The Science Behind Polyurethane Foam's Moisture-Blocking Properties

Chemical Composition and Structure

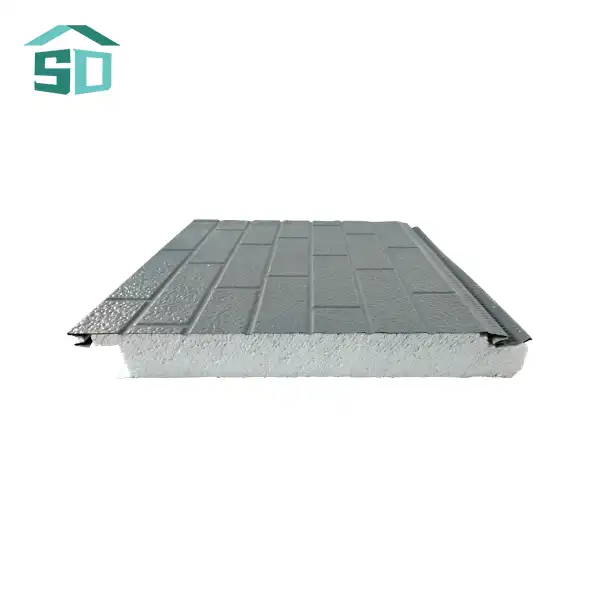

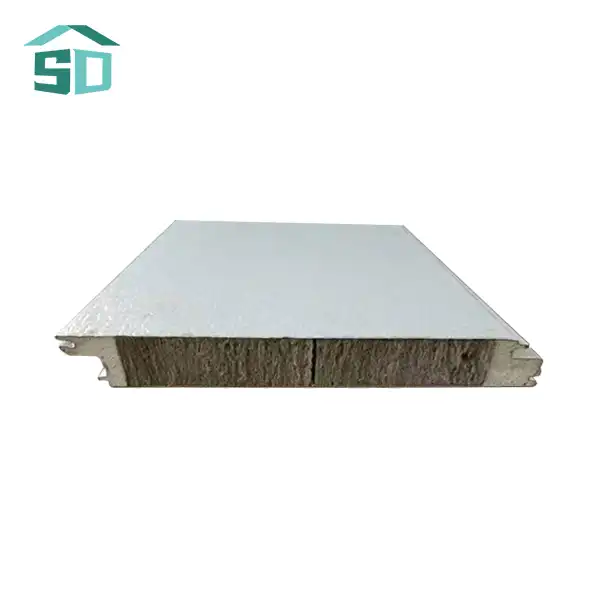

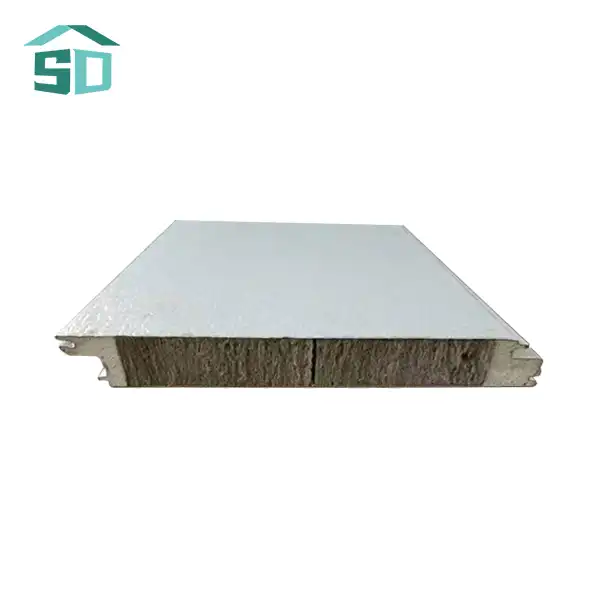

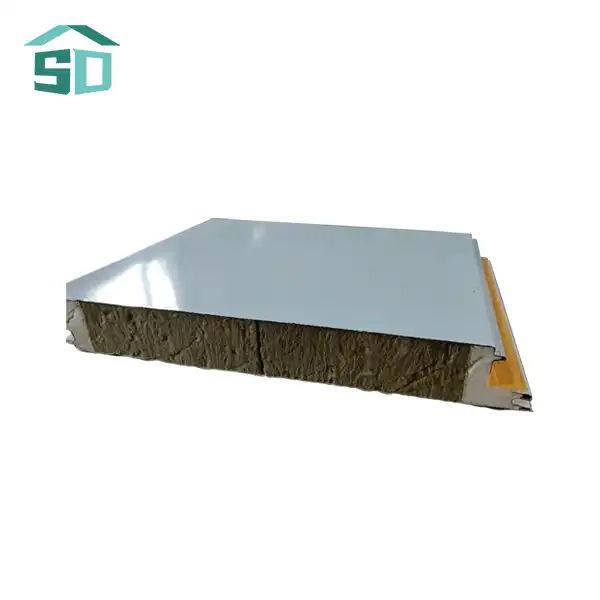

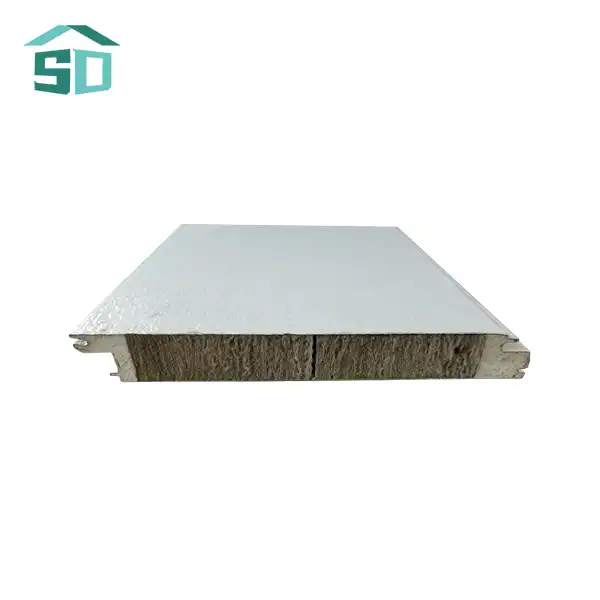

Polyurethane foam insulation panels owe their moisture-blocking prowess to their unique chemical composition and cellular structure. The foam is created through a reaction between polyol and isocyanate, forming a dense network of closed cells. These cells are filled with low-conductivity gas, creating tiny pockets that effectively trap air and resist water penetration.

The closed-cell structure of polyurethane foam is key to its moisture-blocking capabilities. Unlike open-cell foams, closed-cell polyurethane creates a barrier that water molecules cannot easily penetrate. This structure not only prevents liquid water from entering but also inhibits water vapor transmission, making it an excellent choice for controlling humidity levels within buildings.

Advanced Manufacturing Techniques

The manufacturing process of polyurethane foam insulation panels has been refined to enhance their moisture-resistant properties. Modern production techniques ensure uniformity in cell size and distribution, maximizing the foam's ability to repel water. Additionally, the incorporation of hydrophobic additives during the manufacturing process further boosts the material's water-repellent characteristics.

These advanced techniques result in panels with consistent density and thermal conductivity ratings. With thermal conductivity values as low as ≤ 0.022 W/(m·K), these panels offer superior insulation performance while maintaining their moisture barrier properties. This combination of features makes polyurethane foam insulation panels a versatile solution for various climates and building types.

Benefits of Polyurethane Foam Insulation Panels in Moisture Control

Enhanced Building Envelope Performance

Polyurethane foam insulation panels significantly improve the overall performance of building envelopes. By creating a seamless barrier against moisture intrusion, these panels help maintain the structural integrity of buildings over time. This protection is particularly crucial in areas prone to high humidity or frequent precipitation, where traditional insulation materials may fall short.

The panels' ability to control moisture migration also contributes to better indoor air quality. By preventing the accumulation of moisture within wall cavities, polyurethane foam insulation panels reduce the risk of mold growth and associated health issues. This aspect is especially valuable in healthcare facilities, schools, and residential buildings where occupant health is a primary concern.

Energy Efficiency and Cost Savings

The moisture-blocking properties of polyurethane foam insulation panels directly contribute to improved energy efficiency. By preventing moisture from compromising the insulation's effectiveness, these panels maintain their thermal performance over time. This consistency translates to reduced heating and cooling costs for building owners and occupants.

Moreover, the longevity of polyurethane foam insulation panels means less frequent replacement and maintenance. With a lifespan often exceeding 25 years, these panels offer a cost-effective solution for long-term moisture control and energy efficiency. The initial investment in high-quality polyurethane foam insulation panels is typically offset by substantial energy savings and reduced maintenance costs over the building's lifetime.

Application and Installation Considerations

Versatility in Construction Projects

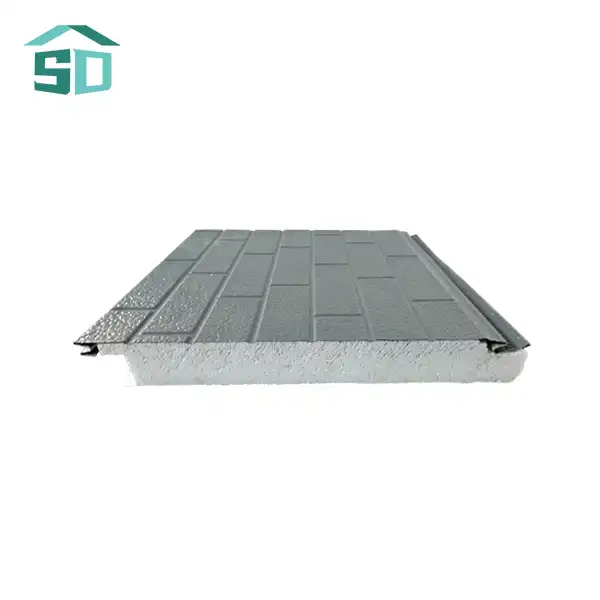

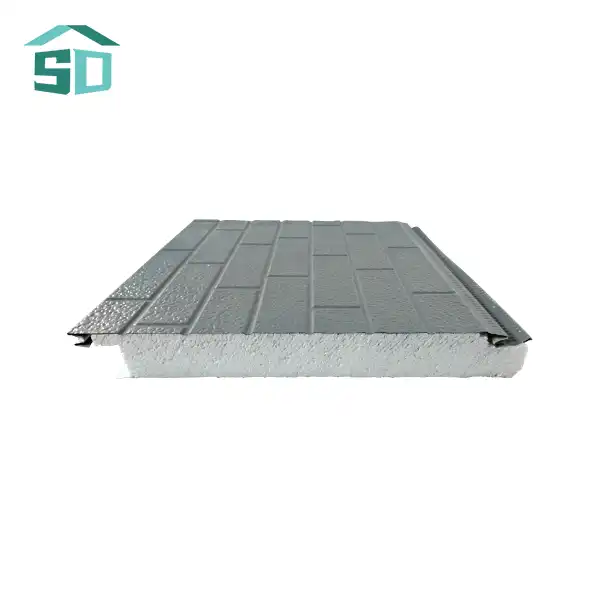

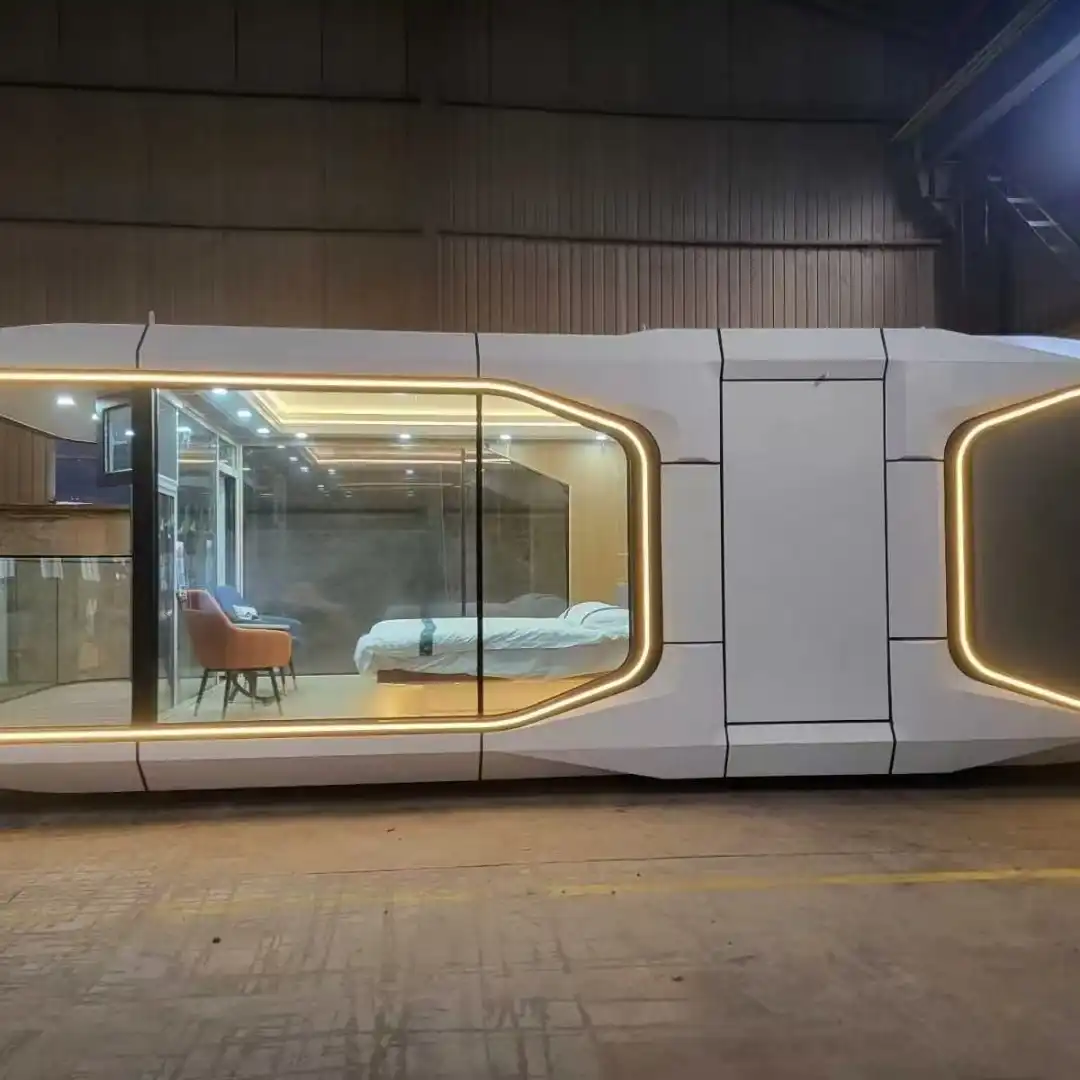

Polyurethane foam insulation panels demonstrate remarkable versatility across various construction applications. Their moisture-blocking properties make them suitable for both new construction and renovation projects. In residential settings, these panels excel in insulating exterior walls, roofs, and foundations, providing comprehensive moisture protection throughout the home.

Commercial and industrial applications benefit equally from the panels' moisture-resistant qualities. From warehouses and cold storage facilities to office buildings and manufacturing plants, polyurethane foam insulation panels offer a reliable solution for maintaining dry, energy-efficient environments. Their adaptability to different surface types and architectural designs makes them a favorite among architects and builders seeking high-performance insulation solutions.

Professional Installation for Optimal Performance

While polyurethane foam insulation panels are designed for ease of installation, professional application is crucial for maximizing their moisture-blocking potential. Proper installation ensures that panels form a continuous barrier without gaps or seams that could compromise their effectiveness. Experienced installers understand the importance of proper sealing techniques, especially around joints, windows, and other potential entry points for moisture.

The installation process typically involves careful preparation of the substrate, precise cutting of panels to fit the space, and the use of specialized adhesives and sealants. Attention to detail during installation is paramount, as even small imperfections can lead to moisture intrusion over time. By entrusting the installation to skilled professionals, building owners can ensure that their polyurethane foam insulation panels perform optimally as a moisture barrier for years to come.

Conclusion

Polyurethane foam insulation panels represent a significant breakthrough in moisture barrier technology for the construction industry. Their unique chemical composition, advanced manufacturing techniques, and versatile applications make them an invaluable asset in the fight against moisture-related building issues. By providing superior insulation, energy efficiency, and long-lasting moisture protection, these panels contribute to more durable, comfortable, and sustainable buildings.

As the construction industry continues to evolve, the role of innovative materials like polyurethane foam insulation panels becomes increasingly important. Their ability to address multiple challenges simultaneously—from moisture control to energy conservation—positions them as a key component in modern building design and construction practices. For those seeking to enhance their building's performance and protect against moisture-related issues, polyurethane foam insulation panels offer a proven and effective solution.

For more information on polyurethane foam insulation panels and how they can benefit your construction project, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in choosing the right insulation solution for your specific needs.

FAQ

How do polyurethane foam insulation panels compare to traditional insulation materials in terms of moisture resistance?

Polyurethane foam insulation panels offer superior moisture resistance compared to traditional materials due to their closed-cell structure and hydrophobic properties. They provide a more effective barrier against both liquid water and water vapor.

Can polyurethane foam insulation panels be used in both hot and cold climates?

Yes, these panels are versatile and perform well in various climates. Their moisture-blocking properties make them suitable for humid tropical environments, while their excellent insulation capabilities are beneficial in colder regions.

Are polyurethane foam insulation panels environmentally friendly?

Modern polyurethane foam insulation panels are designed with environmental considerations in mind. They contribute to energy efficiency, reducing overall carbon footprints. Many manufacturers also offer panels made with eco-friendly materials and production processes.

References

1. American Chemistry Council. (2022). "Polyurethanes in Building and Construction."

2. U.S. Department of Energy. (2021). "Insulation Materials." Energy Saver.

3. Building Science Corporation. (2020). "Understanding Vapor Barriers."

4. ASTM International. (2021). "ASTM C1289-21 Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board."