The Core Components of Metal Insulated Sandwich Panels

Metal insulated sandwich panels are engineered to provide superior insulation and structural integrity. The key components that make up these panels include:

Metal Facings: Strength and Aesthetics Combined

The outer layers of metal insulated sandwich panels are typically made from high-quality steel or aluminum. These metal facings offer exceptional durability, protecting the insulation core from external elements. At Weifang Sandong Building Materials Co., Ltd., we utilize advanced production lines to ensure the quality of our steel coils, with strict testing protocols in place for thickness, paint film integrity, and mechanical strength.

The metal facings not only provide structural support but also contribute to the aesthetic appeal of the panels. With a range of colors and patterns available, architects and builders can customize the panels to match their design vision. The versatility of these panels makes them suitable for various applications, including residential complexes, offices, villas, and even historic building renovations.

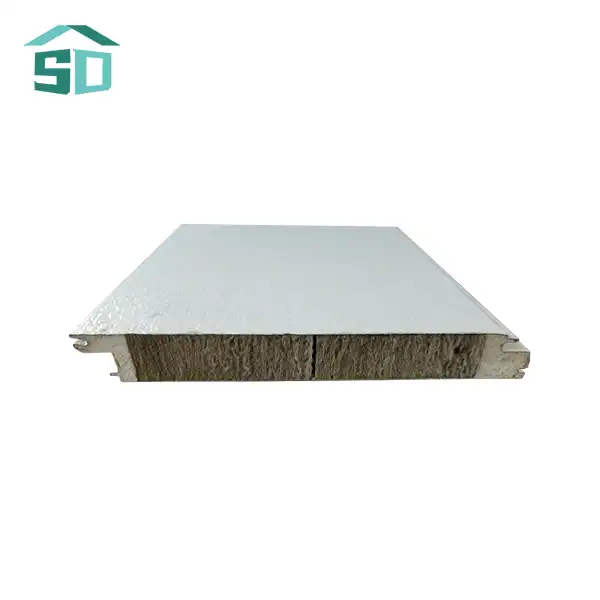

Insulation Core: The Heart of Energy Efficiency

The core of metal insulated sandwich panels is where the magic happens in terms of thermal performance. Typically, the insulation material used is either polyurethane (PU) or polyisocyanurate (PIR). These materials offer exceptional thermal properties, with a thermal conductivity as low as 0.018W/m.k and thermal resistance of 2.09m2k/w, as seen in our high-performance panels.

The insulation core not only helps maintain ideal temperatures within buildings but also contributes to significant energy savings. This eco-friendly approach aligns with modern sustainable building practices, making metal insulated sandwich panels a preferred choice for environmentally conscious construction projects.

Types of Metal Insulated Sandwich Panels for Walls

When it comes to wall applications, metal insulated sandwich panels offer a variety of options to suit different architectural and functional requirements:

Exterior Wall Panels: Durable and Weather-Resistant

Exterior wall panels are designed to withstand the harshest environmental conditions. With a typical thickness ranging from 16mm to 20mm and a width of 383mm, these panels offer robust protection against the elements. The corrosion-proof design ensures longevity, with panels capable of resisting wind loads up to 8.0 Kpa.

Our outside boards brag a waterproof rate of 0.0008, giving amazing security against dampness penetration. This makes them perfect for utilize in zones inclined to overwhelming precipitation or tall stickiness. The fire-protection rating of B1/B2 advance upgrades the security highlights of these boards, making them reasonable for a wide extend of commercial and mechanical applications.

Interior Wall Panels: Versatile and Aesthetically Pleasing

Interior wall panels offer a balance of insulation and design flexibility. With a typical thickness of 10mm and a width of 450mm, these panels are perfect for creating partitions or enhancing the thermal performance of existing walls. The thinner profile allows for easier installation and minimal impact on interior space.

The customizable aesthetics of interior panels make them a favorite among designers. With a variety of finishes and textures available, these panels can seamlessly integrate into any interior design scheme, from sleek modern offices to cozy residential spaces.

Specialized Metal Insulated Sandwich Panels

Beyond standard wall applications, metal insulated sandwich panels have evolved to meet specific construction needs:

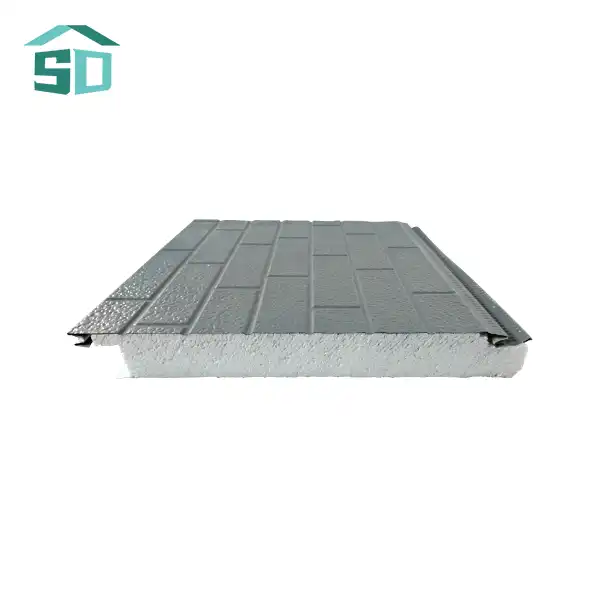

Roof Panels: Combining Insulation with Structural Support

Metal insulated sandwich panels designed for roofing applications offer a unique combination of thermal insulation and load-bearing capacity. These panels typically feature a trapezoidal or ribbed profile on the exterior face, enhancing water drainage and structural integrity.

Roof panels are engineered to withstand significant loads, including snow and wind, while maintaining excellent thermal performance. The compressive strength of 52.7kpa in our panels ensures they can handle the demands of various roofing applications without compromising on insulation efficiency.

Cold Storage Panels: Maintaining Critical Temperatures

For industries requiring precise temperature control, such as food processing or pharmaceutical manufacturing, specialized cold storage panels are available. These panels feature enhanced insulation properties and vapor barriers to prevent condensation and maintain consistent internal temperatures.

Cold storage panels often incorporate food-safe finishes on the interior face, ensuring compliance with hygiene standards. The superior insulation properties of these panels contribute to energy savings in refrigerated environments, making them a cost-effective solution for temperature-sensitive applications.

Acoustic Panels: Combining Insulation with Sound Control

In situations where sound control is vital, acoustic metal protects sandwich boards offer a dual-purpose arrangement. These boards join sound-absorbing materials inside the separator center or as an extra layer, making a difference to decrease commotion transmission between spaces.

Acoustic panels are particularly valuable in commercial and industrial settings, such as offices, schools, or manufacturing facilities. By combining thermal insulation with sound control, these panels contribute to creating comfortable and productive environments.

Conclusion

The diverse range of metal insulated sandwich panels available today offers solutions for virtually every building application. From exterior walls that withstand the elements to specialized panels for cold storage and acoustic control, these innovative materials are shaping the future of sustainable construction. As we continue to push the boundaries of energy efficiency and building performance, metal insulated sandwich panels will undoubtedly play a crucial role in creating smarter, more sustainable structures.

For more information on our range of metal insulated sandwich panels and how they can benefit your next construction project, please don't hesitate to contact us at info@sdqsc.com. Our team of experts at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect solution for your building needs.