is essential. Look for panels with a waterproof rate of 0.0008 or lower, ensuring excellent protection against moisture infiltration. Wind resistance is another critical factor, especially for high-rise or exposed buildings. Panels with a wind resistance of 8.0 Kpa or higher are suitable for most applications, offering stability and longevity even in challenging weather conditions.

Structural Integrity

The compressive strength of PU insulation panels is a key indicator of their structural integrity. Panels with a compressive strength of 52.7kpa or higher can withstand significant loads without deformation, making them suitable for a variety of applications, including flooring and roofing.

Practical Considerations for Project Implementation

Customization and Design Flexibility

One of the standout features of PU insulation panels is their customizability. They can be tailored to meet specific project requirements, with customizable lengths and widths to fit various spaces. For exterior applications, panels are typically available in widths of 383 mm, while interior panels often come in 450 mm widths. This flexibility allows for seamless integration into diverse architectural designs, supporting creative solutions for modern facades and interiors while maintaining thermal performance and visual harmony.

Installation and Maintenance

The installation process for PU insulation panels is designed to be straightforward and efficient. It typically involves four main steps: preparation of the surface, cutting panels to size if necessary, fixing them in place using appropriate fasteners and adhesives, and finally, sealing the joints for optimal performance. The lightweight nature of these panels contributes to easier handling and installation, reducing labor costs and project timelines, while also simplifying potential future modifications or repairs.

Environmental Impact and Sustainability

As sustainability becomes increasingly important in construction, it's crucial to consider the environmental impact of building materials. PU insulation panels are often made with environmentally friendly materials and contribute to green building initiatives. Their energy-efficient properties also help reduce the carbon footprint of buildings over their lifetime, making them a sustainable choice for forward-thinking projects. Additionally, the panels’ durability minimizes waste by reducing the frequency of replacements, supporting responsible resource use in construction.

Cost-Effectiveness and Long-Term Value

While the initial cost of PU insulation panels may be higher than some alternatives, their long-term value is significant. The superior insulation properties lead to substantial energy savings over time, reducing operational costs for building owners. Additionally, their durability and resistance to weathering, corrosion, and UV damage ensure a longer lifespan, minimizing the need for replacements or repairs.

Compliance with Building Codes and Standards

When selecting PU insulation panels, it's essential to ensure they comply with local building codes and industry standards. This includes meeting required thermal performance metrics, fire safety regulations, and structural integrity standards. Working with reputable manufacturers who provide comprehensive product documentation and certifications can simplify this process and ensure your project meets all necessary requirements.

Conclusion

Choosing the best PU insulation panels for your projects in 2025 requires careful consideration of various factors, from thermal performance and fire resistance to customization options and environmental impact. By focusing on high-quality panels with superior technical specifications and practical benefits, you can ensure your construction projects are energy-efficient, safe, and sustainable.

Remember to consider the specific needs of your project, local building codes, and long-term cost-effectiveness when making your selection. For expert advice and high-quality PU insulation panels that meet the most demanding requirements, don't hesitate to reach out to us at info@sdqsc.com. Our team is ready to help you find the perfect insulation solution for your next project.