As sustainable building practices gain momentum, steel PU sandwich panels align closely with green construction goals. Their excellent energy-efficient properties help reduce carbon footprints and lower operational energy costs for buildings. Additionally, the panels offer a long service life and are recyclable at the end of their use, further supporting eco-friendly initiatives. Architects and developers increasingly incorporate steel PU sandwich panels into LEED-certified projects and other environmentally conscious designs, recognizing their contribution to sustainability and responsible resource use.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best Uses for Steel PU Sandwich Panels in Construction

Steel PU sandwich panels have revolutionized the construction industry with their versatility, durability, and energy efficiency. These panels, composed of two steel sheets with a polyurethane foam core, offer a myriad of benefits for various construction applications. From residential complexes to industrial facilities, steel PU sandwich panels provide superior insulation, structural integrity, and aesthetic appeal. This article explores the best uses of steel PU sandwich panels in construction, highlighting their advantages and showcasing their adaptability across different projects.

Versatile Applications in Building Envelopes

Exterior Wall Cladding

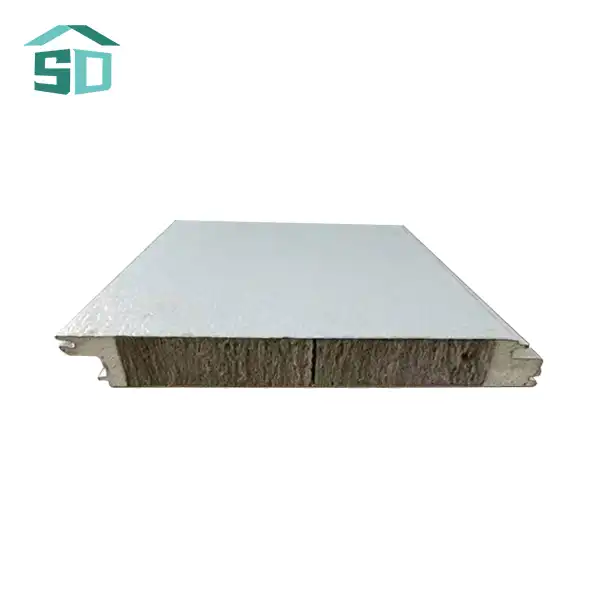

Steel PU sandwich panels excel as exterior wall cladding solutions. Their robust construction and weatherproof properties make them ideal for protecting buildings from harsh environmental conditions such as heavy rain, strong winds, and extreme temperatures. The panels' high-density polyurethane core ensures excellent thermal insulation, effectively reducing heat transfer and significantly enhancing overall energy efficiency. Architects and builders appreciate these panels for their ability to create sleek, modern facades that combine aesthetic appeal with lasting structural integrity and durability in diverse climates.

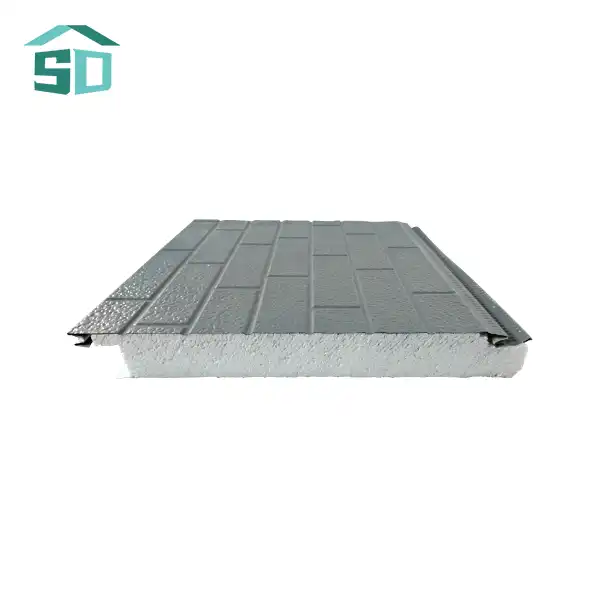

Roofing Systems

In roofing applications, steel PU sandwich panels deliver unparalleled performance and reliability. Their lightweight yet strong composition facilitates easy installation, saving time and labor without sacrificing durability or strength. The panels feature an interlocking design that creates a watertight seal, effectively preventing leaks and moisture infiltration even in severe weather. Additionally, the polyurethane core offers superior insulation, which helps reduce cooling and heating costs for building occupants, contributing to improved comfort and energy savings throughout the year.

Interior Partitions

Steel PU sandwich panels are versatile and extend beyond exterior uses to serve as efficient interior partitions in commercial and industrial spaces. Their sound-dampening properties help create quieter, more comfortable work environments by reducing noise transmission between rooms. Furthermore, their fire-resistant qualities enhance building safety and compliance with regulations. The panels are easy to install and come with customizable finishes, making them a popular choice for creating flexible, modular interior layouts tailored to specific functional and aesthetic needs.

Industrial and Commercial Applications

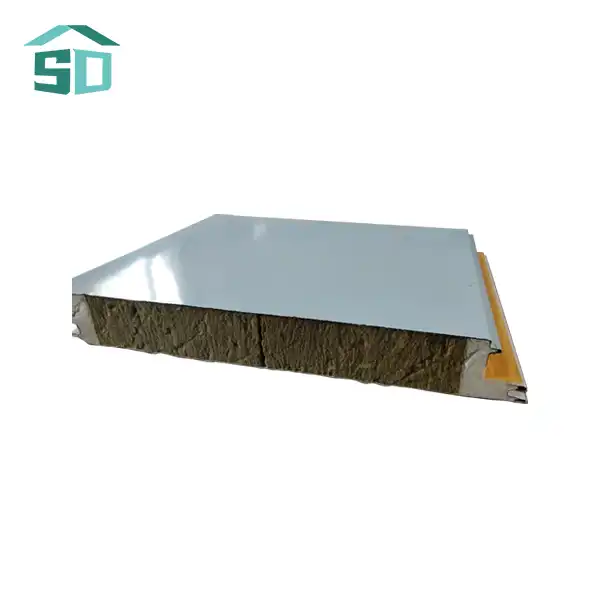

Cold Storage Facilities

The exceptional insulation properties of steel PU sandwich panels make them indispensable for cold storage construction. These panels maintain consistent temperatures in refrigerated warehouses, food processing plants, and distribution centers, ensuring product quality and integrity. Their moisture resistance helps prevent condensation and bacterial growth, critical factors for hygiene-sensitive environments. By reducing energy consumption and supporting precise temperature control, steel PU sandwich panels contribute significantly to the efficiency and sustainability of cold storage operations.

Agricultural Buildings

Steel PU sandwich panels are extensively used in agricultural construction, providing durable and low-maintenance solutions for various structures such as barns, storage sheds, and livestock housing. Their excellent insulation properties help regulate temperatures, creating comfortable environments for animals and optimal conditions for crop storage. The panels' corrosion-resistant surfaces ensure long-term durability even in harsh farming conditions, including exposure to moisture, chemicals, and fluctuating weather, making them a practical and reliable choice for agricultural applications.

Manufacturing Facilities

In industrial manufacturing environments, steel PU sandwich panels provide versatile and practical solutions for walls, roofs, and ceilings. Their inherent fire-resistant properties and resistance to chemical exposure meet stringent safety and regulatory requirements common in production facilities. The panels' smooth, non-porous surfaces facilitate easy cleaning and maintenance, which is crucial in industries where hygiene is paramount. These features make steel PU sandwich panels ideal for maintaining safe, efficient, and compliant manufacturing spaces.

Specialized Construction Projects

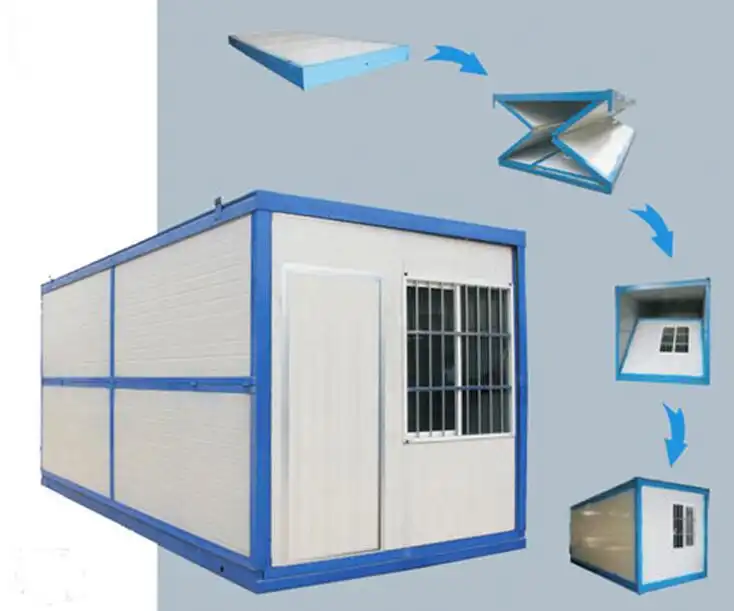

Modular and Prefabricated Buildings

The construction industry's shift towards modular and prefabricated building methods has amplified the demand for steel PU sandwich panels. These panels' lightweight nature and standardized dimensions make them ideal for off-site construction. They enable rapid assembly of modular units, reducing on-site construction time and labor costs. From temporary structures to permanent modular buildings, steel PU sandwich panels offer flexibility and efficiency in prefabricated construction.

Renovation and Retrofitting

Steel PU sandwich panels are invaluable in renovation and retrofitting projects, providing a cost-effective method for upgrading existing structures. Their design allows installation over current building envelopes with minimal structural modifications, avoiding extensive demolition or reconstruction. This enables older buildings to achieve improved energy efficiency, updated aesthetic appeal, and enhanced structural integrity. The panels’ adaptability makes them an ideal choice for modernizing facilities while minimizing project disruption and expense.

Sustainable Building Design

Conclusion

Steel PU sandwich panels have emerged as a versatile and indispensable component in modern construction. Their applications span a wide range of projects, from residential and commercial buildings to specialized industrial facilities. The panels' combination of strength, insulation, and aesthetic flexibility makes them a preferred choice for architects, builders, and property owners alike. As construction technologies continue to evolve, steel PU sandwich panels are poised to play an increasingly significant role in shaping the built environment of the future.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality steel PU sandwich panels that meet the diverse needs of the construction industry. Our advanced production lines and rigorous quality control ensure that every panel meets the highest standards of performance and durability. Whether you're embarking on a new construction project or renovating an existing structure, our steel PU sandwich panels offer the perfect solution for your building envelope needs. Contact us at info@sdqsc.com to learn more about how our products can enhance your next construction project.

FAQ

What thicknesses are available for steel PU sandwich panels?

Our steel PU sandwich panels are available in thicknesses of 50mm, 75mm, and 100mm, with custom options available to meet specific project requirements.

Are steel PU sandwich panels fire-resistant?

Yes, our panels have a Class A fire rating, ensuring compliance with building regulations and providing enhanced safety in various construction applications.

Can steel PU sandwich panels be customized in terms of color and finish?

Absolutely. We offer a wide range of color options based on the RAL color chart, allowing for customization to suit your project's aesthetic needs.

How do steel PU sandwich panels contribute to energy efficiency?

The high-density polyurethane core provides excellent thermal insulation, significantly reducing heat transfer and lowering energy costs for heating and cooling.

References

1.Building Design & Construction. (2022). "Innovative Building Materials: The Rise of Sandwich Panels in Construction."

2.Journal of Construction Engineering. (2021). "Energy Efficiency in Modern Building Envelopes: A Comparative Study of Insulation Materials."

3.Architectural Review. (2023). "Sustainable Construction Practices: The Role of Advanced Building Materials."

4.International Journal of Civil Engineering. (2022). "Structural Performance of Steel-Faced Sandwich Panels in Building Applications."

5.Green Building Council. (2023). "Materials and Resources Credit: Environmental Product Declarations (EPD)."