Structural Integrity and Load-Bearing Capacity

Compressive Strength and Density

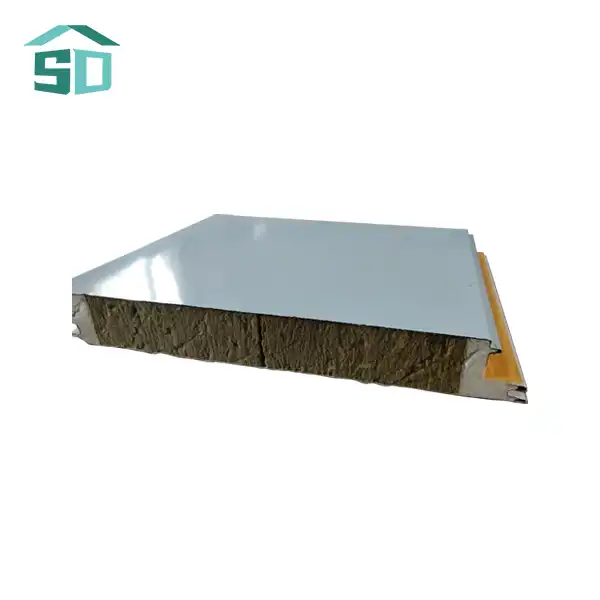

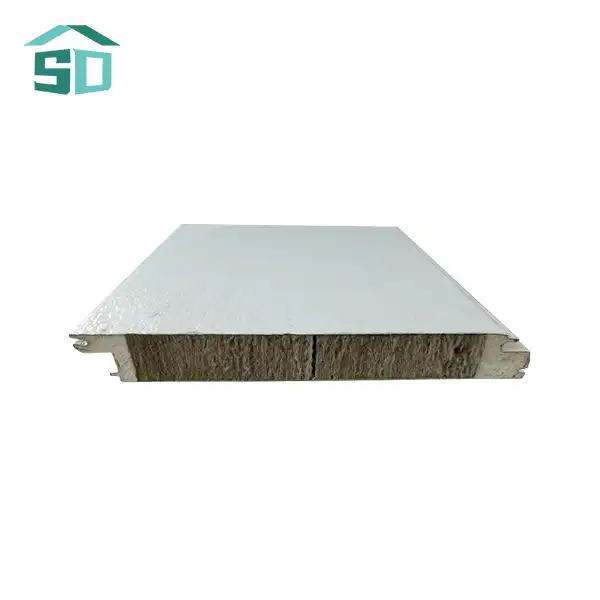

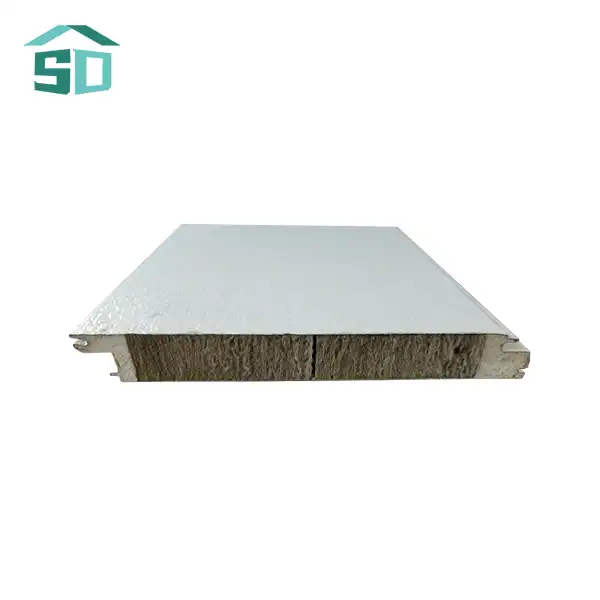

Aluminum foam sandwich panels showcase remarkable compressive strength, a crucial factor in their structural integrity. The unique cellular structure of aluminum foam allows for impressive load distribution, enabling these panels to withstand significant compressive forces without compromising their shape or functionality. This property is particularly valuable in applications where weight reduction is essential, such as in aerospace or automotive industries.

The density of aluminum foam cores can be tailored to specific requirements, typically ranging from 0.15 to 0.5 g/cm³. This customization allows engineers to optimize the balance between strength and weight, creating panels that are both robust and lightweight. In contrast, mineral wool cores generally have lower compressive strength and higher density, which can limit their applications in high-load scenarios.

Shear Strength and Flexural Rigidity

Shear strength is another area wherealuminum foam sandwich panels excel. The interconnected network of aluminum cells provides superior resistance to shear forces, preventing delamination and maintaining the panel's structural integrity under various stress conditions. This property is particularly beneficial in applications involving dynamic loads or vibrations.

The flexural rigidity of aluminum foam cores contributes significantly to the overall stiffness of the sandwich panel. This enhanced rigidity allows for the creation of larger spans with minimal deflection, a characteristic that is highly valued in architectural and engineering projects. Mineral wool cores, while offering good insulation properties, typically exhibit lower shear strength and flexural rigidity compared to their aluminum foam counterparts.

Impact Resistance and Energy Absorption

One of the most distinctive features of aluminum foam sandwich panels is their exceptional impact resistance and energy absorption capabilities. The cellular structure of aluminum foam allows it to absorb and dissipate kinetic energy effectively, making these panels ideal for applications requiring protection against impacts or explosions.

This property is particularly valuable in industries such as defense, where blast-resistant structures are crucial. The energy absorption capacity of aluminum foam cores far exceeds that of mineral wool cores, providing superior protection and safety in high-risk environments.

Thermal and Acoustic Performance

Thermal Insulation Properties

While aluminum foam sandwich panels offer impressive mechanical properties, their thermal insulation capabilities are generally lower compared to mineral wool cores. The thermal conductivity of aluminum foam, typically ranging from 0.3 to 10 W/mK depending on density, is higher than that of mineral wool, which usually falls between 0.03 and 0.04 W/mK.

However, the closed-cell structure of aluminum foam does provide some insulation benefits, and when combined with additional insulating layers, these panels can still achieve satisfactory thermal performance. For applications where thermal insulation is paramount, hybrid solutions combining aluminum foam with other insulating materials can be employed to leverage the strengths of both materials.

Acoustic Damping and Sound Insulation

In terms of acoustic performance, aluminum foam sandwich panelsdemonstrate interesting properties. The cellular structure of aluminum foam provides natural sound damping capabilities, effectively absorbing and dissipating sound waves across a wide frequency range. This characteristic makes these panels suitable for applications requiring noise reduction, such as in automotive or aerospace industries.

While mineral wool cores generally offer superior sound insulation due to their fibrous nature, aluminum foam panels can be engineered to achieve comparable acoustic performance through careful design of the foam structure and panel composition. The ability to tailor the acoustic properties of aluminum foam sandwich panels adds to their versatility in various applications.

Fire Resistance and Safety Considerations

Fire safety is a critical consideration in many applications, and here, mineral wool cores traditionally hold an advantage. Mineral wool is inherently non-combustible and provides excellent fire resistance. However, advancements in aluminum foam technology have led to the development of fire-resistant aluminum foam sandwich panels that meet stringent safety standards.

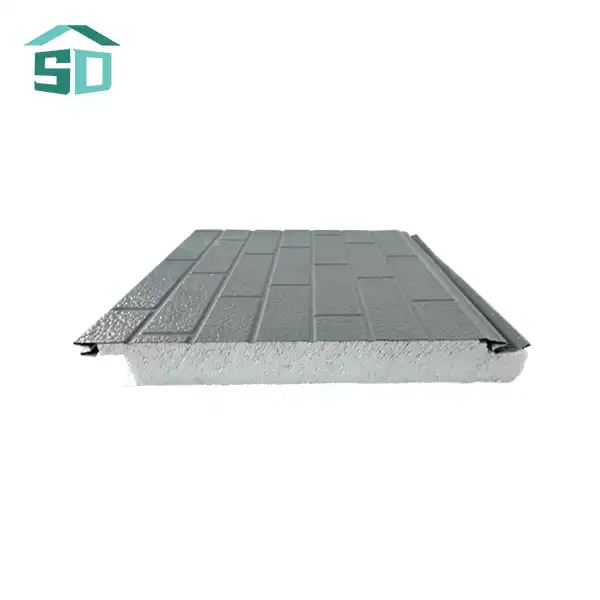

These advanced aluminum foam panels incorporate fire-retardant additives or coatings, enhancing their fire resistance properties. While they may not match the inherent fire resistance of mineral wool, they offer a compelling combination of structural strength, lightweight design, and improved fire safety. This makes aluminum foam sandwich panels a viable option in applications where fire resistance is crucial, such as in building façades or transportation interiors.

Durability and Environmental Impact

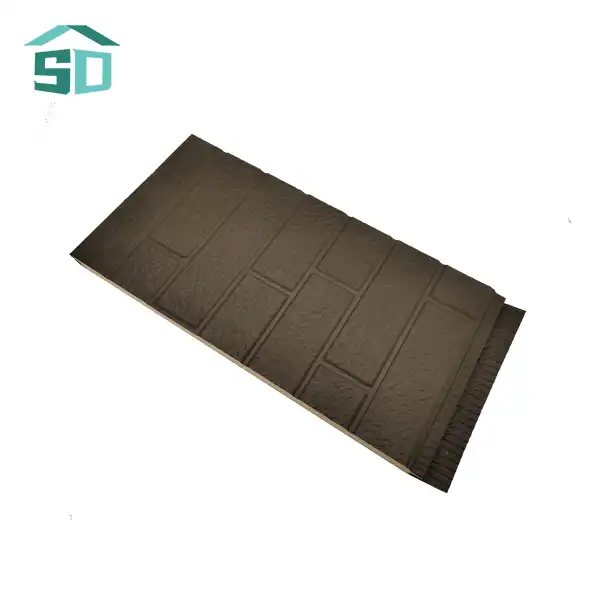

Corrosion Resistance and Weatherability

Aluminum foam sandwich panels exhibit excellent corrosion resistance, a significant advantage in many applications. The inherent properties of aluminum, combined with the closed-cell structure of the foam, provide robust protection against environmental factors such as moisture, UV radiation, and chemical exposure. This durability ensures long-term performance and reduced maintenance requirements, particularly in harsh or corrosive environments.

In contrast, mineral wool cores may require additional protective measures to prevent moisture absorption and maintain their insulation properties over time. The superior weatherability of aluminum foam sandwich panels makes them particularly suitable for exterior applications, where they can withstand the elements while maintaining their structural and aesthetic integrity.

Lifecycle Assessment and Recyclability

From an environmental perspective, aluminum foam sandwich panels offer several advantages. Aluminum is highly recyclable, with the potential for multiple recycling cycles without significant loss of properties. This recyclability contributes to the overall sustainability of aluminum foam panels, reducing their environmental impact over the product lifecycle.

Moreover, the lightweight nature of these panels can lead to reduced transportation costs and lower carbon emissions associated with shipping and handling. While mineral wool is also recyclable, the process can be more energy-intensive compared to aluminum recycling. The long lifespan and durability of aluminum foam sandwich panels further enhance their environmental credentials by reducing the need for frequent replacements.

Manufacturing Process and Energy Efficiency

The manufacturing process of aluminum foam sandwich panels has seen significant advancements in recent years, leading to improved energy efficiency and reduced environmental impact. Modern production techniques allow for precise control over foam density and cell structure, optimizing material usage and minimizing waste.

While the initial energy input for aluminum production is considerable, the longevity and recyclability of aluminum foam panels offset this over their lifecycle. In comparison, mineral wool production typically involves lower initial energy requirements but may result in higher cumulative energy consumption due to more frequent replacements in certain applications.

Conclusion

In conclusion, the comparison between aluminum foam and mineral wool cores reveals distinct advantages for each material. Aluminum foam sandwich panels excel in structural performance, offering superior strength-to-weight ratios, impact resistance, and customizable properties. Their durability, corrosion resistance, and recyclability make them an attractive option for various applications. While mineral wool cores maintain an edge in thermal insulation and inherent fire resistance, advancements in aluminum foam technology continue to narrow this gap. The choice between these materials ultimately depends on specific project requirements, balancing factors such as mechanical performance, insulation needs, and environmental considerations.

As a leading aluminum foam sandwich panels supplier, Weifang Sandong Building Materials Co., Ltd. offers innovative solutions that leverage the unique properties of aluminum foam cores. Our panels combine exceptional strength, lightweight design, and customizable features to meet diverse project needs. Whether you're looking for durable exterior cladding, high-performance insulated panels, or specialized applications, our expert team is ready to assist you. Discover how our aluminum foam sandwich panels can elevate your next project by contacting us at info@sdqsc.com.

FAQ

What are the main advantages of aluminum foam sandwich panels?

Aluminum foam sandwich panels offer excellent strength-to-weight ratios, superior impact resistance, and customizable properties. They are also highly durable, corrosion-resistant, and recyclable.

How do aluminum foam cores compare to mineral wool in terms of thermal insulation?

While mineral wool generally provides better thermal insulation, aluminum foam cores can be engineered to offer satisfactory thermal performance, especially when combined with additional insulating layers.

Are aluminum foam sandwich panels suitable for exterior applications?

Yes, these panels are ideal for exterior use due to their excellent weatherability, corrosion resistance, and ability to withstand harsh environmental conditions.

References

1.Ashby, M. F., et al. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

2.Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

3.Gibson, L. J., & Ashby, M. F. (1997). Cellular Solids: Structure and Properties. Cambridge University Press.

4.Lefebvre, L. P., Banhart, J., & Dunand, D. C. (2008). Porous Metals and Metallic Foams: Current Status and Recent Developments. Advanced Engineering Materials, 10(9), 775-787.

5.Wadley, H. N. G. (2002). Cellular Metals Manufacturing. Advanced Engineering Materials, 4(10), 726-733.