The Rise of Foam Exterior Wall Cladding: A Game-Changer in Building Insulation

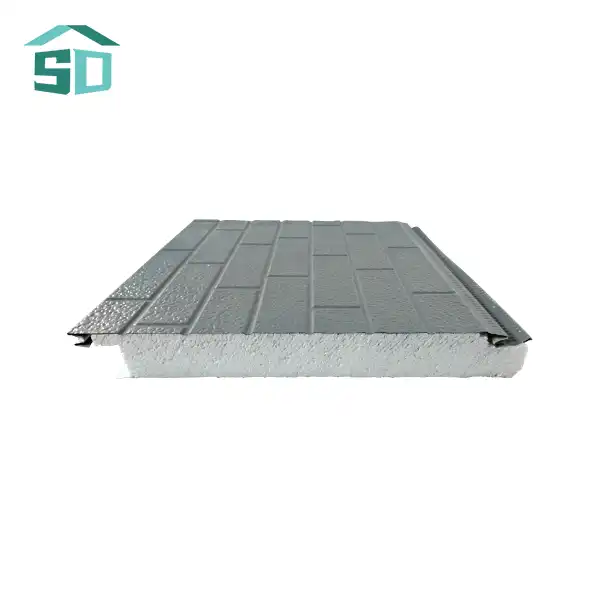

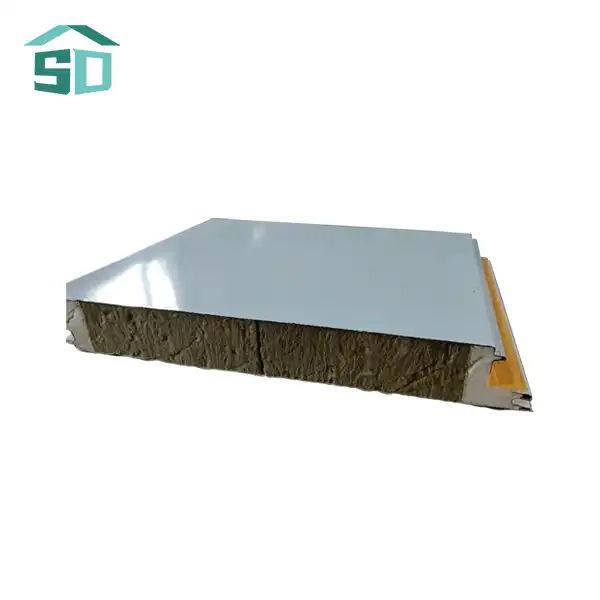

Foam exterior wall cladding has revolutionized the construction industry, offering a myriad of benefits that traditional siding materials struggle to match. This innovative solution combines insulation and protective properties in a single product, addressing the growing demand for energy-efficient building materials. The exceptional thermal performance of foam cladding stems from its closed-cell structure, which effectively traps air and minimizes heat transfer.

One of the standout features of foam cladding is its remarkable R-value, a measure of thermal resistance. With a thermal conductivity of just 0.018W/m.k and a thermal resistance of 2.09m2k/w, foam cladding significantly outperforms many traditional siding materials. This translates to substantial energy savings for homeowners and businesses alike, as heating and cooling costs are dramatically reduced.

Moreover, foam cladding's versatility extends beyond its insulation properties. Available in a wide range of colors, textures, and finishes, it offers architects and designers unprecedented freedom to create visually striking exteriors. The ability to mimic the appearance of traditional materials like wood, stone, or brick allows for seamless integration with existing architectural styles while providing superior performance.

Durability and Weather Resistance

Foam exterior wall cladding boasts impressive durability and weather resistance, making it an ideal choice for diverse climatic conditions. With a wind resistance of 8.0 Kpa, it can withstand severe weather events without compromising its structural integrity. The material's inherent resistance to moisture, rot, and corrosion ensures longevity, even in challenging environments.

Additionally, foam cladding's fire-protection rating of B1/B2 provides an extra layer of safety for buildings. This flame-retardant property is particularly valuable in areas prone to wildfires or in structures where fire safety is a top priority. The cladding's ability to slow the spread of flames can potentially save lives and protect property in the event of a fire.

Environmental Impact and Sustainability

As the construction industry increasingly focuses on sustainable practices, foam exterior wall cladding has emerged as an eco-conscious choice. Made from environmentally friendly materials, it supports green building initiatives without sacrificing performance. The energy-saving properties of foam cladding contribute to reduced carbon footprints, aligning with global efforts to combat climate change.

Furthermore, the lightweight nature of foam cladding reduces transportation costs and associated emissions. Its long lifespan and minimal maintenance requirements also translate to fewer replacements over time, further minimizing its environmental impact. As sustainability becomes a key consideration in construction projects, foam cladding stands out as a responsible and forward-thinking option.

Installation and Maintenance: Simplifying the Building Process

One of the most appealing aspects of foam exterior wall cladding is its ease of installation. The lightweight nature of the material, combined with its customizable dimensions, makes it significantly easier to handle and install compared to traditional siding options. This translates to reduced labor costs and faster project completion times, a crucial factor in today's fast-paced construction industry.

Foam cladding panels can be easily cut to size on-site, allowing for precise fitting around windows, doors, and other architectural features. The installation process typically involves the following steps:

1.Surface preparation: Ensuring the wall surface is clean, dry, and free from debris.

2.Panel cutting: Using a saw to cut panels to the desired size, ensuring accurate measurements.

3.Adhesive application: Applying a suitable adhesive to attach the panels to the wall.

4.Panel securing: Fastening panels using screws or mechanical fasteners for added stability.

5.Finishing: Sealing joints with appropriate sealants to enhance insulation and aesthetics.

The straightforward installation process not only saves time but also reduces the likelihood of errors, ensuring a high-quality finish. Additionally, foam cladding's low maintenance requirements further enhance its appeal. Unlike some traditional siding materials that may require frequent painting or sealing, foam cladding retains its appearance and performance with minimal upkeep.

Versatility in Application

Foam exterior wall cladding's versatility makes it suitable for a wide range of applications across various sectors. In residential construction, it enhances both the curb appeal and energy efficiency of homes. Commercial spaces benefit from its professional appearance and superior insulation properties, potentially leading to significant energy cost savings.

Industrial facilities find foam cladding particularly valuable for its thermal insulation and soundproofing capabilities. The material's ability to maintain stable internal temperatures can be crucial in environments where temperature control is essential. Even in the transportation sector, foam cladding has found applications in vehicles and vessels, providing insulation and aesthetic enhancement.

Customization and Aesthetic Appeal

One of the most significant advantages of foam exterior wall cladding is its unparalleled customization options. Available in a diverse range of colors, textures, and patterns, it allows architects and designers to bring their creative visions to life. The ability to tailor the appearance of foam cladding to match specific project requirements or architectural styles provides a level of flexibility that many traditional siding materials cannot match.

Moreover, the surface materials of foam cladding, ranging from 0.23mm to 0.27mm in thickness, can be treated to resist UV rays, preventing fading and degradation over time. This UV stability ensures that the aesthetic appeal of the cladding remains intact for years, maintaining the building's appearance with minimal intervention.

Technical Specifications and Performance Metrics

To fully appreciate the capabilities of foam exterior wall cladding, it's essential to delve into its technical specifications and performance metrics. These quantifiable attributes provide concrete evidence of the material's superiority in various aspects of building protection and energy efficiency.

The thickness of foam cladding panels varies depending on their application, with interior panels typically measuring 10mm thick, while exterior panels range from 16mm to 20mm. This variation in thickness allows for optimal insulation in different parts of a building. The width of exterior panels is standardized at 383mm, while interior panels measure 450mm, providing flexibility in coverage and installation.

One of the most impressive features of foam cladding is its waterproof rate of 0.0008, indicating exceptional resistance to moisture penetration. This property is crucial in protecting the structural integrity of buildings, preventing water damage, and inhibiting the growth of mold and mildew.

The compressive strength of 52.7kpa demonstrates the material's ability to withstand significant pressure without deforming or losing its insulative properties. This robustness ensures that the cladding maintains its performance even under challenging conditions, contributing to its long-term durability.

Energy Efficiency and Cost Savings

The energy-saving potential of foam exterior wall cladding is one of its most compelling attributes. Its exceptional insulation properties, characterized by low thermal conductivity and high thermal resistance, translate to significant reductions in heating and cooling costs. Buildings equipped with foam cladding often experience a noticeable decrease in energy consumption, leading to lower utility bills and a reduced carbon footprint.

The cost-effectiveness of foam cladding extends beyond energy savings. Its durability and low maintenance requirements mean fewer replacements and repairs over the lifetime of the building. When combined with its ease of installation and potential for reducing construction time, foam cladding presents a compelling value proposition for both new construction and renovation projects.

Safety and Compliance

Safety is paramount in construction, and foam exterior wall cladding meets stringent standards in this regard. Its fire-protection rating of B1/B2 indicates a high level of resistance to flame spread, contributing to overall building safety. This rating is particularly important in multi-story buildings or structures where fire safety is a critical concern.

Furthermore, foam cladding's ability to withstand wind loads of up to 8.0 Kpa demonstrates its suitability for use in areas prone to high winds or severe weather events. This resilience ensures that the cladding remains secure and functional even under challenging environmental conditions, providing peace of mind to building owners and occupants.

As building codes and regulations continue to evolve, particularly in relation to energy efficiency and safety, foam cladding's performance metrics position it as a compliant and future-proof solution. Its ability to meet or exceed current standards while offering additional benefits makes it an attractive option for forward-thinking construction projects.

Conclusion

Foam exterior wall cladding has emerged as a formidable contender in the realm of building materials, offering a unique combination of insulation, durability, and aesthetic versatility. Its ability to significantly enhance energy efficiency, withstand diverse weather conditions, and provide customizable design options positions it as a superior alternative to many traditional siding materials. While it may not entirely replace conventional siding in all applications, foam cladding's numerous advantages make it an increasingly popular choice for modern construction and renovation projects.

As the construction industry continues to prioritize energy efficiency, sustainability, and innovative design, foam exterior wall cladding stands poised to play an increasingly significant role. Its blend of performance, aesthetics, and ease of installation addresses many of the challenges faced by architects, builders, and property owners alike. For those seeking a cutting-edge solution that doesn't compromise on quality or appearance, foam cladding offers a compelling answer.

Are you ready to explore the possibilities of foam exterior wall cladding for your next project? Weifang Sandong Building Materials Co., Ltd. is at the forefront of this innovative technology, offering state-of-the-art cladding solutions tailored to your specific needs. From residential complexes to commercial spaces and industrial facilities, our products are designed to enhance both the form and function of your buildings. To learn more about how our foam cladding can transform your project, contact us today at info@sdqsc.com.

FAQ

How long does foam exterior wall cladding typically last?

With proper installation and maintenance, foam cladding can last 20-30 years or more, depending on environmental conditions.

Is foam cladding suitable for all climate types?

Yes, foam cladding is designed to perform well in various climates, from hot and humid to cold and dry environments.

Can foam cladding be painted or refinished?

While foam cladding comes in various colors and finishes, it can also be painted if desired. However, it's important to use compatible paints and follow manufacturer guidelines.

How does foam cladding compare to traditional insulation methods in terms of R-value?

Foam cladding typically offers higher R-values per inch compared to many traditional insulation materials, providing superior thermal efficiency.

References

1.Building Science Corporation. (2021). "Foam Sheathing in Exterior Walls: Design Considerations."

2.Energy.gov. (2022). "Insulation Materials."

3.Journal of Building Engineering. (2020). "Performance assessment of exterior wall insulation systems for buildings."

4.Construction and Building Materials. (2019). "A review on the durability of polymeric foam cladding materials."