When it comes to enhancing the aesthetics and functionality of your building's exterior, choosing the right cladding is crucial. Exterior wall cladding not only protects your structure from the elements but also adds a touch of style and personality. However, finding affordable options that don't skimp on quality can be a challenge. In this comprehensive guide, we'll explore cost-effective exterior wall cladding solutions that offer both durability and visual appeal.

Introducing Exterior Wall Cladding: Function Meets Form

Exterior wall cladding serves as the protective skin of a building, shielding it from weather, moisture, and other environmental factors. Beyond its practical purpose, cladding plays a significant role in defining a structure's architectural character. The right cladding can transform a plain facade into a striking visual statement, enhancing curb appeal and potentially increasing property value.

The Multifaceted Benefits of Quality Exterior Cladding

Investing in high-quality exterior wall cladding offers numerous advantages:

- Weather Protection: Shields the building from rain, wind, and UV radiation

- Thermal Insulation: Improves energy efficiency by reducing heat transfer

- Noise Reduction: Helps dampen external sounds for a quieter interior

- Aesthetic Enhancement: Elevates the visual appeal of the structure

- Low Maintenance: Quality cladding requires minimal upkeep over time

While premium materials often come with a hefty price tag, there are affordable exterior wall cladding options that don't compromise on these essential benefits.

Affordable Exterior Wall Cladding Materials: Budget-Friendly Excellence

Let's delve into some cost-effective exterior wall cladding materials that offer exceptional value without breaking the bank:

Vinyl Siding: The Versatile Virtuoso

Vinyl siding remains a popular choice for exterior wall cladding due to its affordability and versatility. Modern vinyl siding offers:

- Wide range of colors and textures, including wood-grain finishes

- Excellent durability and weather resistance

- Low maintenance requirements—just occasional cleaning

- Good insulation properties for energy efficiency

- Easy installation, reducing labor costs

While vinyl may not have the premium feel of some materials, advancements in manufacturing have greatly improved its aesthetic appeal and performance.

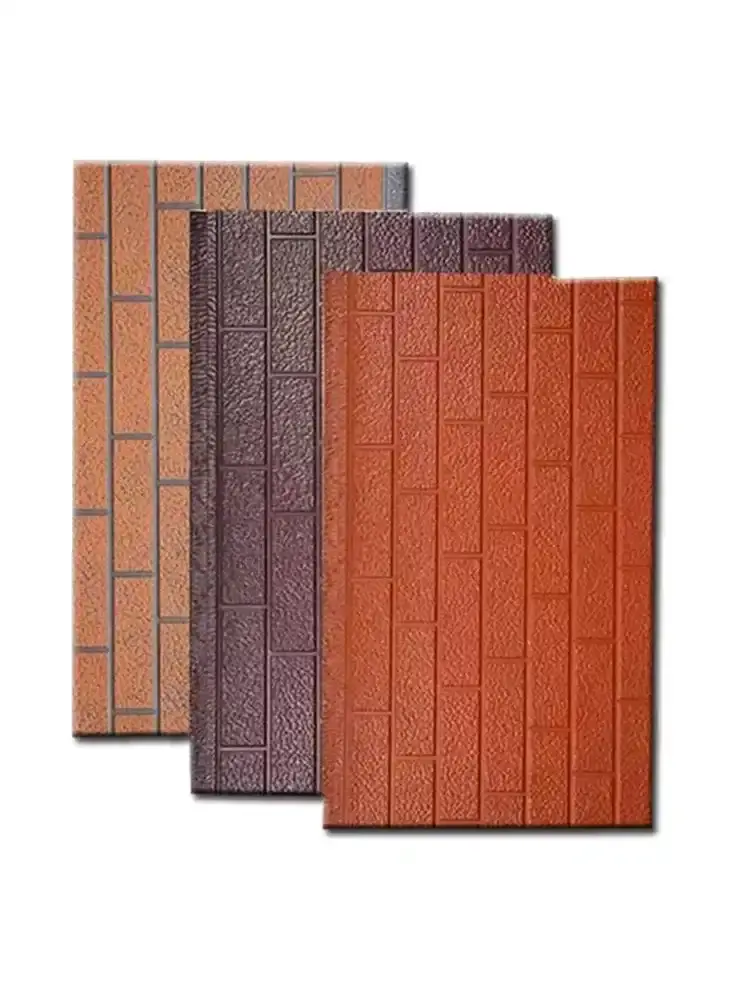

Fiber Cement: The Durable Doppelganger

Fiber cement cladding offers a fantastic balance of affordability and durability. This composite material mimics the look of wood or masonry at a fraction of the cost. Benefits include:

- Exceptional resistance to fire, rot, and pests

- Long lifespan with minimal maintenance

- Versatile design options, including textured finishes

- Paintable surface for customization

- Eco-friendly composition using sustainable materials

While slightly pricier than vinyl, fiber cement's longevity and low maintenance needs make it a cost-effective exterior wall cladding option in the long run.

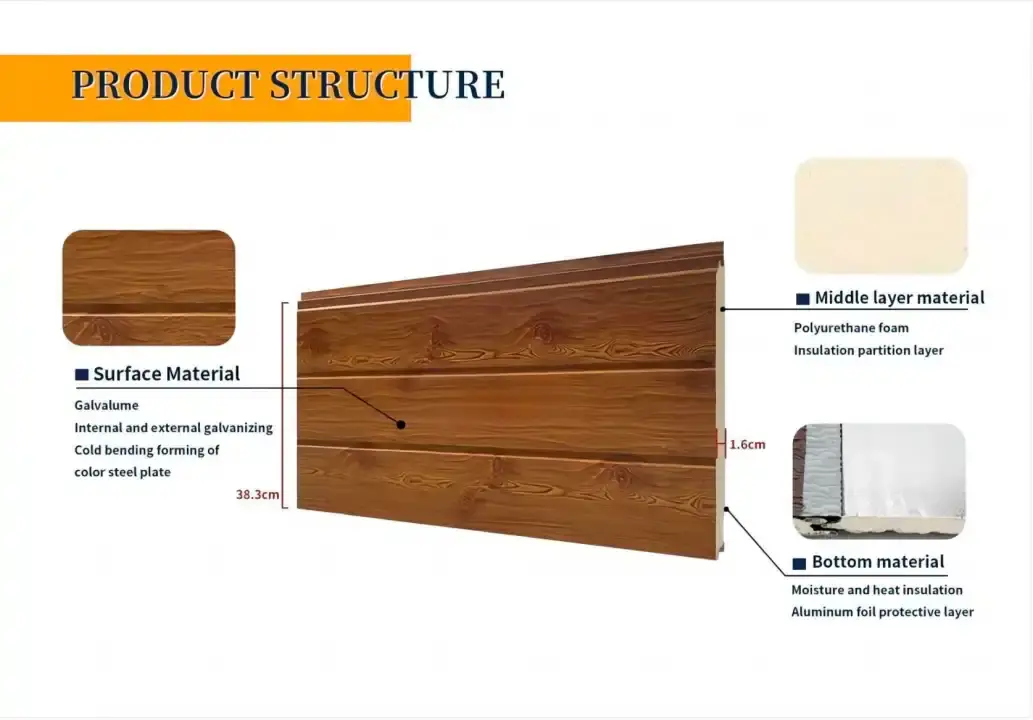

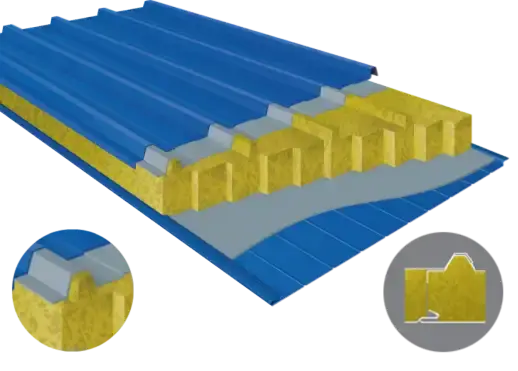

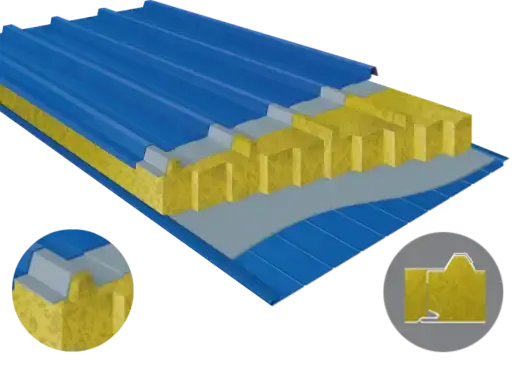

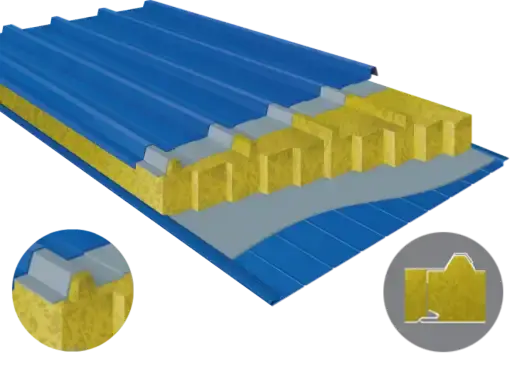

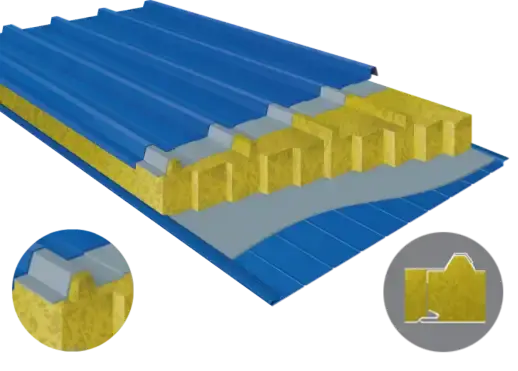

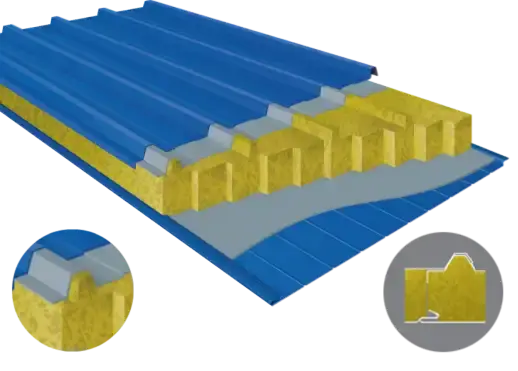

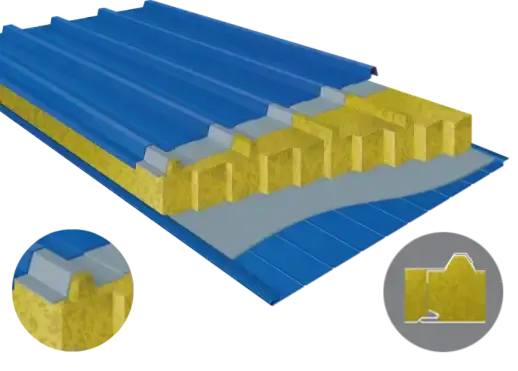

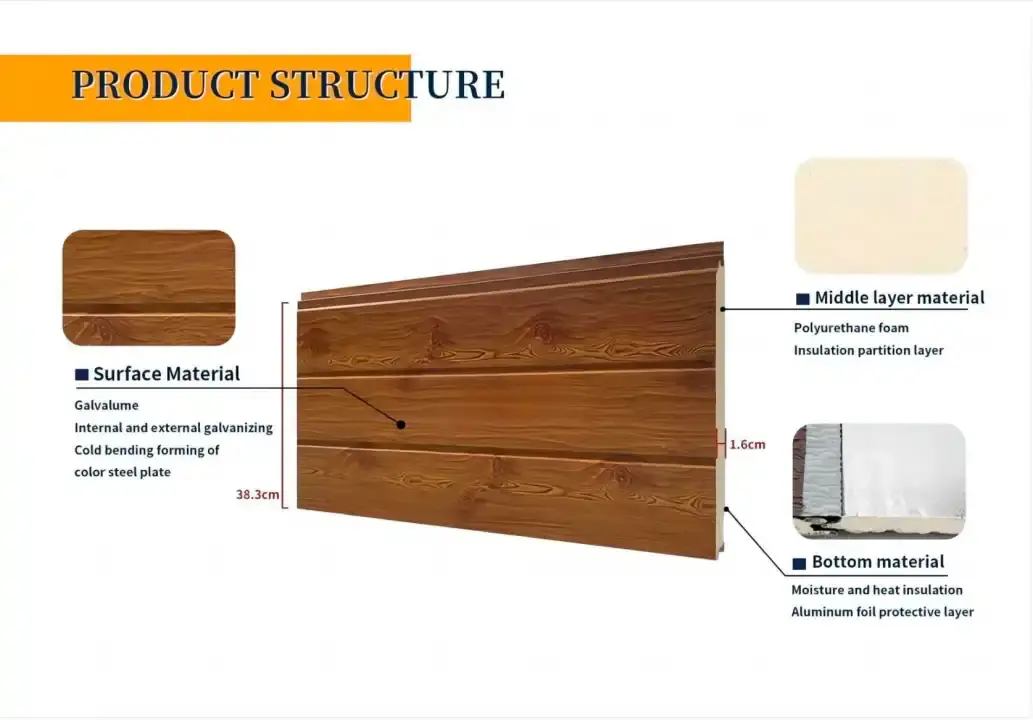

Metal Siding: The Modern Marvel

Metal siding, particularly aluminum and steel, offers a contemporary look with impressive durability. Key advantages include:

- Excellent weather resistance and longevity

- Lightweight nature for easy installation

- Recyclable material, appealing to eco-conscious consumers

- Low maintenance requirements

- Fire-resistant properties for enhanced safety

While the initial cost may be higher than some options, metal siding's durability and minimal upkeep make it an economical choice over time.

Maximizing Value: Tips for Affordable Exterior Wall Cladding Installation

Choosing cost-effective materials is just the first step. To truly maximize the value of your exterior wall cladding project, consider these tips:

Proper Planning: The Foundation of Success

Before embarking on your exterior wall cladding project, thorough planning is essential:

- Assess your building's specific needs and environmental conditions

- Consider long-term maintenance requirements and costs

- Research local building codes and regulations

- Obtain multiple quotes from reputable contractors

- Factor in potential energy savings from improved insulation

Careful planning helps avoid costly mistakes and ensures you choose the most suitable and affordable exterior wall cladding for your project.

DIY vs. Professional Installation: Weighing the Options

While DIY installation may seem like a cost-saving measure, it's not always the most economical choice in the long run. Consider:

- Your skill level and experience with similar projects

- The complexity of the installation process for your chosen material

- The potential cost of mistakes or improper installation

- The value of warranties often provided with professional installation

- The time investment required for a DIY project

In many cases, professional installation by an experienced exterior wall cladding factory or contractor can provide better results and long-term value, despite the higher upfront cost.

Maintenance Matters: Preserving Your Investment

To ensure your affordable exterior wall cladding remains cost-effective over time:

- Follow manufacturer-recommended maintenance schedules

- Address any damage or wear promptly to prevent larger issues

- Clean the cladding regularly to maintain its appearance and integrity

- Inspect for potential issues annually, especially after severe weather events

- Consider applying protective coatings to extend the life of your cladding

Proper maintenance not only preserves the appearance of your exterior wall cladding but also extends its lifespan, maximizing your investment.

Conclusion

Affordable exterior wall cladding options that don't compromise on quality do exist. By choosing materials like vinyl, fiber cement, or metal siding, and implementing smart installation and maintenance strategies, you can achieve a durable, attractive facade without overspending. Remember, the key to maximizing value lies in careful planning, considering long-term costs, and balancing affordability with performance. With the right approach, you can enhance your building's protection, efficiency, and aesthetics without breaking the bank.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of balancing cost and quality in exterior wall cladding. Our metal siding panels offer an excellent solution for both new construction and renovation projects, combining affordability with durability, fire resistance, and aesthetic versatility. Whether you're working on a residential home, office building, or commercial space, our exterior wall cladding products provide the perfect blend of form and function. Interested in learning more about our affordable, high-quality cladding solutions? Contact us at info@sdqsc.com to discuss how we can enhance your next project.

FAQ

What is the most cost-effective exterior wall cladding material?

Vinyl siding is often considered the most cost-effective option due to its low initial cost and minimal maintenance requirements.

How long does affordable exterior wall cladding typically last?

The lifespan varies by material, but quality vinyl siding can last 20-40 years, fiber cement 50+ years, and metal siding 40-70 years with proper maintenance.

Can I install exterior wall cladding over existing siding?

In some cases, yes, but it's crucial to assess the condition of the existing siding and underlying structure first. Professional consultation is recommended.

How does exterior wall cladding affect energy efficiency?

Quality cladding can significantly improve a building's energy efficiency by providing an additional layer of insulation, potentially reducing heating and cooling costs.

References

1. Building Science Corporation. (2021). "Cladding Systems."

2. U.S. Department of Energy. (2022). "Wall Insulation."

3. National Association of Home Builders. (2023). "Exterior Cladding."

4. Vinyl Siding Institute. (2023). "About Vinyl Siding."

5. James Hardie Industries. (2023). "Fiber Cement Siding."