The Science Behind Metal Sheet PU Sandwich Panels

Composition and Structure

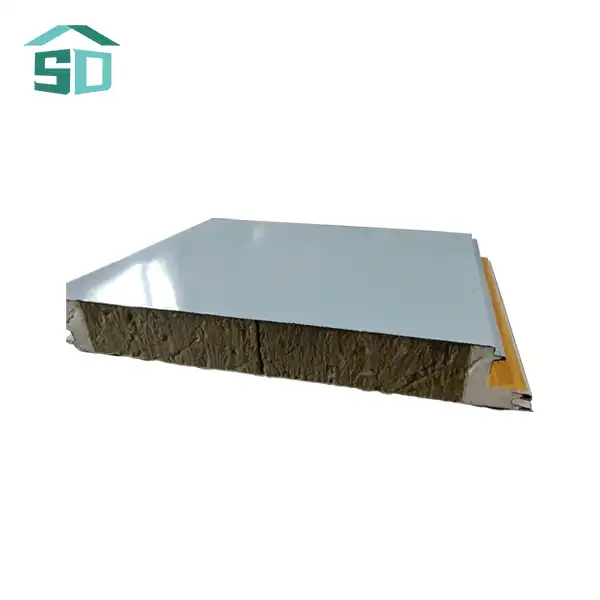

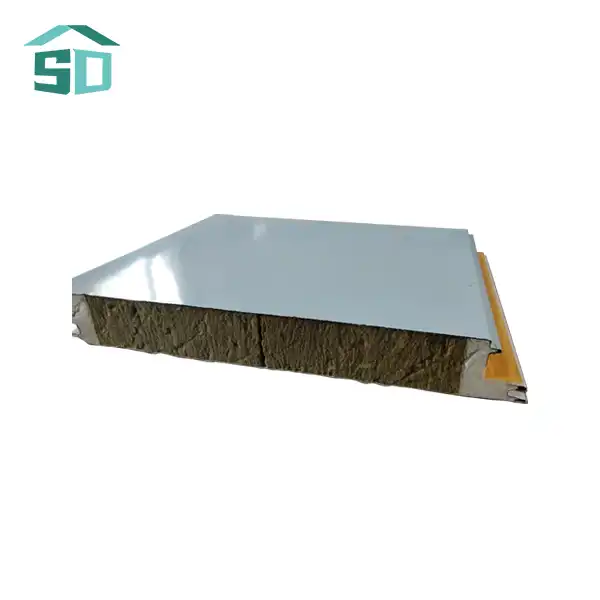

Metal sheet PU sandwich panels are a marvel of modern construction technology. These panels consist of two metal sheets that sandwich a core of polyurethane foam. The metal sheets, typically made from steel or aluminum, provide strength and durability, while the PU foam core offers exceptional insulation properties. This unique composition creates a lightweight yet robust panel that excels in thermal performance.

The thickness of the boards can be customized to suit distinctive applications. For insides utilize, boards are frequently 10mm thick, whereas outside applications may require thicker boards of 16mm or 20mm. The width of the boards too changes, with outside boards regularly measuring 383mm wide and insides boards 450mm wide. The surface fabric thickness ranges from 0.23mm to 0.27mm, giving adaptability in plan and application.

Thermal Performance

The thermal performance of metal sheet PU sandwich panels is truly remarkable. With a thermal conductivity of just 0.018W/m.k, these panels offer superior insulation compared to many traditional building materials. This low thermal conductivity translates to a high thermal resistance of 2.09m2k/w, effectively minimizing heat transfer through walls and roofs.

The exceptional insulation properties of these panels stem from the closed-cell structure of the polyurethane foam core. This structure traps tiny pockets of air, creating a formidable barrier against heat flow. As a result, buildings equipped with metal sheet PU sandwich panels maintain a more stable internal temperature, reducing the load on heating and cooling systems and leading to significant energy savings.

Advantages Beyond Energy Efficiency

Durability and Weather Resistance

While energy efficiency is a primary benefit of metal sheet PU sandwich panels, their advantages extend far beyond thermal performance. These panels boast exceptional durability, thanks to the fusion of metal sheets and polyurethane foam. This combination results in a product that can withstand harsh environmental conditions without compromising its structural integrity.

The panels exhibit impressive weather resistance properties. With a waterproof rate of 0.0008, they provide excellent protection against moisture infiltration, preventing water damage and mold growth. Additionally, their wind resistance of 8.0 Kpa ensures that they can withstand high wind loads, making them suitable for use in areas prone to severe weather conditions.

Fire Safety and Structural Strength

Safety is paramount in building design, and metal sheet PU sandwich panels deliver on this front as well. These panels come with a fire-protection rating of B1/B2, indicating their ability to resist fire spread and contribute to overall building safety. This feature is particularly crucial in commercial and industrial settings where fire safety regulations are stringent.

The basic quality of these boards is another critical include. With a compressive quality of 52.7kpa, they can bear critical loads without distortion. This quality, combined with their lightweight nature, makes them an perfect choice for a wide extend of development ventures, from private complexes to office buildings and mechanical offices.

Versatility in Application and Design

Aesthetic Flexibility

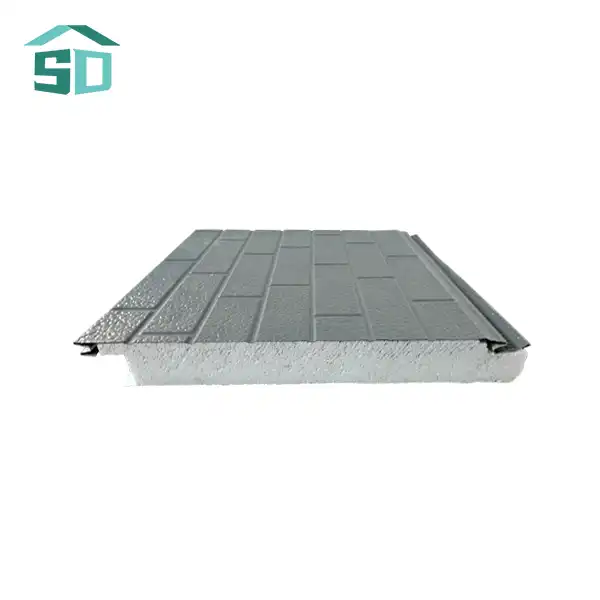

Metal sheet PU sandwich sheets offer more than reasonable utilitarian benefits; they as well grant organizers and modelers with a canvas for creative expression. These sheets can be customized in a collection of colors and plans, allowing for the creation of apparently striking outsides that overhaul the in common classy ask of a building.

The flexibility of these boards expands to their application in both insides and outside dividers. For outside utilize, they serve as a successful cladding arrangement, ensuring the building envelope whereas contributing to its visual personality. In insides applications, they can be utilized to make parcel dividers or enriching components, advertising both separator and stylish esteem.

Adaptability to Various Building Types

The adaptability of metal sheet PU sandwich panels makes them suitable for a wide range of building types and renovation projects. From modern office complexes to historic building renovations, these panels can be integrated seamlessly into diverse architectural styles. Their use in residential villas, municipal buildings, and even security kiosks demonstrates their versatility in meeting varied construction needs.

Designers and builders progressively select metal sheet PU sandwich boards for their prevalent execution and stylish offer. The panels' capacity to combine vitality effectiveness, strength, and plan adaptability makes them a favored choice in modern development ventures. Whether it's a modern construct or a redesign, these boards offer a arrangement that meets both utilitarian necessities and stylish goals.

Conclusion

Metal sheet PU sandwich panels represent a significant advancement in building technology, offering a compelling solution for those seeking to maximize energy savings without compromising on durability or aesthetics. Their exceptional thermal performance, combined with strength, fire resistance, and design flexibility, makes them an invaluable asset in modern construction.

As the construction industry continues to evolve towards more sustainable and energy-efficient practices, the role of innovative materials like metal sheet PU sandwich panels becomes increasingly crucial. By choosing these panels, builders and property owners not only contribute to energy conservation but also invest in the long-term performance and value of their buildings.

For those interested in exploring the benefits of metal sheet PU sandwich panels for their next construction or renovation project, expert guidance is available. To learn more about how these panels can enhance your building's energy efficiency and overall performance, contact us at info@sdqsc.com. Our team of specialists is ready to provide detailed information and tailored solutions to meet your specific needs.