- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cost Guide for Polyurethane Foam Insulation Panels

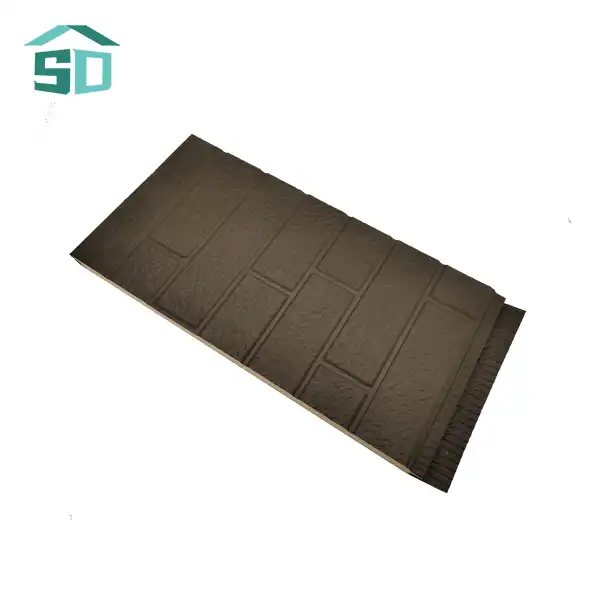

Polyurethane foam insulation panels have become a popular choice for both residential and commercial construction projects due to their exceptional insulating properties and versatility. The cost of these panels typically ranges from $1.50 to $3.50 per square foot, depending on factors such as thickness, density, and quality. For a standard 1,500 square foot home, the total cost for materials and professional installation can range from $2,250 to $5,250. While the initial investment may be higher than traditional insulation methods, the long-term energy savings and increased comfort make polyurethane foam insulation panels a cost-effective solution for many property owners.

Factors Influencing the Cost of Polyurethane Foam Insulation Panels

Panel Thickness and Density

The thickness and density of polyurethane foam insulation panels play a crucial role in determining their cost. Thicker panels with higher density offer superior insulation properties but come at a higher price point. For instance, panels with a thickness of 50mm may cost less than those with 150mm thickness. Similarly, panels with a density of 32 kg/m³ are generally more affordable than those with 40 kg/m³ density. It's essential to strike a balance between insulation performance and budget constraints when selecting the appropriate thickness and density for your project.

Panel Size and Customization

Standard polyurethane foam insulation panels typically come in sizes of 1200mm x 2400mm. However, custom sizes may be available to suit specific project requirements. Customized panels often come at a premium due to the additional manufacturing processes involved. When considering custom sizes, it's crucial to weigh the benefits of a perfect fit against the increased cost. In some cases, using standard-sized panels and cutting them to fit on-site may be a more cost-effective solution.

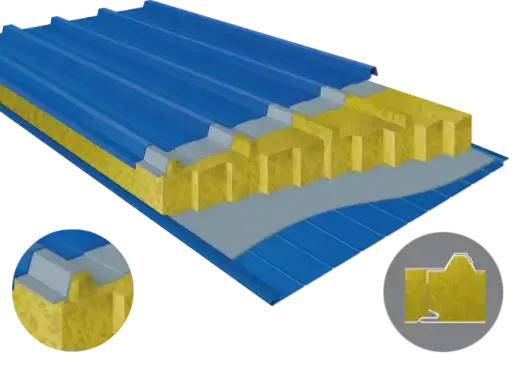

Fire Rating and Thermal Conductivity

Polyurethane foam insulation panels with higher fire ratings and lower thermal conductivity values often command a higher price. Panels with a B1 fire rating, for example, offer excellent fire resistance and may be required in certain building applications. The thermal conductivity of ≤ 0.022 W/(m·K) ensures superior insulation performance, contributing to long-term energy savings. While these high-performance panels may have a higher upfront cost, they can provide significant benefits in terms of safety and energy efficiency over the lifespan of the building.

Installation Costs and Considerations

Professional Installation vs. DIY

The installation of polyurethane foam insulation panels can significantly impact the overall cost of your project. Professional installation ensures proper fitting, sealing, and adherence to building codes. On average, professional installation costs range from $0.50 to $1.50 per square foot, depending on the complexity of the project and local labor rates. While DIY installation may seem like a cost-saving option, it's important to consider the potential risks of improper installation, which can lead to reduced insulation efficiency and potential moisture issues. For most applications, professional installation is recommended to maximize the benefits of polyurethane foam insulation panels.

Preparation and Accessories

Proper preparation of the installation surface and the use of appropriate accessories can affect the overall cost and performance of polyurethane foam insulation panels. Ensuring a clean, dry surface before installation is crucial for optimal adhesion and insulation performance. Additional costs may include adhesives, sealants, and fasteners specifically designed for use with polyurethane foam panels. While these accessories add to the initial cost, they play a vital role in ensuring the longevity and effectiveness of the insulation system.

Project Scope and Complexity

The scope and complexity of your insulation project can significantly influence the overall cost. Factors such as the total area to be insulated, the presence of obstacles or irregular surfaces, and the need for custom cutting or fitting can all impact the final price. For example, insulating a straightforward rectangular room will generally be less expensive than insulating an attic with multiple angles and obstructions. It's advisable to obtain detailed quotes from multiple contractors, taking into account the specific requirements of your project to get an accurate cost estimate.

Long-Term Cost Benefits of Polyurethane Foam Insulation Panels

Energy Savings and Efficiency

While the initial cost of polyurethane foam insulation panels may be higher than traditional insulation materials, the long-term energy savings can be substantial. The exceptional thermal resistance of these panels, with a thermal conductivity of ≤ 0.022 W/(m·K), translates to reduced heating and cooling costs. Over time, these energy savings can offset the higher upfront investment. In fact, studies have shown that buildings insulated with polyurethane foam panels can achieve energy savings of up to 30% compared to those using conventional insulation materials.

Durability and Lifespan

Polyurethane foam insulation panels are known for their durability and longevity. With proper installation and maintenance, these panels can last for over 25 years, maintaining their insulation properties throughout their lifespan. This extended durability means fewer replacements and repairs compared to other insulation materials, resulting in long-term cost savings. Additionally, the moisture and pest-resistant nature of polyurethane foam panels contributes to their longevity, reducing the risk of damage and associated repair costs over time.

Increased Property Value

Investing in high-quality insulation solutions like polyurethane foam panels can increase the overall value of your property. Energy-efficient homes and buildings are increasingly sought after in the real estate market, with buyers willing to pay a premium for properties with lower energy costs and improved comfort. While it's challenging to quantify the exact increase in property value, the combination of energy efficiency, durability, and improved indoor comfort provided by polyurethane foam insulation panels can make your property more attractive to potential buyers or tenants.

Conclusion

Polyurethane foam insulation panels offer a compelling blend of superior insulation performance, durability, and long-term cost benefits. While the initial investment may be higher than traditional insulation methods, the energy savings, increased comfort, and potential property value appreciation make them a wise choice for many construction projects. By carefully considering factors such as panel thickness, density, and installation requirements, property owners can optimize their investment in polyurethane foam insulation panels.

Ready to experience the benefits of polyurethane foam insulation panels for your project? At Weifang Sandong Building Materials Co., Ltd., we offer high-quality, customizable solutions to meet your specific needs. Our panels combine durability, superior insulation, fire resistance, and seamless integration for enhanced performance and aesthetics. Contact us at info@sdqsc.com to learn more about how our polyurethane foam insulation panels can elevate your construction project while providing long-term cost savings.

FAQ

How do polyurethane foam insulation panels compare to other insulation materials in terms of cost?

While polyurethane foam panels may have a higher upfront cost, their superior insulation properties and durability often result in greater long-term savings through reduced energy costs and less frequent replacements.

Are there any additional costs to consider when installing polyurethane foam insulation panels?

Yes, additional costs may include adhesives, sealants, and fasteners. Professional installation is also recommended, which adds to the overall cost but ensures optimal performance.

How long do polyurethane foam insulation panels typically last?

With proper installation and maintenance, these panels can last over 25 years, maintaining their insulation properties throughout their lifespan.

References

1. U.S. Department of Energy. (2021). Insulation Materials.

2. Building Science Corporation. (2020). Guide to Insulating Sheathing.

3. Energy Star. (2022). Methodology for Estimated Energy Savings from Cost-Effective Air Sealing and Insulating.

4. National Association of Home Builders. (2019). What Home Buyers Really Want.