Factors Affecting the Longevity of Polyurethane Insulation Panels

Understanding the factors that impact the durability of polyurethane insulation panels is crucial for maximizing their lifespan and performance. Let's explore the key elements that influence how well these panels withstand the test of time:

Environmental Conditions

The environment in which polyurethane insulation panels are installed plays a significant role in their longevity. Extreme temperatures, humidity levels, and exposure to UV radiation can all affect the panels' performance over time. In regions with harsh climates, such as areas prone to severe heat or cold, the panels may experience more stress and potential deterioration. However, many modern polyurethane insulation panels are engineered to withstand a wide range of environmental conditions, featuring UV-resistant coatings and moisture barriers to enhance their durability.

Installation Quality

The manner in which polyurethane insulation panels are installed is paramount to their long-term effectiveness. Proper installation ensures that the panels are securely fastened, joints are correctly sealed, and there are no gaps or voids that could compromise their insulating properties. Professional installation by experienced technicians can significantly extend the lifespan of these panels by minimizing the risk of moisture intrusion, air leakage, and structural issues.

Maintenance Practices

Regular maintenance is key to preserving the integrity of polyurethane insulation panels. This includes periodic inspections to check for any signs of damage, such as cracks, gaps, or moisture accumulation. Prompt repairs of any identified issues can prevent minor problems from escalating into more serious concerns that could affect the panels' performance. Additionally, keeping the panels clean and free from debris can help maintain their appearance and functionality over time.

Signs of Deterioration in Polyurethane Insulation Panels

While polyurethane insulation panels are known for their resilience, it's important to be aware of potential signs of deterioration. By recognizing these indicators early, property owners and facility managers can take proactive measures to address issues before they become more severe:

Physical Damage

Visible cracks, dents, or punctures in the panels can compromise their insulating capabilities. Such damage may occur due to impacts, settling of the building structure, or extreme weather events. Regular visual inspections can help identify these physical signs of wear and tear, allowing for timely repairs or replacements as needed.

Moisture Intrusion

Water infiltration is a significant concern for any insulation material, including polyurethane panels. Signs of moisture issues may include discoloration, swelling, or a musty odor. Advanced moisture detection techniques, such as infrared thermography, can be employed to identify hidden moisture problems within the insulation system.

Reduced Thermal Performance

A noticeable decrease in the building's energy efficiency or comfort levels could indicate that the insulation panels are no longer performing optimally. This may manifest as higher energy bills or inconsistent indoor temperatures. Conducting periodic energy audits and thermal imaging assessments can help evaluate the ongoing effectiveness of the insulation system.

Strategies to Extend the Lifespan of Polyurethane Insulation Panels

To maximize the longevity and performance of polyurethane insulation panels, consider implementing the following strategies:

Regular Inspections and Maintenance

Establish a regular inspection schedule to thoroughly assess the condition of insulation panels. This should include detailed visual checks to identify physical damage, moisture infiltration, and early signs of wear or degradation. Additionally, it's important to engage qualified professionals periodically to perform more in-depth evaluations using advanced tools like thermal imaging and moisture testing to ensure panels remain effective and intact over time.

Prompt Repairs and Replacements

Address any detected issues promptly to prevent further damage and deterioration of the insulation panels. This may involve sealing minor cracks or gaps, replacing severely damaged sections, or upgrading fastening systems to maintain structural integrity. Timely repairs and replacements are essential to prolong the lifespan of the insulation system and to maintain its thermal performance and energy efficiency over the long term.

Environmental Controls

Implement proactive measures to reduce environmental stressors that can affect insulation panel performance. These measures might include enhancing ventilation to minimize moisture buildup, applying UV-protective coatings on panels exposed to direct sunlight, and improving drainage systems to prevent water accumulation around the panels. Such controls help preserve the insulation's durability and ensure consistent protection against harsh weather conditions.

Conclusion

Polyurethane insulation panels offer exceptional thermal performance and durability, making them a popular choice for a wide range of construction projects. Their ability to maintain effectiveness over extended periods contributes to long-term energy savings and building comfort. By understanding the factors that influence their longevity and implementing proper maintenance strategies, property owners can ensure these panels continue to deliver optimal performance for decades.

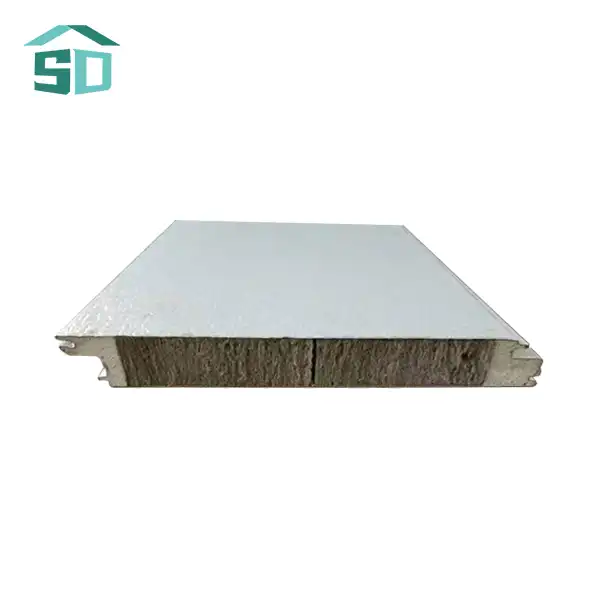

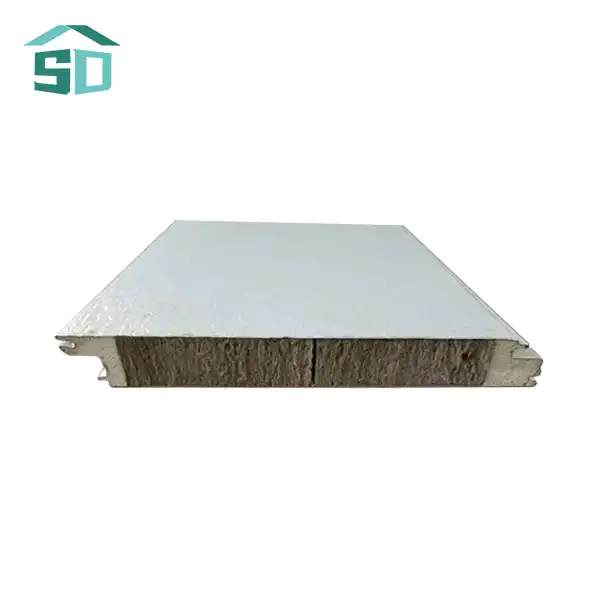

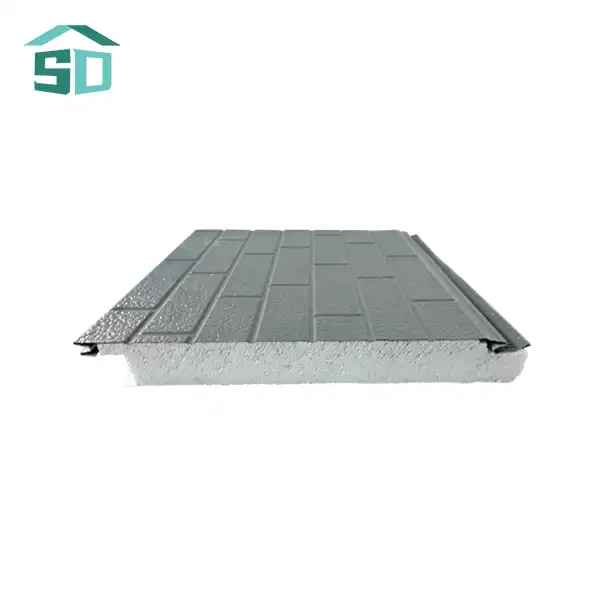

At Weifang Sandong Building Materials Co., Ltd., we specialize in providing high-quality polyurethane insulation panels that are designed for durability and long-lasting performance. Our panels are manufactured using advanced production techniques and undergo rigorous quality control measures to ensure they meet the highest standards of thermal efficiency and structural integrity. From residential complexes to commercial offices and industrial facilities, our versatile insulation solutions are tailored to meet the unique requirements of each project.

For more information about our polyurethane insulation panels and how they can benefit your construction or renovation project, please don't hesitate to contact us at info@sdqsc.com. Our team of experts is ready to assist you in selecting the ideal insulation solution for your specific needs, ensuring optimal energy efficiency and comfort for years to come.