Enhancing Energy Efficiency with Aluminum Foam Sandwich Panels

In the realm of industrial construction, energy efficiency has become a paramount concern. Aluminum foam sandwich panels have emerged as a game-changer in this aspect, offering unparalleled insulation properties that significantly reduce energy consumption in industrial buildings.

Thermal Insulation Excellence

The unique structure of aluminum foam sandwich panels contributes to their exceptional thermal insulation capabilities. The foam core, typically made of closed-cell aluminum foam, acts as a formidable barrier against heat transfer. This results in maintaining stable indoor temperatures, reducing the load on HVAC systems, and consequently, lowering energy costs for industrial facilities.

Year-Round Climate Control

Industrial buildings often face extreme temperature fluctuations, which can affect productivity and equipment performance. Aluminum foam sandwich panels excel in providing year-round climate control. In summer, they reflect heat and prevent excessive warmth from penetrating the building, while in winter, they retain interior heat, ensuring a comfortable working environment regardless of external conditions.

Acoustic Insulation Benefits

Beyond thermal insulation, aluminum foam sandwich panels also offer impressive sound dampening properties. This is particularly beneficial for industrial settings where noise reduction is crucial. The porous structure of the aluminum foam core absorbs sound waves, creating a quieter indoor environment. This feature is especially valuable in manufacturing plants or facilities located near residential areas, helping to minimize noise pollution and improve working conditions.

Structural Integrity and Safety Features of Aluminum Foam Sandwich Panels

When it comes to industrial buildings, structural integrity and safety are non-negotiable factors. Aluminum foam sandwich panels have proven to be exceptional in meeting these critical requirements, offering a combination of strength, durability, and fire resistance.

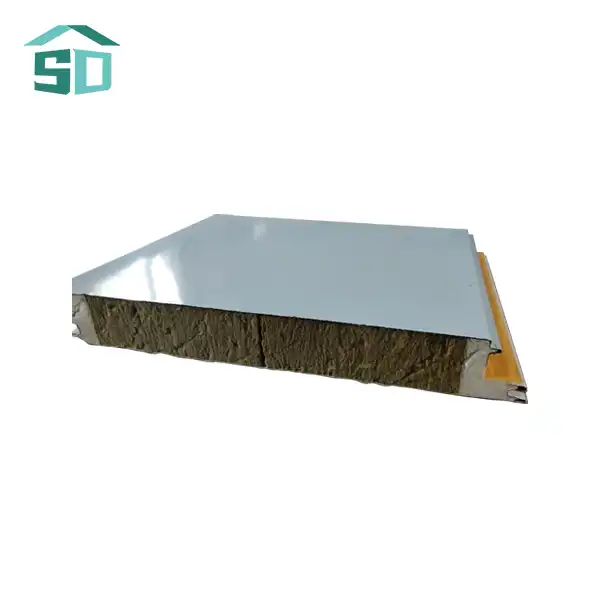

Lightweight Yet Robust Construction

One of the most striking features of aluminum foam sandwich panels is their ability to provide substantial strength while maintaining a lightweight profile. This characteristic makes them ideal for industrial applications where weight reduction is crucial without compromising on structural integrity. The unique composition of these panels, with dense aluminum sheets encasing a foam core, results in a material that can withstand significant loads and stresses typically encountered in industrial environments.

Fire Resistance and Safety

Safety is paramount in industrial settings, and aluminum foam sandwich panels rise to the challenge with their impressive fire-resistant properties. These panels are engineered to meet stringent fire safety standards, often achieving Class A fire ratings. The aluminum foam core acts as an effective fire barrier, slowing the spread of flames and providing valuable time for evacuation in case of emergencies. This fire-resistant quality is particularly crucial in industries dealing with flammable materials or high-temperature processes.

Corrosion and Weather Resistance

Industrial buildings are often exposed to harsh environmental conditions, including corrosive atmospheres and extreme weather. Aluminum foam sandwich panels exhibit excellent resistance to corrosion, ensuring long-term durability even in challenging industrial environments. Their weather-resistant properties also make them suitable for both interior and exterior applications, protecting the building from rain, snow, UV radiation, and other environmental factors that could compromise the structure's integrity over time.

Versatility and Cost-Effectiveness in Industrial Applications

The adaptability and economic benefits of aluminum foam sandwich panels make them an attractive option for a wide range of industrial applications. Their versatility extends from structural components to aesthetic enhancements, offering comprehensive solutions for modern industrial construction.

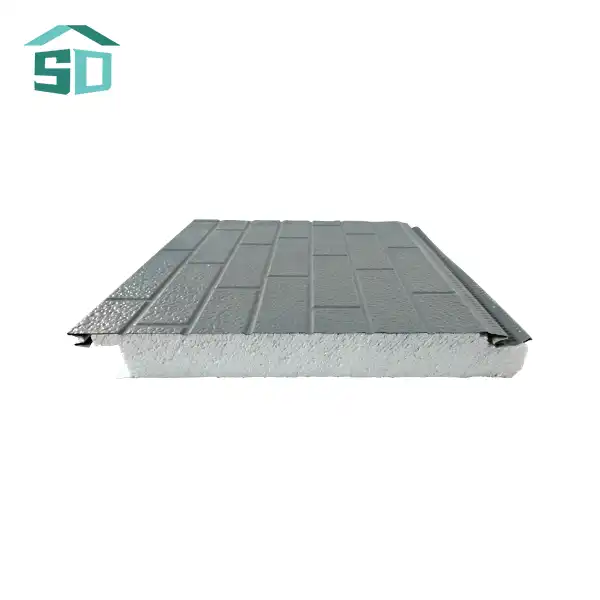

Customizable Design Options

Aluminum foam sandwich panels offer remarkable flexibility in design, catering to diverse architectural and functional requirements of industrial buildings. These panels can be customized in terms of size, thickness, and surface finish, allowing architects and engineers to create unique and efficient structures. The ability to tailor these panels to specific project needs ensures optimal performance and aesthetics, whether for a sleek, modern manufacturing facility or a robust warehouse complex.

Rapid Installation and Reduced Labor Costs

One of the significant advantages of using aluminum foam sandwich panels in industrial construction is the speed and ease of installation. These panels are designed for quick assembly, significantly reducing construction time compared to traditional building methods. The lightweight nature of the panels facilitates easier handling and transportation, further streamlining the construction process. This efficiency translates to lower labor costs and faster project completion times, which is particularly beneficial in the industrial sector where time is often of the essence.

Long-Term Cost Benefits

While the initial investment in aluminum foam sandwich panels might be higher than some traditional materials, the long-term cost benefits are substantial. The durability and low maintenance requirements of these panels result in reduced lifecycle costs. Their energy-efficient properties contribute to lower operational expenses over time, making them a cost-effective choice for industrial buildings. Additionally, the potential for recycling and reuse aligns with sustainable building practices, potentially offering further economic benefits in the form of tax incentives or compliance with environmental regulations.

Conclusion

Aluminum foam sandwich panels have emerged as a revolutionary material in industrial construction, offering a unique combination of strength, insulation, and versatility. Their applications in industrial buildings span from enhancing energy efficiency and ensuring structural integrity to providing cost-effective and customizable solutions. As the construction industry continues to evolve, these panels stand out as a forward-thinking choice for modern industrial facilities. Their ability to meet diverse needs while adhering to safety and sustainability standards makes them an invaluable asset in the realm of industrial architecture and engineering.

For those seeking to leverage the benefits of aluminum foam sandwich panels in their industrial projects, partnering with a reputable aluminum foam sandwich panels supplier is crucial. At Weifang Sandong Building Materials Co., Ltd., we offer high-quality aluminum foam sandwich panels tailored to meet the specific requirements of your industrial building projects. Our expertise in exterior cladding and facade solutions ensures that you receive products that not only meet but exceed industry standards. To explore how our aluminum foam sandwich panels can transform your industrial building, contact us at info@sdqsc.com.

FAQs

What makes aluminum foam sandwich panels suitable for industrial buildings?

These panels offer excellent thermal insulation, fire resistance, and structural strength while being lightweight, making them ideal for various industrial applications.

Can aluminum foam sandwich panels be customized for specific industrial needs?

Yes, they can be customized in terms of size, thickness, and surface finish to meet specific architectural and functional requirements.

How do aluminum foam sandwich panels contribute to energy efficiency in industrial settings?

Their superior insulation properties help maintain stable indoor temperatures, reducing HVAC loads and energy costs.

Are aluminum foam sandwich panels environmentally friendly?

Yes, they are recyclable and contribute to sustainable building practices, potentially offering economic benefits through compliance with environmental regulations.

References

1.Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

2.Ashby, M. F., Evans, A., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

3.Lefebvre, L. P., Banhart, J., & Dunand, D. C. (2008). Porous Metals and Metallic Foams: Current Status and Recent Developments. Advanced Engineering Materials, 10(9), 775-787.

4.Wadley, H. N. G. (2002). Cellular Metals Manufacturing. Advanced Engineering Materials, 4(10), 726-733.

5.Baumeister, J., Banhart, J., & Weber, M. (1997). Aluminium foams for transport industry. Materials & Design, 18(4-6), 217-220.