The Science Behind PUF Sandwich Panels' Thermal Efficiency

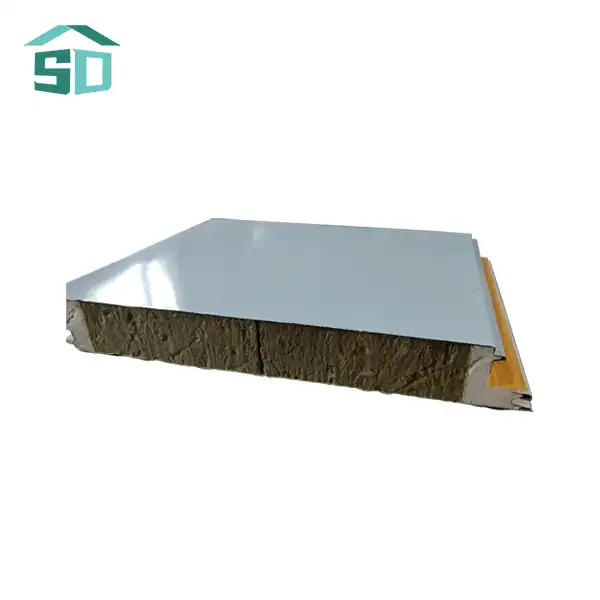

PUF sandwich panels, or Polyurethane Foam sandwich panels, are composite materials engineered for optimal thermal performance. At their core lies a layer of polyurethane foam, sandwiched between two metal sheets – typically steel, aluminum, or stainless steel. This unique construction is the key to their exceptional thermal efficiency.

The polyurethane foam core is a closed-cell structure that effectively traps air, creating a formidable barrier against heat transfer. This structure significantly reduces thermal conductivity, making PUF sandwich panels an ideal choice for maintaining consistent indoor temperatures. The thermal conductivity of PUF panels can be as low as 0.022 W/mK, outperforming many traditional insulation materials.

Moreover, the metal facings of PUF sandwich panels contribute to their thermal performance. These layers reflect radiant heat, further enhancing the panel's ability to maintain a comfortable indoor environment. This combination of insulation and reflection creates a synergistic effect, maximizing thermal efficiency.

Customizable Thickness for Varied Insulation Needs

One of the significant advantages of PUF sandwich panels is their customizable thickness. Panels are available in various thicknesses, typically ranging from 50mm to 100mm. This flexibility allows architects and builders to tailor the insulation properties to specific project requirements. Thicker panels provide higher R-values, making them suitable for extreme climates or applications where superior insulation is paramount.

Comparative Analysis: PUF Sandwich Panels vs. Traditional Insulation Methods

When comparing PUF sandwich panels to traditional insulation methods, the advantages become even more apparent. Let's examine how these innovative panels stack up against conventional options:

PUF Panels vs. Fiberglass Insulation

Fiberglass insulation has been a staple in construction for decades. However, PUF sandwich panels offer several advantages: - Higher R-value per inch: PUF panels provide superior insulation with less thickness. - Moisture resistance: Unlike fiberglass, PUF panels are inherently moisture-resistant, reducing the risk of mold and mildew. - Structural integrity: PUF panels contribute to the building's structural strength, while fiberglass is non-structural. - Air sealing: PUF panels create an effective air barrier, reducing air infiltration and improving overall energy efficiency.

PUF Panels vs. Polystyrene Panels

Expanded polystyrene (EPS) and extruded polystyrene (XPS) panels are common alternatives, but PUF sandwich panels offer distinct benefits: - Higher insulation value: PUF panels generally provide better thermal performance than EPS or XPS. - Durability: PUF panels are more resistant to compression and maintain their insulation properties over time. - Fire resistance: PUF panels can be engineered with fire-retardant properties, offering better safety features. - Versatility: The metal facings of PUF panels allow for a wider range of finishes and applications.

Real-World Applications and Energy Savings

The thermal efficiency of PUF sandwich panels translates into tangible benefits in various applications:

Commercial and Industrial Buildings

In commercial and industrial settings, PUF sandwich panels have proven to be a game-changer. Warehouses, cold storage facilities, and manufacturing plants benefit from the panels' superior insulation properties. By maintaining consistent temperatures, these buildings see significant reductions in energy consumption for heating and cooling. Case studies have shown energy savings of up to 30% in some commercial applications after retrofitting with PUF sandwich panels.

Residential Construction

In the residential sector, PUF sandwich panels are gaining traction for their energy-saving potential. Homes built with these panels experience improved thermal comfort and reduced heating and cooling costs. The panels' ability to create an airtight envelope contributes to better overall energy efficiency. Homeowners have reported noticeable decreases in their utility bills, with some seeing savings of up to 20% on annual energy costs.

Modular and Prefabricated Construction

The lightweight nature and high insulation value of PUF sandwich panels make them ideal for modular and prefabricated construction. These panels allow for rapid assembly while ensuring excellent thermal performance. In modular office buildings and temporary structures, PUF panels have demonstrated their ability to maintain comfortable indoor temperatures even in challenging climates, reducing the reliance on HVAC systems.

The versatility of PUF sandwich panels extends to their aesthetic appeal as well. Available in a range of colors and finishes, these panels can complement any architectural design while providing unparalleled thermal efficiency. This combination of form and function makes PUF sandwich panels a preferred choice for architects and builders looking to create energy-efficient, visually appealing structures.

Conclusion

In the thermal efficiency showdown, PUF sandwich panels have emerged as clear leaders. Their superior insulation properties, versatility, and real-world performance set them apart from traditional methods. As the construction industry continues to prioritize energy efficiency and sustainable building practices, PUF sandwich panels are poised to play an increasingly significant role. Their ability to combine structural integrity with top-tier thermal performance makes them an invaluable asset in modern construction.

Are you ready to elevate your next construction project with the unmatched thermal efficiency of PUF sandwich panels? Weifang Sandong Building Materials Co., Ltd. offers a wide range of customizable PUF sandwich panels to meet your specific needs. From residential to industrial applications, our panels provide the perfect blend of insulation, durability, and aesthetic appeal. Experience the future of building materials and start saving on energy costs today. Contact us at info@sdqsc.com to learn more about how our PUF sandwich panels can transform your construction projects.

FAQ

What makes PUF sandwich panels more thermally efficient than other insulation materials?

PUF sandwich panels excel in thermal efficiency due to their closed-cell polyurethane foam core, which has exceptionally low thermal conductivity. Combined with reflective metal facings, they provide superior insulation performance.

Are PUF sandwich panels suitable for all climate conditions?

Yes, PUF sandwich panels are versatile and can be customized for various climate conditions. Their thickness can be adjusted to meet specific insulation requirements for both hot and cold climates.

How do PUF sandwich panels contribute to energy savings in buildings?

PUF sandwich panels significantly reduce heat transfer, maintaining stable indoor temperatures. This results in lower energy consumption for heating and cooling, leading to substantial energy savings over time.

References

1.Berardi, U., & Naldi, M. (2017). The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy and Buildings, 144, 262-275.

2.Correia-da-Silva, J. J., Mateus, R., & Bragança, L. (2020). Comparative sustainability assessment of alternative external wall systems for buildings. Journal of Building Engineering, 31, 101373.

3.Younes, C., Abi Shdid, C., & Bitsuamlak, G. (2012). Air infiltration through building envelopes: A review. Journal of Building Physics, 35(3), 267-302.

4.Wijewardane, S., & Goswami, D. Y. (2012). A review on surface control of thermal radiation by paints and coatings for new energy applications. Renewable and Sustainable Energy Reviews, 16(4), 1863-1873.

5.Schiavoni, S., D׳Alessandro, F., Bianchi, F., & Asdrubali, F. (2016). Insulation materials for the building sector: A review and comparative analysis. Renewable and Sustainable Energy Reviews, 62, 988-1011.