Introducing the Composition and Benefits of Polyurethane Sandwich PUF Panels

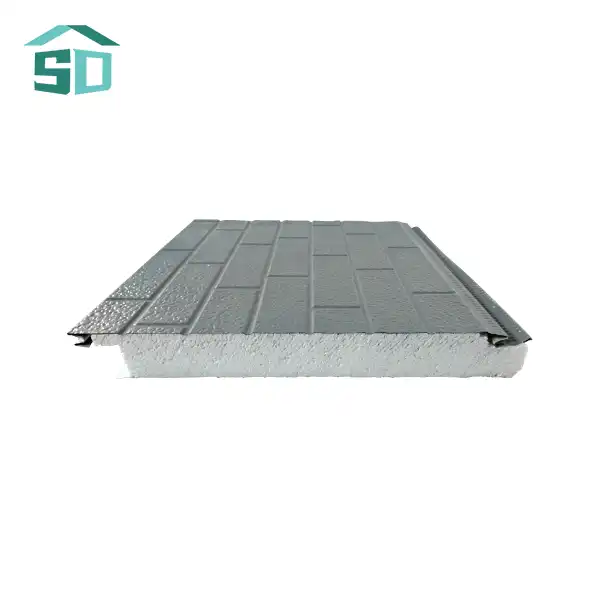

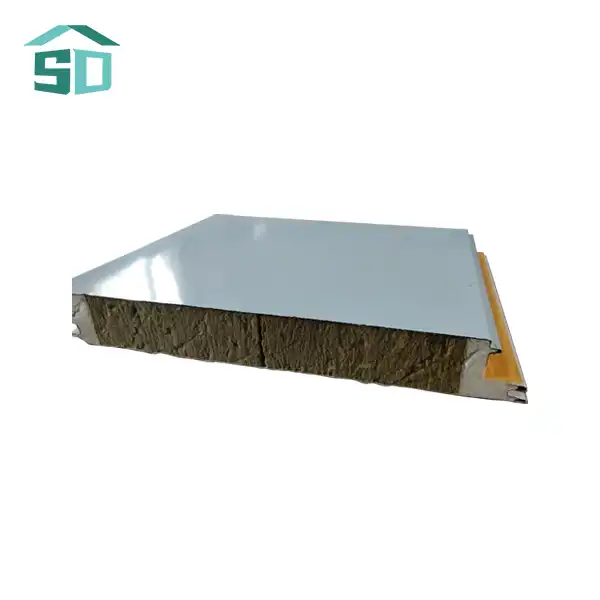

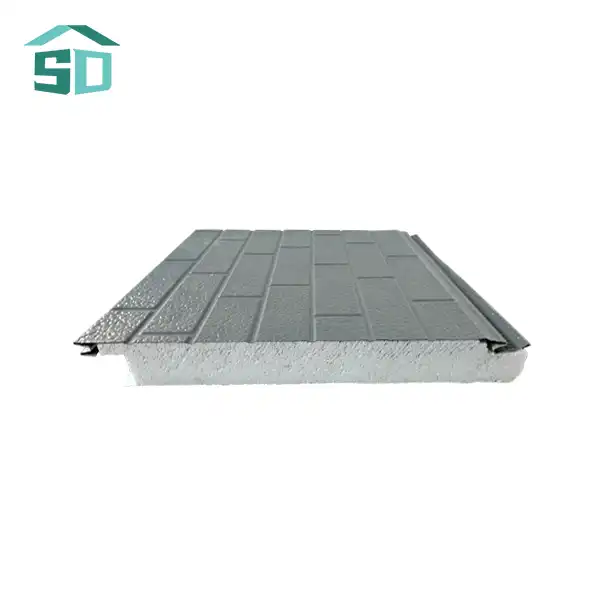

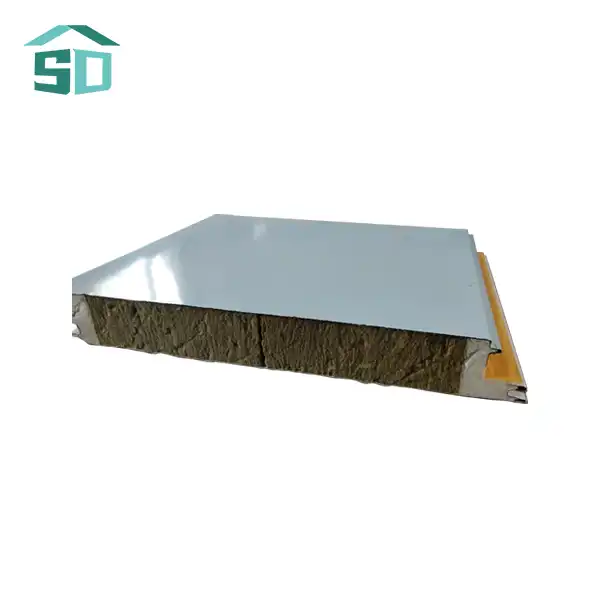

Polyurethane sandwich PUF panels have revolutionized the construction industry with their unique composition and myriad benefits. These panels consist of a polyurethane foam core sandwiched between two layers of metal or other materials, creating a robust and highly insulative building component.

Composition and Structure

The core of polyurethane sandwich PUF panels is made from closed-cell polyurethane foam, which provides exceptional thermal insulation properties. This core is encased between two facing materials, typically steel or aluminum sheets, which offer structural strength and protection against external elements. The thickness of these panels can be customized based on specific project requirements, with interior panels generally measuring around 10mm thick and exterior panels ranging from 16mm to 20mm.

Unparalleled Thermal Performance

One of the standout features of polyurethane sandwich PUF panels is their remarkable thermal insulation capabilities. With a thermal conductivity of just 0.018 W/m.K, these panels significantly reduce heat transfer, leading to substantial energy savings in heating and cooling costs. This low thermal conductivity, coupled with a thermal resistance of 2.09 m²K/W, ensures that buildings maintain ideal temperatures year-round, enhancing comfort and energy efficiency.

Fire and Moisture Resistance

Safety is paramount in construction, and polyurethane sandwich PUF panels excel in this aspect. They meet B1/B2 fire safety standards, offering enhanced fire resistance for peace of mind. Additionally, these panels boast an exceptional waterproof rate of 0.0008, providing superior protection against moisture infiltration and potential water damage.

Structural Integrity and Wind Resistance

Despite their lightweight nature, polyurethane sandwich PUF panels demonstrate impressive structural strength. They can withstand wind pressures of up to 8.0 kPa, ensuring stability even in extreme weather conditions. This resilience makes them ideal for use in areas prone to high winds or severe storms.

Versatility in Design and Application

The adaptability of polyurethane sandwich PUF panels is another key advantage. They can be customized in terms of size, thickness, and finish to meet specific project needs. With exterior widths of 383mm and interior widths of 450mm, these panels offer flexibility in design and installation. The surface material thickness can vary from 0.23mm to 0.27mm, allowing for further customization based on structural requirements.

Implementing Effective Maintenance Strategies for Polyurethane Sandwich PUF Panels

To ensure the longevity and optimal performance of polyurethane sandwich PUF panels, a comprehensive maintenance strategy is essential. Regular upkeep not only preserves the panels' aesthetic appeal but also maintains their structural integrity and insulative properties.

Regular Inspection and Cleaning

Periodic inspections are crucial for identifying potential issues before they escalate. Building managers should conduct visual examinations at least twice a year, paying close attention to panel joints, fasteners, and surface conditions. Any signs of damage, such as dents, scratches, or discoloration, should be promptly addressed.

Cleaning is an integral part of maintenance. Use a mild detergent solution and soft-bristled brush to remove dirt, dust, and other contaminants. Avoid using abrasive materials or harsh chemicals that could damage the panel surface. For stubborn stains, consult the manufacturer's guidelines for appropriate cleaning methods.

Addressing Moisture and Sealant Integrity

Given the exceptional waterproof rate of 0.0008, polyurethane sandwich PUF panels are highly resistant to moisture. However, it's crucial to maintain this integrity over time. Regularly inspect and replace sealants around panel joints and penetrations to prevent water ingress. Pay special attention to areas prone to water accumulation, such as corners and horizontal surfaces.

If moisture infiltration is suspected, use moisture meters to detect any internal dampness. Address any issues immediately to prevent potential damage to the foam core or metal facings.

Structural Maintenance and Repair

While polyurethane sandwich PUF panels are known for their durability, with a compressive strength of 52.7 kPa, they may occasionally require repairs. Small dents or scratches can often be addressed with touch-up paint or filler compounds designed for metal surfaces. For more significant damage, consult with the manufacturer or a qualified professional to determine the best course of action.

Regularly check the fasteners and connection points to ensure they remain secure. Loose or corroded fasteners should be replaced promptly to maintain the panels' wind resistance capabilities of up to 8.0 kPa.

Maximizing Energy Efficiency and Longevity of Polyurethane Sandwich PUF Panels

The exceptional thermal properties of polyurethane sandwich PUF panels, including their low thermal conductivity of 0.018 W/m.K, make them an ideal choice for energy-efficient buildings. However, maintaining this efficiency over time requires attention to detail and proactive measures.

Preserving Insulation Integrity

The insulative properties of polyurethane sandwich PUF panels are largely dependent on the integrity of the foam core. Any damage that compromises this core can significantly reduce the panels' thermal resistance of 2.09 m²K/W. Regular thermographic inspections can help identify areas of heat loss, allowing for targeted repairs or replacements as necessary.

Ensure that the building's HVAC system is properly balanced to avoid putting undue stress on the panels. Excessive pressure differences between the interior and exterior can lead to air infiltration and reduced insulation effectiveness.

UV Protection and Surface Maintenance

While the metal facings of polyurethane sandwich PUF panels offer good resistance to UV radiation, prolonged exposure can lead to fading or degradation over time. Consider applying UV-resistant coatings to exterior panels to extend their lifespan and maintain their aesthetic appeal.

Regular surface treatments, such as waxing or polishing, can help preserve the panels' appearance and provide an additional layer of protection against environmental factors. Always use products specifically designed for use on metal surfaces and follow the manufacturer's recommendations.

Adapting Maintenance for Specific Applications

The versatility of polyurethane sandwich PUF panels means they are used in a wide range of applications, from residential complexes to industrial facilities. Tailor your maintenance approach based on the specific environmental conditions and usage patterns of your building.

For example, panels used in coastal areas may require more frequent inspections and specialized treatments to protect against salt corrosion. In industrial settings, where panels may be exposed to chemical fumes or abrasive particles, additional protective measures and more frequent cleaning may be necessary.

By implementing these targeted maintenance strategies, building owners and managers can ensure their polyurethane sandwich PUF panels continue to provide optimal performance, energy efficiency, and aesthetic appeal for years to come.

Conclusion

Polyurethane sandwich PUF panels represent a significant advancement in building materials, offering a unique combination of thermal efficiency, structural integrity, and design flexibility. By implementing a comprehensive maintenance strategy that includes regular inspections, prompt repairs, and proactive protective measures, building owners can maximize the lifespan and performance of these innovative panels.

The key to long-lasting polyurethane sandwich PUF panels lies in understanding their unique properties and addressing potential issues before they escalate. From preserving their exceptional thermal insulation to maintaining their aesthetic appeal, proper maintenance ensures these panels continue to deliver value throughout their lifecycle.

For more information on polyurethane sandwich PUF panels and expert guidance on their maintenance and application, please contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of specialists is dedicated to providing unparalleled service and support for all your exterior cladding and facade solution needs.