The Science Behind Insulated Steel Siding Panels

Composition and Structure

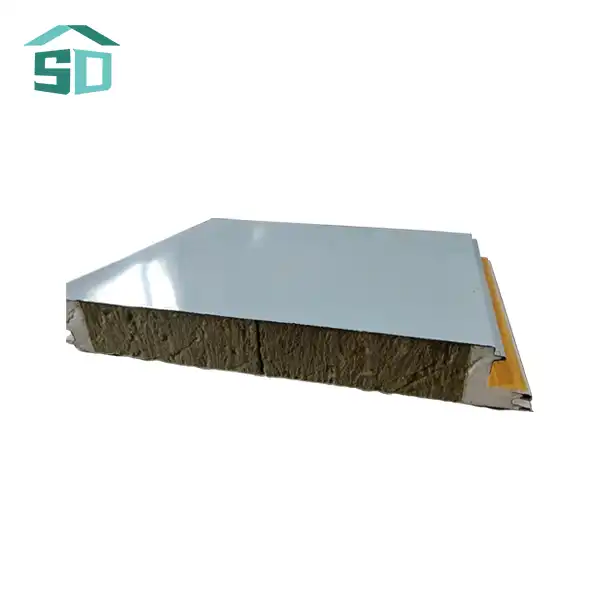

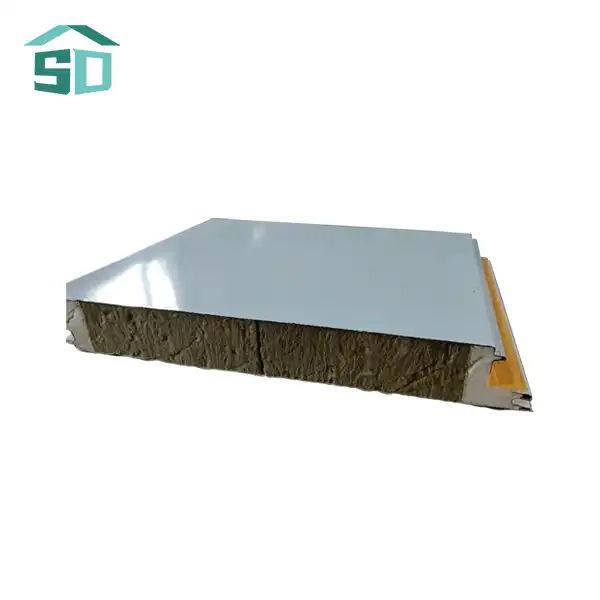

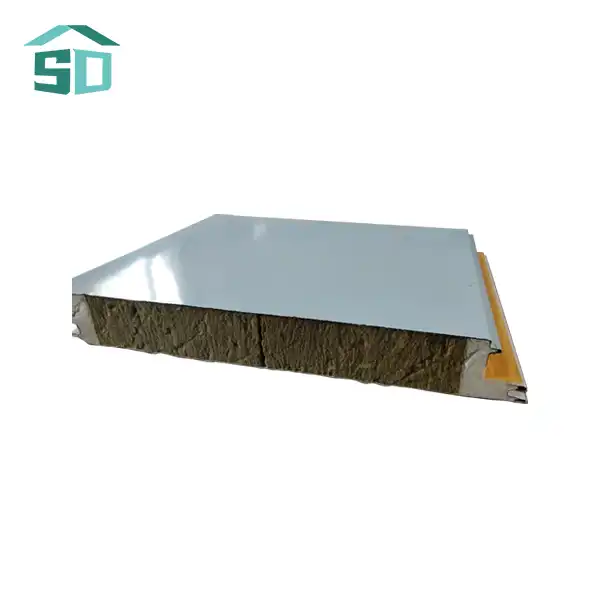

Insulated steel siding panels are engineered marvels that combine the strength of steel with advanced insulation materials. The panels typically consist of two layers of steel encasing a core of high-performance insulation. This insulation core is usually made of materials like polyurethane, polystyrene, or rock wool, each offering unique thermal properties.

The steel layers provide exceptional durability and weather resistance, while the insulation core creates a formidable barrier against heat transfer. This sandwich-like structure is what gives insulated steel siding panels their superior thermal performance.

R-Value: The Measure of Insulation Effectiveness

When evaluating insulated steel siding panels, one crucial factor to consider is the R-value. This metric quantifies the panel's resistance to heat flow, with higher values indicating better insulation properties. The R-value of insulated steel siding panels can vary depending on factors such as the thickness of the panel and the type of insulation used.

Typically, these panels offer R-values ranging from R-7 to R-30, significantly higher than traditional siding materials. This enhanced insulation capacity translates directly into improved energy efficiency for buildings.

Steel Gauge and Its Impact

The steel gauge used in insulated steel siding panels also plays a vital role in their overall performance. A lower gauge number indicates thicker steel, which contributes to increased durability and structural integrity. Most insulated steel siding panels use steel gauges between 22 and 29, striking a balance between strength and weight.

The thickness of the steel not only affects the panel's durability but also influences its thermal performance. Thicker steel can provide additional insulation, further enhancing the panel's energy-saving capabilities.

Benefits Beyond Energy Savings

Durability and Low Maintenance

Insulated steel siding panels are renowned for their exceptional durability. Unlike traditional siding materials that may warp, rot, or fade over time, steel panels maintain their integrity for decades. This longevity translates into reduced maintenance costs and fewer replacements, contributing to long-term cost savings.

The steel exterior is resistant to impacts, pests, and extreme weather conditions, ensuring that the panels continue to perform optimally year after year. This durability not only protects the building but also maintains the insulation's effectiveness over time.

Enhanced Comfort and Noise Reduction

Beyond energy savings, insulated steel siding panels significantly improve indoor comfort. By maintaining consistent temperatures and reducing thermal bridging, these panels eliminate cold spots and drafts, creating a more comfortable living or working environment.

An often-overlooked benefit is the panels' sound reduction properties. The insulation core acts as an acoustic barrier, dampening external noises and creating a quieter interior space. This feature is particularly valuable in urban areas or locations near busy roads.

Fire Resistance and Safety

Safety is paramount in building design, and insulated steel siding panels contribute significantly to fire resistance. Many of these panels come with Class A, B, or C fire ratings, indicating their ability to withstand fire exposure. The steel exterior and fire-resistant insulation materials work together to slow the spread of flames, providing valuable time in the event of a fire emergency.

Customization and Aesthetic Appeal

Design Versatility

Insulated steel siding panels offer remarkable design flexibility, catering to a wide range of architectural styles. Available in various thicknesses (typically 2", 3", and 4") and customizable widths up to 48", these panels can be tailored to suit specific project requirements. The panels come in a diverse array of colors and finishes, allowing architects and homeowners to achieve their desired aesthetic. From sleek, modern looks to more traditional appearances, insulated steel siding panels can complement any building design.

Surface Treatments and Finishes

The versatility of insulated steel siding panels extends to their surface treatments. Options include pre-painted, anodized, or coated finishes, each offering unique benefits in terms of appearance and durability. These treatments not only enhance the panels' aesthetic appeal but also provide additional protection against weathering and corrosion.

Long-Term Value

Investing in insulated steel siding panels offers long-term value that extends beyond immediate energy savings. With warranties typically ranging from 10 to 20 years, depending on the application, property owners can have confidence in the longevity of their investment. The combination of energy efficiency, durability, and low maintenance requirements makes insulated steel siding panels a cost-effective solution over the life of the building. As energy costs continue to rise, the savings provided by these panels will only become more significant.

Conclusion

Insulated steel siding panels represent a significant advancement in building envelope technology, offering a powerful solution for maximizing energy savings. By combining superior insulation properties with durability, aesthetic versatility, and additional benefits like noise reduction and fire resistance, these panels provide a comprehensive approach to improving building performance.

As we continue to seek ways to reduce our environmental impact and optimize energy usage, insulated steel siding panels stand out as a smart choice for both new construction and renovation projects. Their ability to enhance energy efficiency while providing long-lasting protection and aesthetic appeal makes them an invaluable asset in modern construction.

For those looking to explore the potential of insulated steel siding panels for their projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, including insulated steel siding panels, please contact us at info@sdqsc.com. Let us help you maximize your building's energy savings and overall performance with our innovative solutions.