- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Choosing the Right Steel PU Sandwich Panel

Selecting the ideal steel PU sandwich panels for your construction project requires careful consideration of various factors. These versatile building materials offer a unique combination of strength, insulation, and aesthetic appeal. To make an informed decision, evaluate the panel's thickness, insulation properties, fire resistance, and customization options. Consider your specific project requirements, climate conditions, and budget constraints. By choosing the right steel PU sandwich panel, you can enhance energy efficiency, durability, and overall building performance while achieving a sleek, modern appearance.

Understanding Steel PU Sandwich Panels: Composition and Benefits

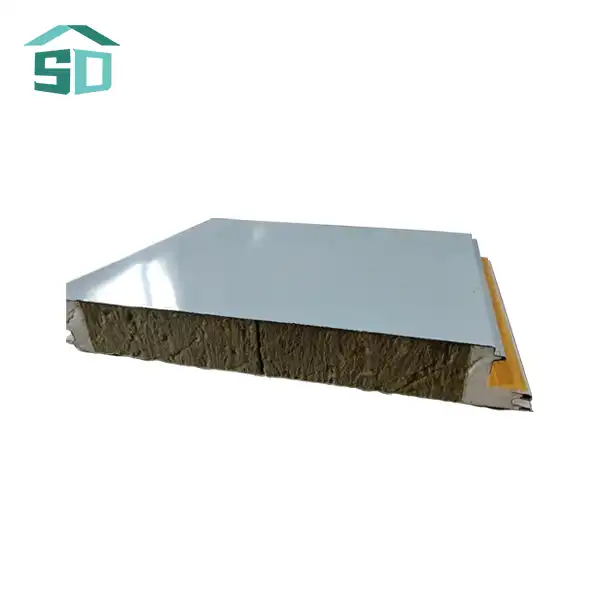

Steel PU sandwich panels are composite building materials consisting of two metal facings with a polyurethane foam core. This unique structure offers numerous advantages for construction projects across various industries.

Composition of Steel PU Sandwich Panels

The outer layers of steel PU sandwich panels are typically made from high-quality galvanized steel, providing exceptional strength and durability. These steel facings are coated with a protective layer to enhance corrosion resistance and longevity. The core of the panel is composed of rigid polyurethane foam, a material renowned for its superior insulation properties.

Key Benefits of Steel PU Sandwich Panels

Steel PU sandwich panels offer a myriad of benefits that make them an attractive choice for modern construction:

- Exceptional Thermal Insulation: The polyurethane core provides outstanding thermal performance, helping maintain comfortable indoor temperatures and reducing energy costs.

- Lightweight Yet Strong: Despite their relatively light weight, these panels offer remarkable structural strength, simplifying installation and reducing the load on building foundations.

- Fire Resistance: Many steel PU sandwich panels are engineered with fire-resistant properties, enhancing building safety.

- Moisture and Corrosion Resistance: The steel facings and protective coatings guard against moisture infiltration and corrosion, extending the lifespan of the panels.

- Versatility: These panels are suitable for various applications, including walls, roofs, and interior partitions in residential, commercial, and industrial buildings.

- Aesthetic Appeal: Steel PU sandwich panels are available in a wide range of colors and finishes, allowing for customization to suit diverse architectural styles.

Factors to Consider When Choosing Steel PU Sandwich Panels

To select the most appropriate steel PU sandwich panel for your project, consider the following crucial factors:

Panel Thickness and Insulation Performance

The thickness of a steel PU sandwich panel directly impacts its insulation capabilities. Thicker panels generally offer better thermal performance, but they may also increase costs and affect the building's overall dimensions. Common thicknesses range from 50mm to 100mm, with customization options available. Evaluate your project's specific insulation requirements and climate conditions to determine the optimal panel thickness.

Fire Safety and Ratings

Fire resistance is a critical consideration, especially in commercial and industrial applications. Look for steel PU sandwich panels with high fire ratings, such as Class A, which indicate non-combustible properties. These panels can significantly enhance the overall fire safety of your building, providing valuable time for evacuation in the event of a fire.

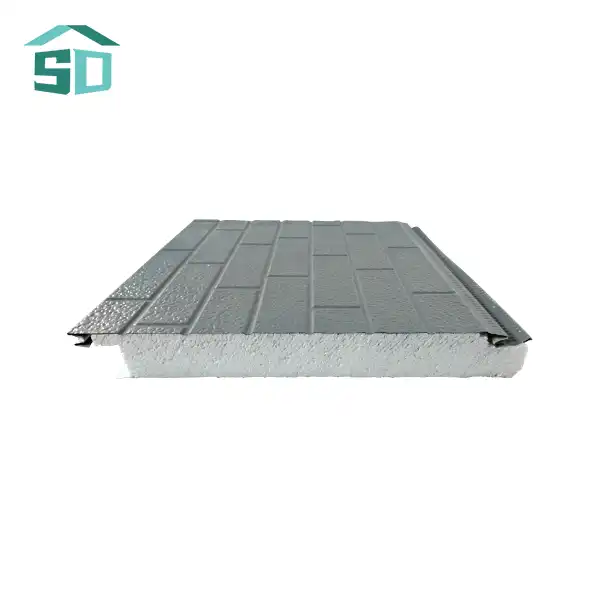

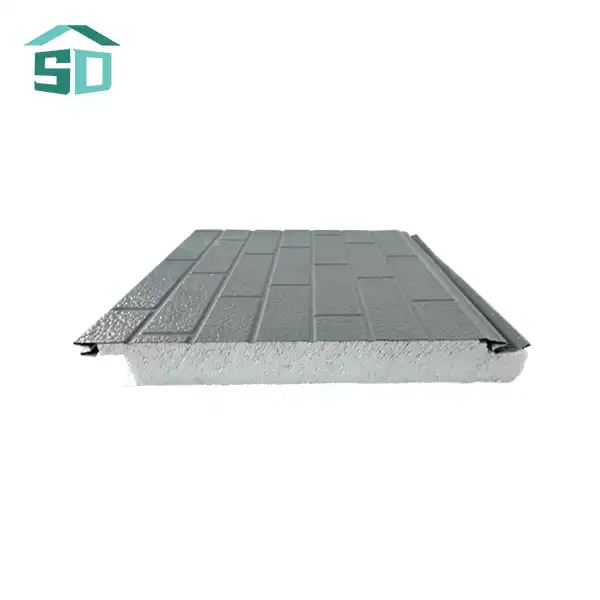

Customization Options and Aesthetic Considerations

Steel PU sandwich panels offer extensive customization possibilities to meet your project's aesthetic requirements. Consider the following options:

- Color Selection: Choose from a wide range of colors using standard RAL color charts to match your design vision.

- Surface Finishes: Select from various textures and patterns to achieve the desired visual effect.

- Panel Dimensions: Customize the length of panels (up to 12m) to minimize joints and enhance the overall appearance.

- Edge Profiles: Opt for different edge profiles to create seamless connections between panels.

Durability and Weather Resistance

Assess the panel's ability to withstand environmental factors such as UV radiation, temperature fluctuations, and moisture exposure. Look for panels with high-quality protective coatings and robust steel facings to ensure long-term performance and reduced maintenance requirements.

Installation and Maintenance Considerations

Proper installation and maintenance are crucial for maximizing the performance and longevity of steel PU sandwich panels.

Installation Best Practices

To ensure optimal performance and longevity of your steel PU sandwich panels, follow these installation guidelines:

- Surface Preparation: Ensure the supporting structure is clean, dry, and properly aligned before panel installation.

- Panel Alignment: Carefully position panels to maintain proper alignment and ensure a seamless appearance.

- Fastening Methods: Use appropriate fasteners and follow manufacturer recommendations for secure attachment.

- Sealing: Apply high-quality sealants to joints and edges to prevent moisture infiltration and maintain insulation efficiency.

- Professional Installation: Consider hiring experienced professionals to ensure proper installation and maximize panel performance.

Maintenance Requirements

While steel PU sandwich panels are relatively low-maintenance, regular upkeep can significantly extend their lifespan:

- Periodic Inspections: Conduct visual inspections to identify any damage, loose fasteners, or sealant degradation.

- Cleaning: Regularly clean panels using mild detergents and soft brushes to remove dirt and debris.

- Repair and Replacement: Address any damage promptly to prevent moisture infiltration and maintain panel integrity.

- Recoating: Consider recoating panels after several years to refresh their appearance and enhance protection against environmental factors.

Conclusion

Choosing the right steel PU sandwich panel is a crucial decision that can significantly impact the performance, efficiency, and aesthetics of your building project. By carefully considering factors such as insulation properties, fire resistance, customization options, and installation requirements, you can select panels that perfectly align with your project goals. Steel PU sandwich panels offer a winning combination of durability, energy efficiency, and design flexibility, making them an excellent choice for a wide range of construction applications.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing high-quality steel PU sandwich panels that meet the diverse needs of our customers. Our panels feature robust steel frames for enduring beauty, superior insulation with PU cores, and customizable appearances to fit your vision. Whether you're working on a residential, commercial, or industrial project, our expert team is here to help you choose the perfect steel PU sandwich panels factory for your needs. Contact us today at info@sdqsc.com to learn more about our products and how we can contribute to the success of your construction project.

FAQ

What are the typical applications for steel PU sandwich panels?

Steel PU sandwich panels are versatile and can be used in various applications, including exterior walls, roofs, and interior partitions in residential, commercial, and industrial buildings. They are also commonly used in cold storage facilities, cleanrooms, and modular construction projects.

How do steel PU sandwich panels contribute to energy efficiency?

The polyurethane core in steel PU sandwich panels provides excellent thermal insulation, reducing heat transfer between the interior and exterior of a building. This helps maintain consistent indoor temperatures, reducing the need for heating and cooling, and ultimately lowering energy consumption and costs.

Are steel PU sandwich panels environmentally friendly?

Yes, steel PU sandwich panels can be considered environmentally friendly. They contribute to energy efficiency in buildings, and many panels are made from recyclable materials. Additionally, their durability and long lifespan reduce the need for frequent replacements, minimizing waste in the long term.

References

1. American Iron and Steel Institute. (2021). "Steel Industry Technology Roadmap for Automotive."

2. Building Science Corporation. (2020). "Guide to Insulating Sheathing."

3. International Code Council. (2021). "International Building Code."

4. National Fire Protection Association. (2022). "NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components."

5. U.S. Department of Energy. (2021). "Insulation Materials."