The Science Behind Insulated Sandwich Wall Panels

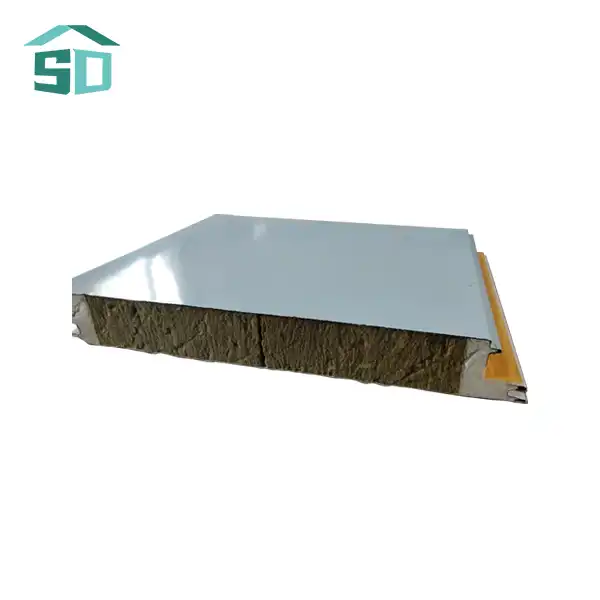

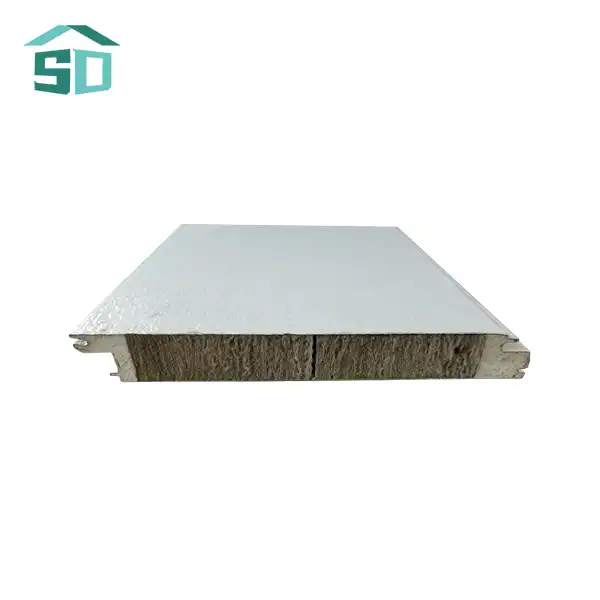

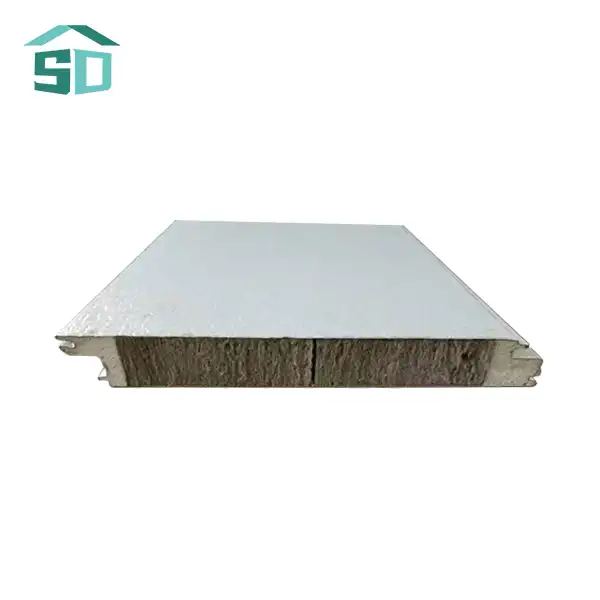

Insulated sandwich wall panels are engineered to maximize energy efficiency through their unique construction. These panels typically consist of two outer layers of durable material, such as steel or aluminum, with a core of high-performance insulation. This sandwich-like structure is the key to their exceptional thermal properties.

Thermal Performance and Energy Savings

The insulation core of these panels plays a crucial role in their energy-saving capabilities. With a thermal conductivity as low as 0.018W/m.k, these panels effectively minimize heat transfer between the interior and exterior of a building. This results in a thermal resistance of 2.09m2k/w, ensuring that indoor temperatures remain stable regardless of external conditions. The superior insulation properties translate directly into reduced energy consumption for heating and cooling, leading to significant cost savings over time.

Durability and Weather Resistance

Beyond their insulation properties, insulated sandwich wall panels are designed to withstand various environmental challenges. With a wind resistance of 8.0 Kpa, these panels can endure severe weather conditions without compromising their structural integrity. The panels also boast an impressive waterproof rate of 0.0008, effectively protecting the building's interior from moisture infiltration. This combination of durability and weather resistance ensures that the panels maintain their energy-saving properties over an extended period, making them a reliable long-term solution for energy-efficient construction.

Versatility in Design and Application

One of the most appealing aspects of insulated sandwich wall panels is their adaptability to various architectural styles and building requirements. This versatility makes them an excellent choice for a wide range of construction projects.

Customizable Dimensions and Finishes

Protects sandwich divider boards offer adaptability in terms of estimate and appearance. With customizable lengths and widths (outside 383mm, insides 450mm), these boards can be custom fitted to fit particular building plans. The boards are accessible in different thicknesses, with insides alternatives at 10mm and outside choices of 16mm or 20mm. This run of measurements permits planners and builders to optimize the panels' execution for diverse climate zones and building sorts.

Moreover, the panels' surface materials, available in thicknesses of 0.23mm, 0.25mm, and 0.27mm, can be finished in a wide variety of colors, textures, and patterns to suit different design needs. This high level of customization allows architects and homeowners to achieve the desired visual appeal without compromising the panels' core benefits, such as insulation performance and long-term energy efficiency.

Wide-ranging Applications

The versatility of insulated sandwich wall panels extends to their applications. These panels are suitable for use in:

- Residential complexes

- Office buildings

- Villas and custom homes

- Garden structures

- Historic building renovations

- Municipal buildings

- Security kiosks

This wide range of applications demonstrates the panels' ability to meet diverse construction needs while consistently delivering energy-saving benefits.

Installation and Long-term Performance

The effectiveness of insulated sandwich wall panels in saving energy is not only due to their inherent properties but also their proper installation and long-term performance.

Efficient Installation Process

Installing insulated sandwich wall panels is a straightforward and efficient process, contributing to reduced construction time and labor costs. The installation typically follows these steps:

1.Preparation: Ensuring the surface is clean, dry, and free from debris.

2.Layout: Planning the panel arrangement according to the building design.

3.Fastening: Using appropriate fasteners to secure the panels in place, ensuring a tight fit.

4.Sealing: Applying sealants where necessary to prevent air and water ingress.

5.Finishing: Completing the installation with any desired surface treatments or finishes.

This streamlined installation process not only saves time but also helps maintain the panels' energy-saving properties by ensuring proper fit and sealing.

Durability and Fire Safety

The long-term execution of ensures sandwich divider sheets is progressed by their remarkable quality and built-in security highlights. With a compressive quality of 52.7 kPa, these sheets are able of withstanding significant fundamental loads without bowing or mutilation. This ensures the insightfulness of the separator layer remains uncompromised, keeping up perfect warm execution over time and contributing to the by and huge quality, consistent quality, and imperativeness adequacy of the building envelope.

Safety is also a paramount concern in building construction. Insulated sandwich wall panels address this with fire-protection ratings of B1/B2, providing an additional layer of safety to the structure. This fire resistance not only protects the building and its occupants but also helps maintain the panels' energy-saving capabilities even in extreme conditions.

Eco-friendly and Cost-effective Solution

Protects sandwich divider boards speak to an eco-friendly choice in building materials. Their energy-saving properties contribute to diminished carbon emanations over the lifetime of the building. Furthermore, the panels' strength and moo support prerequisites interpret into a cost-effective arrangement for high-performance divider frameworks, advertising long-term esteem to building proprietors and tenants.

Conclusion

Insulated sandwich wall panels offer a compelling solution for energy-efficient construction. Their superior insulation properties, combined with durability, versatility, and ease of installation, make them an ideal choice for a wide range of building projects. As the construction industry continues to prioritize energy conservation and sustainable practices, these panels stand out as a proven technology that delivers tangible benefits in terms of energy savings, comfort, and long-term performance.

For those looking to enhance their building's energy efficiency with high-quality insulated sandwich wall panels, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and superior products. To learn more about our energy-saving wall panel solutions and how they can benefit your next construction project, please contact us at info@sdqsc.com.