When it comes to enhancing the exterior of your home or commercial building, the choice between decorative exterior wall panels and traditional siding can be a challenging one. Both options offer unique benefits and aesthetic appeal, but which is the right choice for your project? In this comprehensive guide, we'll explore the key differences, advantages, and considerations for both decorative exterior wall panels and traditional siding, helping you make an informed decision for your next construction or renovation project.

Understanding Decorative Exterior Wall Panels

What Are Decorative Exterior Wall Panels?

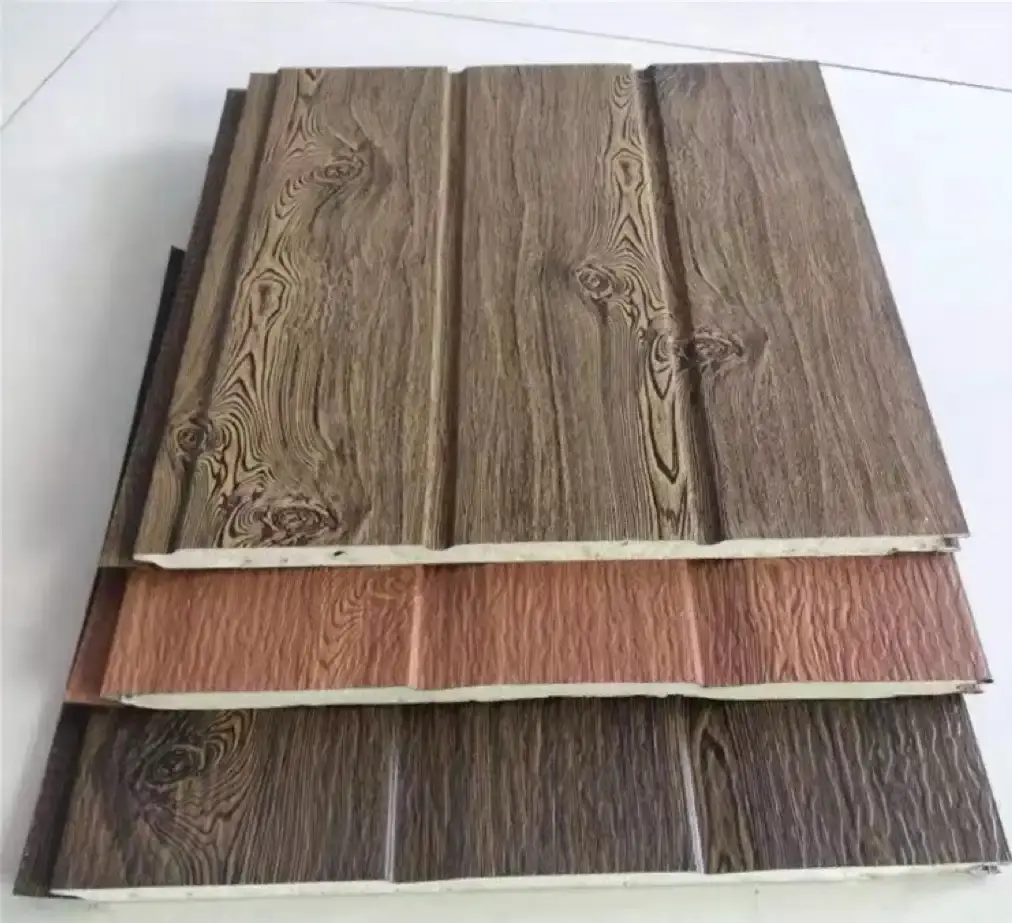

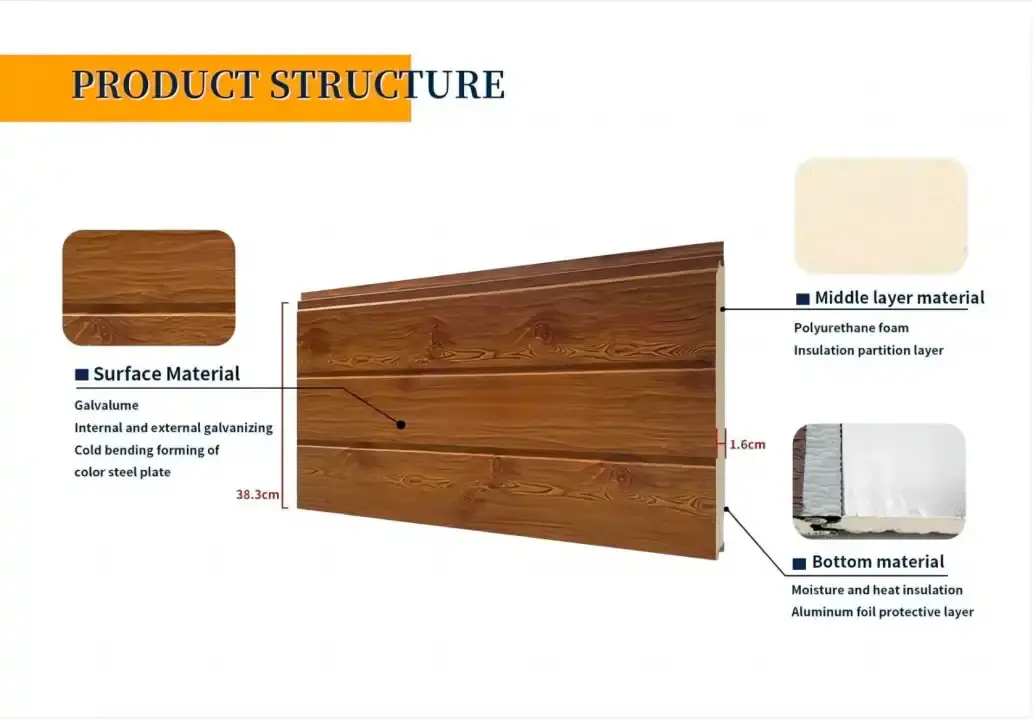

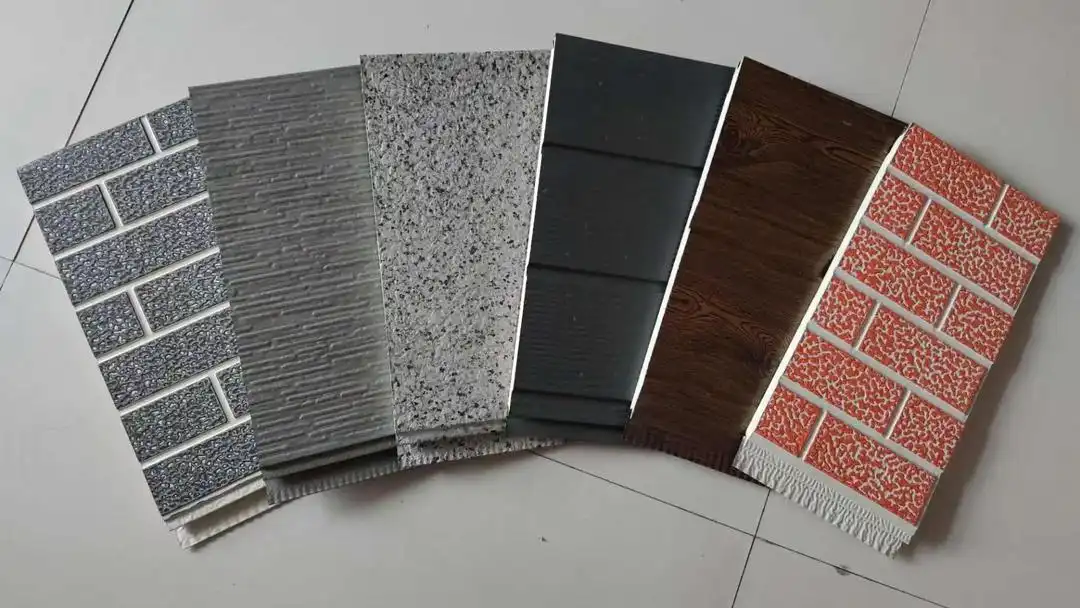

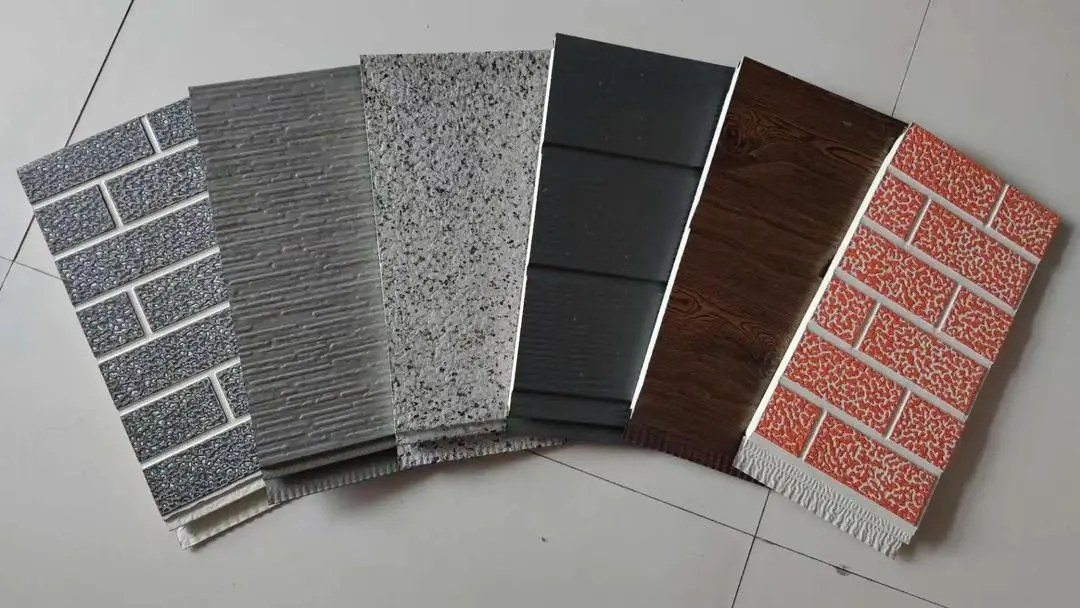

Decorative exterior wall panels are innovative building materials designed to enhance the aesthetic appeal and functionality of a structure's exterior. These panels, often manufactured by specialized decorative exterior wall panels manufacturers, combine form and function to provide a modern, sophisticated look while offering superior protection against the elements.

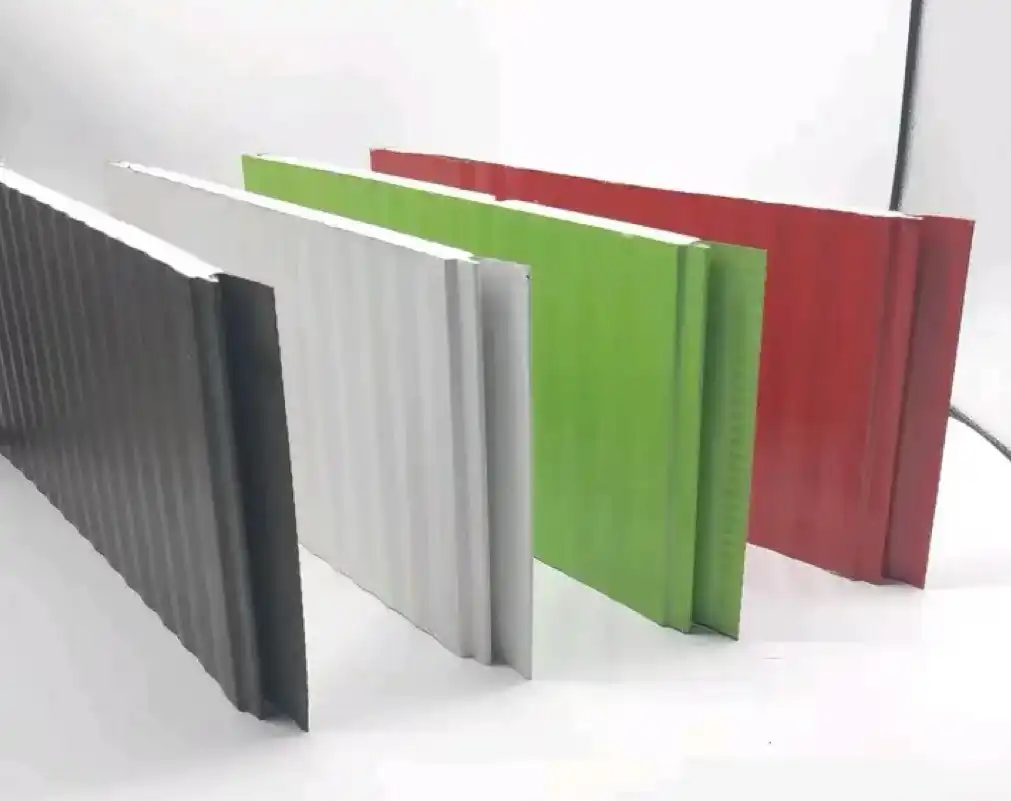

Sandong Building Materials, a leading provider in the field, offers metal siding wall panels that exemplify the best qualities of decorative exterior wall panels. These panels are available in a variety of colors and designs, featuring intricate carved patterns that add a touch of modern sophistication to any exterior.

Benefits of Decorative Exterior Wall Panels

Decorative exterior wall panels offer numerous advantages over traditional siding options:

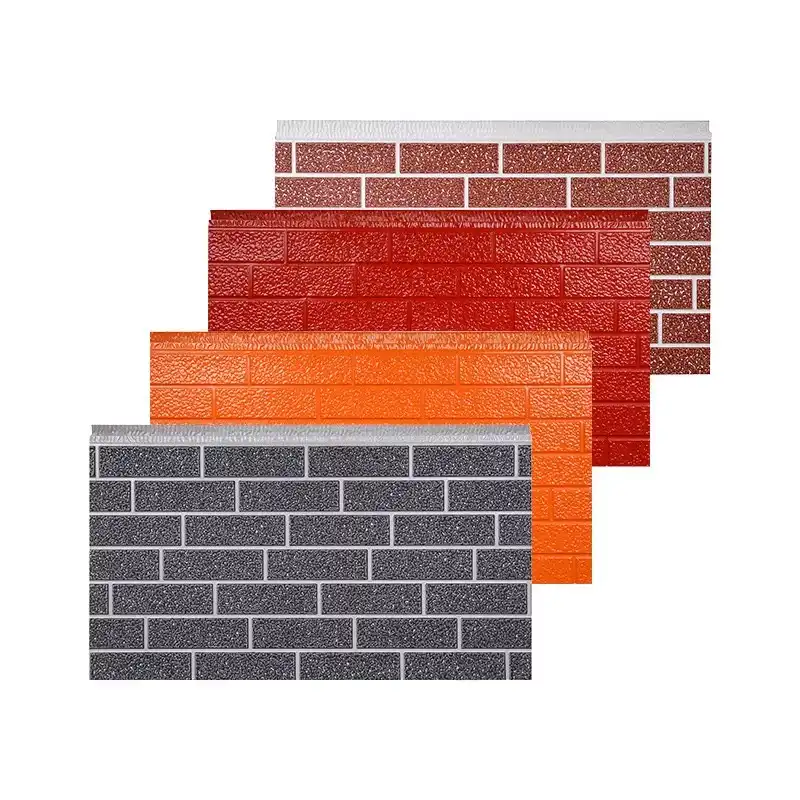

1.Aesthetics:With a wide range of colors, textures, and patterns available, these panels allow for greater creative expression in architectural design.

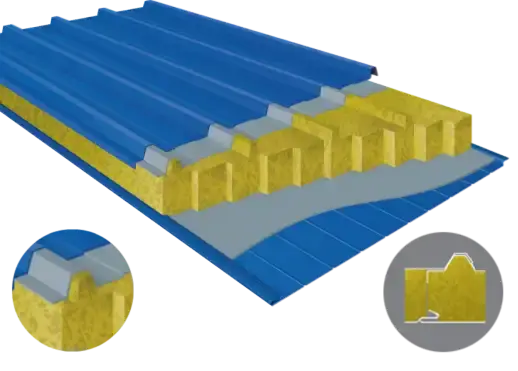

2.Durability:Engineered to withstand harsh weather conditions, including strong winds, heavy rain, and snow, these panels ensure longevity and structural integrity.

3.Fire Resistance:Many decorative panels, like those offered by Sandong Building Materials, are specially treated for optimal flame retardancy, meeting strict safety standards and achieving high fire protection levels.

4.Easy Installation:The lightweight design and customizable features of these panels significantly reduce construction time and labor costs.

5.Low Maintenance:Resistant to fading, chipping, and peeling, decorative exterior wall panels maintain their allure for years with minimal upkeep requirements.

Applications of Decorative Exterior Wall Panels

The versatility of decorative exterior wall panels makes them suitable for a wide range of applications, including:

- Office Buildings

- Churches and Temples

- Retail Shops

- Utility Buildings

- Warehouses

- Residential Homes

- Metal Building Systems

- Schools

- Manufacturing Facilities

- Airport Facilities

- Equipment Buildings

- Apartment Buildings

Traditional Siding: A Closer Look

Types of Traditional Siding

Traditional siding has been a staple in construction for decades, offering a classic look and reliable protection. Common types include:

- Vinyl Siding: Affordable and low-maintenance, vinyl siding serves as a practical alternative, while decorative exterior wall panels offer enhanced aesthetics, design versatility, and modern appeal for homeowners seeking both functionality and style.

- Wood Siding: Offering a natural, timeless appeal, wood siding requires more maintenance but provides excellent insulation.

- Fiber Cement Siding: A durable option that mimics the look of wood without the maintenance concerns.

- Brick Veneer: Provides a classic, sturdy appearance and excellent durability.

Advantages of Traditional Siding

Traditional siding options have stood the test of time for several reasons:

- Familiarity: Many homeowners and contractors are comfortable with the installation and maintenance of traditional siding.

- Cost-Effectiveness: Some traditional siding options, like vinyl, can be more budget-friendly upfront.

- Versatility: Traditional siding comes in various styles and colors to suit different architectural designs.

- Proven Track Record: With decades of use, the long-term performance of traditional siding is well-documented.

Limitations of Traditional Siding

Despite its advantages, traditional siding has some drawbacks:

- Limited Design Options: Compared to decorative exterior wall panels, traditional siding offers fewer possibilities for unique, modern designs.

- Maintenance Requirements: Some types, particularly wood siding, require regular maintenance to maintain - appearance and functionality.

- Environmental Concerns: Certain traditional siding materials may not be as eco-friendly as modern alternatives.

Making the Choice: Factors to Consider

Aesthetic Goals

Consider the overall look you want to achieve for your building. Decorative exterior wall panels offer a wider range of modern, sophisticated designs, while traditional siding provides a more classic, familiar appearance.

Durability and Maintenance

Assess your willingness and ability to perform regular maintenance. Decorative exterior wall panels, like those from Sandong Building Materials, often require less upkeep than traditional siding options, particularly wood siding.

Energy Efficiency

Many decorative exterior wall panels are designed with energy efficiency in mind, offering superior insulation properties. This can lead to long-term cost savings on heating and cooling.

Installation Complexity

Consider the ease of installation. Decorative exterior wall panels are often designed for quick and easy installation, which can reduce labor costs and project timelines.

Long-Term Value

While decorative exterior wall panels may have a higher upfront cost, their durability, low maintenance requirements, and energy efficiency can provide greater long-term value compared to some traditional siding options.

Conclusion

Conclusion

The choice between decorative exterior wall panels and traditional siding ultimately depends on your specific needs, aesthetic preferences, and long-term goals for your building. Decorative exterior wall panels offer unparalleled design flexibility, durability, and low maintenance, making them an excellent choice for those seeking a modern, sophisticated look with minimal upkeep. Traditional siding, on the other hand, provides a classic appearance and may be more budget-friendly upfront.

As you weigh your options, consider the innovative solutions offered by decorative exterior wall panels manufacturers like Sandong Building Materials. Their metal siding wall panels combine aesthetic appeal with practical benefits, offering a perfect blend of form and function for your exterior cladding needs.

Ready to explore the possibilities of decorative exterior wall panels for your next project? Contact Sandong Building Materials at info@sdqsc.com to learn more about their cutting-edge exterior cladding solutions and how they can transform your building's facade.

FAQ

Are decorative exterior wall panels more expensive than traditional siding?

While the initial cost may be higher, decorative panels often provide better long-term value due to their durability and low maintenance requirements.

Can decorative exterior wall panels be used in residential projects?

Absolutely! These panels are versatile and suitable for both residential and commercial applications.

How long do decorative exterior wall panels typically last?

With proper installation and minimal maintenance, high-quality decorative panels can last for decades, often outlasting traditional siding options.

Are decorative exterior wall panels environmentally friendly?

Many modern panels are designed with sustainability in mind, offering energy efficiency and using eco-friendly materials in their production.

References

1.Building Materials Review. (2022). "Trends in Exterior Cladding: A Comprehensive Analysis."

2.Journal of Architectural Engineering. (2023). "Comparative Study of Modern Cladding Systems and Traditional Siding."

3.Energy Efficiency in Buildings. (2021). "Impact of Exterior Cladding Choices on Building Energy Performance."

4.Construction Technology Today. (2023). "Advancements in Decorative Exterior Wall Panel Manufacturing."

5.Architectural Digest. (2022). "Transforming Facades: The Rise of Decorative Exterior Panels in Modern Architecture."

Thermal Performance: A Game-Changing Difference

Thermal Performance: A Game-Changing Difference

FAQs

FAQs

Conclusion

Conclusion.webp)

.webp)

Rapid Installation and Minimal Maintenance

Rapid Installation and Minimal Maintenance

.webp)

Conclusion

Conclusion