The Anatomy of Insulated Sandwich Wall Panels: A Closer Look

Insulated sandwich wall panels represent a revolutionary advancement in building technology, offering a perfect blend of form and function. These panels are meticulously engineered to provide exceptional thermal insulation, structural integrity, and aesthetic appeal. Let's delve into the intricate composition of these versatile panels:

Core Components and Materials

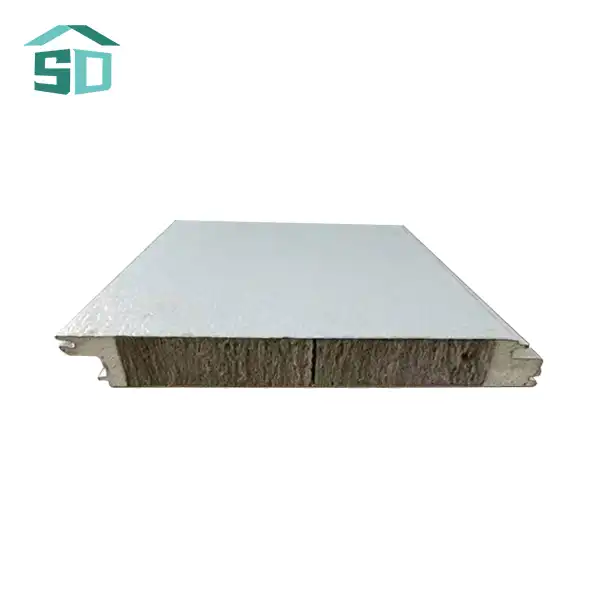

At the heart of insulated sandwich wall panels lies a high-performance insulating core. This core is typically composed of materials such as polyurethane foam, expanded polystyrene, or mineral wool. The choice of core material significantly influences the panel's thermal properties, fire resistance, and overall performance. For instance, polyurethane foam cores offer superior thermal insulation with a thermal conductivity as low as 0.018 W/m.K, ensuring minimal heat transfer and maximizing energy efficiency.

Encasing this insulating core are two robust outer layers, often made of steel or aluminum. These exterior skins not only provide structural strength but also serve as a protective barrier against environmental elements. The thickness of these surface materials can vary, typically ranging from 0.23mm to 0.27mm, depending on the specific requirements of the project.

Dimensional Flexibility and Customization

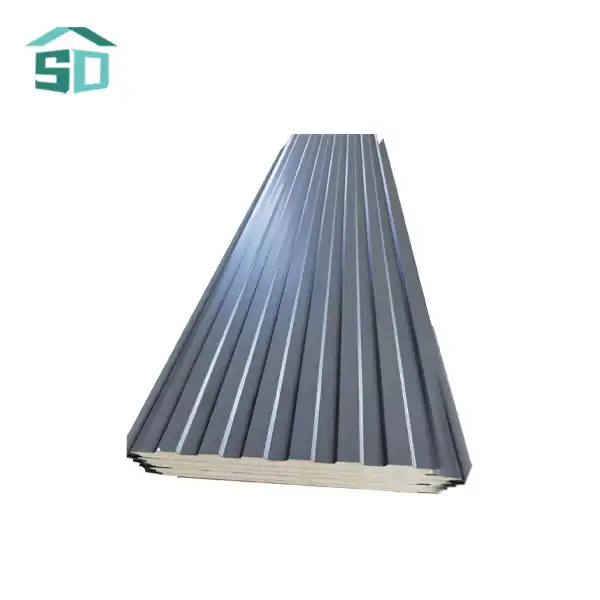

One of the key advantages of insulated sandwich wall panels is their dimensional flexibility. Manufacturers like Weifang Sandong Building Materials Co., Ltd. offer customizable lengths to suit various architectural designs. The thickness of these panels can be tailored to meet specific insulation needs, with interior panels often measuring around 10mm thick, while exterior panels can range from 16mm to 20mm. The width of these panels is also adaptable, with exterior panels typically measuring 383mm wide and interior panels extending to 450mm.

Performance Metrics and Ratings

Insulated sandwich wall panels boast impressive performance metrics that underscore their efficacy in modern construction. With a fire-protection rating of B1/B2, these panels offer substantial resistance to fire propagation, enhancing building safety. Their waterproof rate of 0.0008 ensures excellent protection against moisture ingress, while a wind resistance of 8.0 kPa demonstrates their ability to withstand severe weather conditions.

The thermal resistance of these panels, measured at 2.09 m²K/W, showcases their superior insulating properties. This high thermal resistance translates to significant energy savings in heating and cooling costs. Additionally, with a compressive strength of 52.7 kPa, these panels provide robust structural support, making them suitable for a wide range of construction applications.

Installation and Application: Maximizing the Potential of Insulated Sandwich Wall Panels

The efficacy of insulated sandwich wall panels extends beyond their inherent properties; proper installation and strategic application play pivotal roles in maximizing their potential. Let's explore the installation process and the diverse applications of these versatile building components:

Streamlined Installation Process

One of the most compelling advantages of insulated sandwich wall panels is their ease of installation. The process is designed to be straightforward and efficient, allowing for rapid construction without compromising on quality. Here's a closer look at the installation steps:

1.Preparation: Before installation begins, it's crucial to ensure that the surface is clean, dry, and free from debris. This preparatory step is fundamental in achieving a secure and long-lasting installation.

2.Layout Planning: Careful planning of the panel arrangement is essential. This step involves considering the building design, ensuring optimal coverage, and minimizing waste.

3.Fastening: Using appropriate fasteners, the panels are securely attached to the building structure. The fastening method may vary depending on the specific panel type and building requirements, but the goal is always to ensure a tight, secure fit.

4.Sealing: To maintain the panel's excellent insulation properties and prevent air and water ingress, proper sealing is crucial. Sealants are applied at panel joints and around openings.

5.Finishing: The final step involves applying any desired surface treatments or finishes to enhance the aesthetic appeal or provide additional protection.

Versatile Applications Across Various Sectors

The versatility of insulated sandwich wall panels makes them an ideal choice for a wide range of construction projects. Their applications span across various sectors, including:

- Residential Complexes: From multi-story apartments to single-family homes, these panels provide excellent insulation and aesthetic appeal.

- Commercial Buildings: Offices, retail spaces, and warehouses benefit from the panels' energy efficiency and rapid installation.

- Industrial Facilities: The durability and insulation properties of these panels make them ideal for factories and storage facilities.

- Agricultural Structures: Barns, greenhouses, and other agricultural buildings can maintain optimal internal conditions with these panels.

- Educational Institutions: Schools and universities can create comfortable learning environments while reducing energy costs.

- Healthcare Facilities: Hospitals and clinics can maintain strict temperature control and hygiene standards with these panels.

Customization for Aesthetic and Functional Requirements

Insulated sandwich wall panels offer a high degree of customization, allowing architects and builders to meet both aesthetic and functional requirements. The panels can be manufactured in a variety of colors and patterns, enabling them to complement or enhance any architectural style. This customization extends to the functional aspects as well, with options for different insulation thicknesses, fire ratings, and surface finishes to meet specific project needs.

Environmental Impact and Sustainability: The Green Advantage of Insulated Sandwich Wall Panels

In an era where environmental consciousness is paramount, insulated sandwich wall panels emerge as a beacon of sustainability in the construction industry. Their design and composition contribute significantly to energy efficiency and resource conservation, aligning with global efforts to reduce carbon footprints and promote green building practices.

Energy Efficiency and Thermal Performance

The superior insulation properties of these panels play a crucial role in enhancing the energy efficiency of buildings. With a thermal conductivity of just 0.018 W/m.K, these panels significantly reduce heat transfer between the interior and exterior of a building. This exceptional thermal performance translates to reduced energy consumption for heating and cooling, leading to lower greenhouse gas emissions and decreased operational costs over the building's lifecycle.

Durability and Longevity

The durability of insulated sandwich wall panels contributes to their sustainability profile. These panels are designed to withstand harsh environmental conditions, including extreme temperatures, high winds, and moisture exposure. Their corrosion-resistant properties ensure a long service life, reducing the need for frequent replacements or repairs. This longevity not only conserves resources but also minimizes the environmental impact associated with manufacturing and transporting replacement materials.

Recyclability and Waste Reduction

Many components of insulated sandwich wall panels are recyclable, particularly the metal outer layers. At the end of their service life, these materials can be reclaimed and repurposed, reducing the demand for virgin resources. Additionally, the precise manufacturing process and ease of installation result in minimal on-site waste, further contributing to resource conservation and waste reduction in construction projects.

Contribution to Green Building Certifications

The use of insulated sandwich wall panels can contribute significantly to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design). Their energy efficiency, recycled content, and potential for local sourcing align with many of the criteria set forth by these certification programs. This not only enhances the environmental profile of the building but can also lead to tangible benefits such as tax incentives and increased property value.

Conclusion

Insulated sandwich wall panels represent a significant advancement in building technology, offering a perfect balance of performance, versatility, and sustainability. Their superior insulation properties, coupled with ease of installation and customization options, make them an ideal choice for a wide range of construction projects.

As the construction industry continues to evolve towards more sustainable practices, these panels stand out as a solution that meets both current needs and future environmental challenges. For those seeking to leverage the benefits of insulated sandwich wall panels in their projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, please contact us at info@sdqsc.com.