Mechanical Properties and Load-Bearing Characteristics

The structural load capacity of aluminum foam sandwich panels is a testament to their innovative design and advanced materials. These panels exhibit remarkable mechanical properties that set them apart from traditional building materials. Let's delve into the key aspects that contribute to their impressive load-bearing capabilities:

Strength-to-Weight Ratio

One of the most striking features of aluminum foam sandwich panels is their exceptional strength-to-weight ratio. The cellular structure of the aluminum foam core allows for significant weight reduction without compromising structural integrity. This unique combination makes aluminum foam sandwich panels an ideal choice for applications where both strength and lightness are crucial, such as in aerospace or automotive industries.

Compressive and Tensile Strength

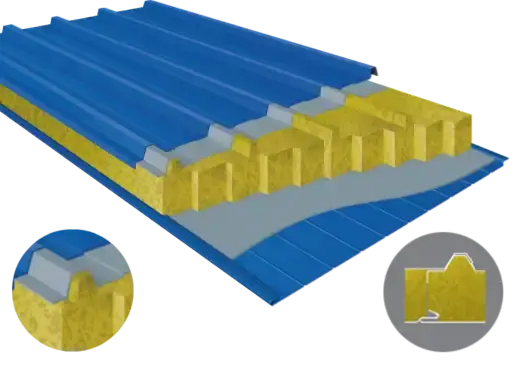

Aluminum foam sandwich panels demonstrate impressive compressive and tensile strength, largely due to their composite structure. The dense aluminum face sheets provide excellent resistance to tensile forces, while the foam core efficiently distributes compressive loads. This synergy results in a panel that can withstand substantial forces in multiple directions, making it suitable for diverse load-bearing applications.

Shear Resistance

The structural load capacity of aluminum foam sandwich panels extends to their ability to resist shear forces. The bonding between the face sheets and the foam core creates a unified structure that effectively resists deformation under shear stress. This property is particularly valuable in applications where torsional forces are a concern, such as in aircraft structures or high-rise building facades.

Factors Influencing Load Capacity

Several factors contribute to the structural load capacity of aluminum foam sandwich panels. Understanding these elements is crucial for optimizing panel performance and ensuring their effective application in various engineering scenarios.

Foam Core Density

The density of the aluminum foam core plays a significant role in determining the overall load capacity of the sandwich panel. Higher density cores generally provide increased strength and stiffness, albeit at the cost of added weight. Aluminum foam sandwich panels suppliers often offer a range of core densities, allowing engineers to select the optimal balance between strength and weight for specific applications.

Face Sheet Thickness

The thickness of the aluminum face sheets directly impacts the panel's bending stiffness and load-bearing capacity. Thicker face sheets enhance the overall strength of the panel but may increase its weight. Engineers must carefully consider the trade-off between strength and weight when specifying face sheet thickness for aluminum foam sandwich panels.

Panel Geometry

The overall geometry of aluminum foam sandwich panels, including their length, width, and thickness, significantly influences their load-bearing capabilities. Panels with optimized aspect ratios can achieve higher structural efficiency, allowing for maximum load capacity with minimal material usage. This aspect of design is particularly crucial when using aluminum foam sandwich panels in weight-sensitive applications.

Applications Leveraging Structural Load Capacity

The impressive structural load capacity of aluminum foam sandwich panels has led to their adoption in a wide range of industries and applications. These versatile panels offer solutions to complex engineering challenges across various sectors.

Aerospace Industry

In the aerospace sector, the high strength-to-weight ratio of aluminum foam sandwich panels makes them invaluable for aircraft structures. These panels are utilized in floor panels, bulkheads, and interior components, where they provide excellent load-bearing capacity while contributing to overall weight reduction. The use of aluminum foam sandwich panels in aerospace applications demonstrates their ability to meet stringent safety and performance standards.

Automotive Engineering

The automotive industry has embraced aluminum foam sandwich panels for their ability to enhance vehicle safety and efficiency. These panels are employed in crash-absorbing structures, where their energy absorption properties and structural integrity provide superior protection. Additionally, the lightweight nature of aluminum foam sandwich panels contributes to improved fuel efficiency and reduced emissions in vehicles.

Building and Construction

In the construction sector, aluminum foam sandwich panels offer innovative solutions for both structural and aesthetic applications. Their high load-bearing capacity makes them suitable for use in facade systems, roofing, and flooring. The panels' ability to span large distances without intermediate supports, combined with their excellent thermal insulation properties, makes them a popular choice for modern, energy-efficient building designs.

Conclusion

The structural load capacity of aluminum foam sandwich panels represents a significant advancement in materials science and engineering. These innovative panels offer a unique combination of strength, lightness, and versatility that makes them invaluable across multiple industries. From their impressive strength-to-weight ratio to their ability to withstand various types of loads, aluminum foam sandwich panels have proven their worth in demanding applications. As technology continues to evolve, we can expect further refinements in the design and manufacturing of these panels, leading to even more impressive load-bearing capabilities and broader applications.

Are you looking for cutting-edge solutions for your next project? Discover the potential of aluminum foam sandwich panels with Weifang Sandong Building Materials Co., Ltd. Our expert team is ready to help you harness the power of these innovative materials for your specific needs. Contact us today at info@sdqsc.com to explore how our aluminum foam sandwich panels can elevate your construction or engineering project to new heights of performance and efficiency.

FAQ

What makes aluminum foam sandwich panels unique in terms of load capacity?

Their exceptional strength-to-weight ratio, due to the aluminum foam core sandwiched between dense face sheets, allows for high load-bearing capacity with minimal weight.

Can aluminum foam sandwich panels be customized for specific load requirements?

Yes, parameters like core density, face sheet thickness, and overall panel geometry can be tailored to meet specific load capacity needs.

Are aluminum foam sandwich panels suitable for outdoor applications?

Absolutely. These panels offer excellent corrosion resistance and can be treated for enhanced weather protection, making them ideal for exterior use.

References

1. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

2. Ashby, M. F., Evans, A., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

3. Crupi, V., Epasto, G., & Guglielmino, E. (2013). Comparison of aluminium sandwiches for lightweight ship structures: Honeycomb vs. foam. Marine Structures, 30, 74-96.

4. Lefebvre, L. P., Banhart, J., & Dunand, D. C. (2008). Porous Metals and Metallic Foams: Current Status and Recent Developments. Advanced Engineering Materials, 10(9), 775-787.

5. Styles, M., Compston, P., & Kalyanasundaram, S. (2007). The effect of core thickness on the flexural behaviour of aluminium foam sandwich structures. Composite Structures, 80(4), 532-538.