Understanding the Fire-Resistant Properties of Aluminum Foam Sandwich Panels

The Science Behind Aluminum Foam's Fire Resistance

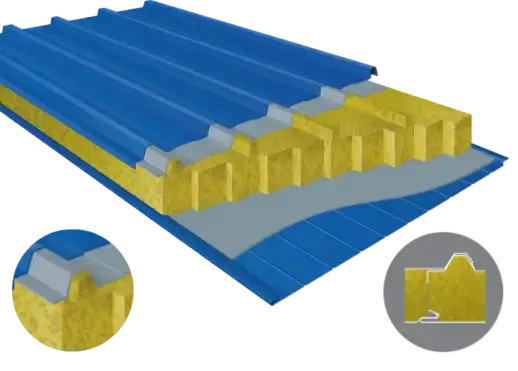

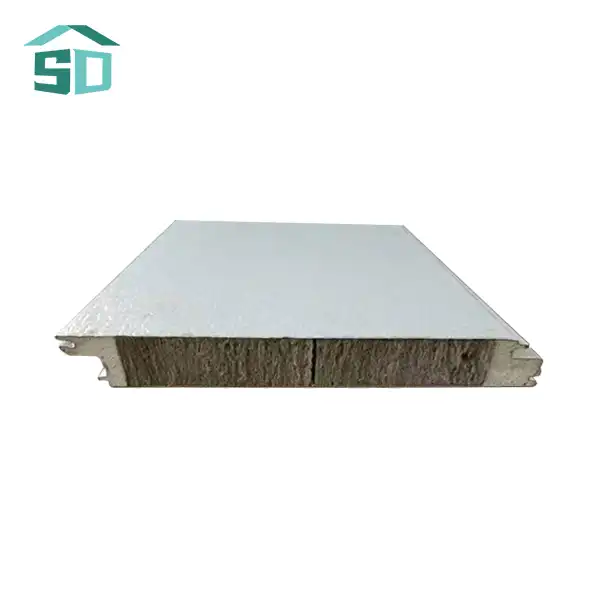

Aluminum foam sandwich panels owe their impressive fire resistance to the unique properties of their core material. The aluminum foam core consists of a network of interconnected cells, creating a structure that's both lightweight and incredibly strong. This cellular structure plays a crucial role in the panel's fire-resistant capabilities.

When exposed to high temperatures, the aluminum foam undergoes a process called endothermic decomposition. This means it absorbs heat energy as it decomposes, effectively slowing down the transfer of heat through the panel. Additionally, the closed-cell structure of the foam limits the amount of oxygen available to fuel the fire, further enhancing its fire-resistant properties.

Fire Rating Classifications and Standards

Fire rating classifications are essential for understanding the performance of building materials in fire conditions. Aluminum foam sandwich panels typically achieve a Class A fire rating, the highest classification available. This rating is determined through rigorous testing procedures outlined by organizations such as ASTM International and the National Fire Protection Association (NFPA).

The most common test for determining fire ratings is the ASTM E84 Surface Burning Characteristics of Building Materials test. This test evaluates two key factors:

- Flame Spread Index: Measures how quickly flames spread across the surface of the material

- Smoke Developed Index: Assesses the amount of smoke produced during combustion

Aluminum foam sandwich panels excel in both these areas, typically achieving low flame spread and smoke development indices, contributing to their Class A fire rating.

Comparative Analysis with Other Building Materials

When compared to other building materials, aluminum foam sandwich panels stand out for their fire-resistant properties. Traditional materials like wood or certain types of plastic composites often fall short in fire performance. Even some metal panels with different core materials may not match the fire resistance of aluminum foam sandwich panels.

For instance, panels with a polyurethane foam core, while offering good insulation, can be more susceptible to fire spread. In contrast, aluminum foam sandwich panels provide an optimal balance of insulation and fire resistance. This makes them a preferred choice for applications where fire safety is a critical concern, such as in high-rise buildings, industrial facilities, or transportation infrastructure.

Applications and Benefits of Fire-Rated Aluminum Foam Sandwich Panels

Enhancing Building Safety with Aluminum Foam Panels

The superior fire performance of aluminum foam sandwich panels significantly enhances building safety. These panels act as an effective barrier against fire spread, potentially buying crucial time for building occupants to evacuate and for firefighters to respond. In high-rise buildings, where rapid vertical fire spread is a major concern, the use of these panels in exterior cladding can greatly improve overall fire safety.

Moreover, the low smoke production characteristic of aluminum foam panels is particularly beneficial in enclosed spaces. In the event of a fire, reduced smoke generation can improve visibility and air quality, potentially saving lives by facilitating easier evacuation and reducing the risk of smoke inhalation.

Versatility in Construction and Design

Beyond their fire-resistant properties, aluminum foam sandwich panels offer remarkable versatility in construction and design. Their lightweight nature makes them easy to handle and install, reducing construction time and costs. Despite their light weight, these panels maintain excellent structural integrity, contributing to the overall stability of the building.

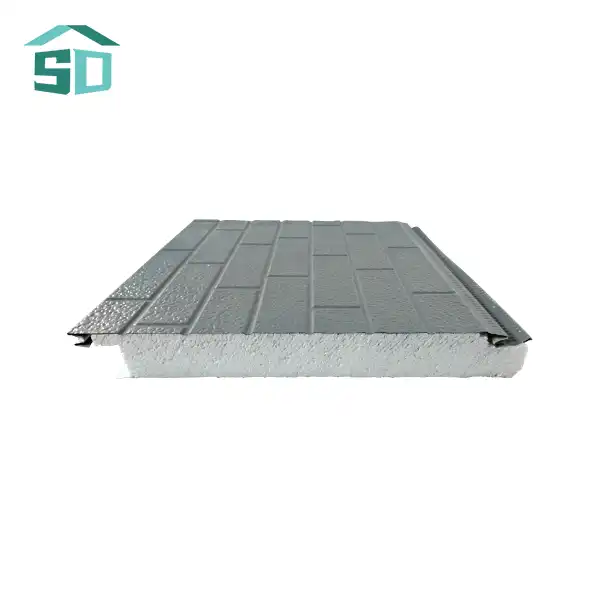

Architects and designers appreciate the flexibility offered by aluminum foam sandwich panels. They can be fabricated in various sizes and thicknesses to suit different project requirements. The panels can also be finished with a wide range of colors and textures, allowing for creative freedom in aesthetic design while maintaining high fire safety standards.

Energy Efficiency and Sustainability

Aluminum foam sandwich panels contribute significantly to energy efficiency in buildings. The cellular structure of the aluminum foam core provides excellent thermal insulation properties, helping to maintain comfortable indoor temperatures while reducing heating and cooling costs. This energy efficiency not only leads to cost savings but also contributes to the overall sustainability of the building.

From an environmental perspective, aluminum foam sandwich panels offer several benefits. Aluminum is a recyclable material, and the production process for these panels can incorporate recycled aluminum, reducing the demand for new raw materials. The long lifespan and durability of these panels also mean less frequent replacements, further minimizing environmental impact over time.

Future Trends and Innovations in Fire-Rated Aluminum Foam Panels

Advancements in Manufacturing Techniques

The field of aluminum foam sandwich panels is witnessing continuous innovation, particularly in manufacturing techniques. Researchers and aluminum foam sandwich panels suppliers are exploring advanced foaming processes to create even more uniform and controlled cellular structures within the foam core. These improvements aim to enhance not only the fire-resistant properties but also the overall performance of the panels.

One promising area of development is the use of 3D printing technology in the production of aluminum foam structures. This approach allows for precise control over the foam's cellular architecture, potentially leading to panels with optimized fire resistance and mechanical properties. Additionally, advancements in bonding technologies are improving the integration of the aluminum foam core with the face sheets, resulting in panels with enhanced durability and performance.

Integration of Smart Technologies

The future of aluminum foam sandwich panels may see the integration of smart technologies to further enhance fire safety. Researchers are exploring the incorporation of sensors within the panels that can detect temperature changes or the presence of smoke. These smart panels could potentially provide early warning systems, alerting building occupants and emergency services at the first sign of a fire.

Another innovative concept is the development of self-healing aluminum foam panels. These panels would be designed to automatically seal small cracks or damages, maintaining their fire-resistant integrity over time. While still in the early stages of research, such innovations could significantly enhance the long-term fire safety performance of buildings.

Expanding Applications in Various Industries

As awareness of the benefits of aluminum foam sandwich panels grows, their applications are expanding beyond traditional building construction. The aerospace industry, for instance, is showing increased interest in these panels for their combination of lightweight properties and fire resistance. In aircraft interiors, aluminum foam panels could provide enhanced safety without adding significant weight.

The marine industry is another sector where aluminum foam sandwich panels are gaining traction. Their corrosion resistance, coupled with fire-resistant properties, makes them ideal for shipbuilding applications. Similarly, in the automotive sector, these panels are being explored for use in electric vehicle battery enclosures, where fire safety is a critical concern.

Conclusion

Aluminum foam sandwich panels have proven to be exceptional performers in fire ratings, offering a remarkable combination of fire resistance, lightweight structure, and versatility. Their ability to achieve Class A fire ratings while providing excellent thermal insulation and design flexibility makes them a standout choice in modern construction. As manufacturing techniques continue to advance and new applications emerge, the future of aluminum foam sandwich panels in fire-safe building solutions looks increasingly promising. Their contribution to enhanced building safety, energy efficiency, and sustainability positions them as a key material in the evolution of fire-resistant construction technologies.

Are you looking for innovative, fire-resistant building materials that don't compromise on design or efficiency? Aluminum foam sandwich panels might be the solution you're seeking. At Weifang Sandong Building Materials Co., Ltd., we specialize in cutting-edge cladding and facade solutions, including high-performance aluminum foam sandwich panels. Whether you're an architect, contractor, or property developer, we're here to help you elevate your projects with our state-of-the-art products. Interested in learning more or discussing your specific needs? Don't hesitate to reach out to us at info@sdqsc.com.

FAQ

What makes aluminum foam sandwich panels fire-resistant?

The unique closed-cell structure of the aluminum foam core slows heat transfer and limits oxygen availability, enhancing fire resistance.

How do these panels compare to other fire-resistant materials?

Aluminum foam sandwich panels often outperform traditional materials in both fire resistance and overall performance, offering a superior balance of safety and functionality.

Are aluminum foam sandwich panels environmentally friendly?

Yes, they are recyclable and contribute to energy efficiency in buildings, making them a sustainable choice.

Can these panels be customized for different architectural designs?

Absolutely. They come in various sizes, thicknesses, and finishes, offering great flexibility in design while maintaining fire safety standards.

References

1. ASTM International. (2021). ASTM E84-21a Standard Test Method for Surface Burning Characteristics of Building Materials.

2. National Fire Protection Association. (2022). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.

3. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

4. Ashby, M. F., Evans, A., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

5. Baumeister, J., Banhart, J., & Weber, M. (1997). Aluminium foams for transport industry. Materials & Design, 18(4-6), 217-220.