Composition and Manufacturing of PU Insulated Sandwich Panels

Core Material: Polyurethane Foam

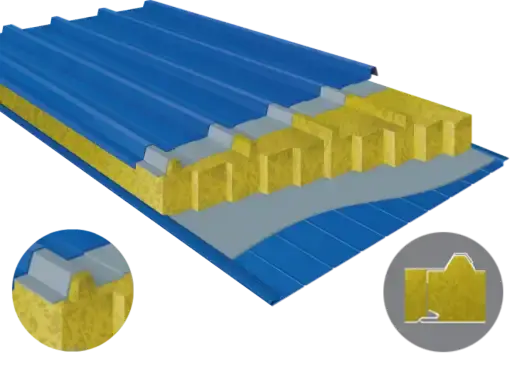

At the heart of PU insulated sandwich panels lies the polyurethane foam core. This remarkable material is created through a chemical reaction between polyol and isocyanate, resulting in a closed-cell structure that traps air within microscopic bubbles. This unique cellular composition is key to the panel's insulative properties, as the trapped air significantly reduces heat transfer.

The manufacturing process of the PU foam core is carefully controlled to ensure consistent density and cell structure throughout the panel. Advanced production techniques allow for precise manipulation of the foam's characteristics, including its thermal conductivity, compressive strength, and fire resistance. This level of control enables PU insulated sandwich panels suppliers to tailor the foam properties to meet specific project requirements.

Metal Facings: Strength and Durability

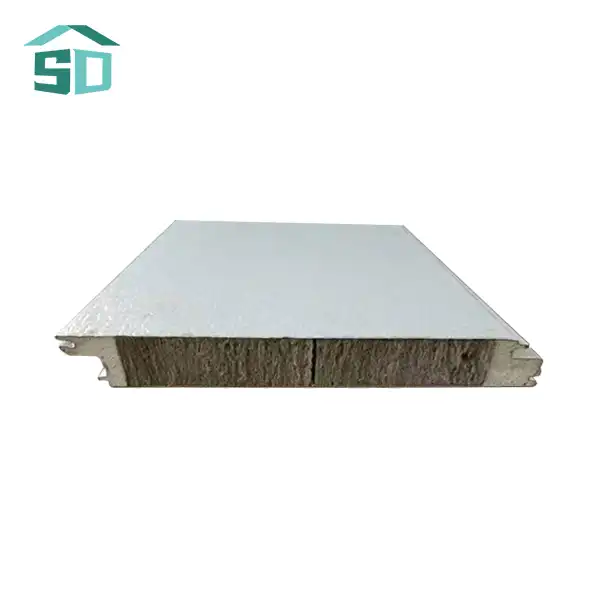

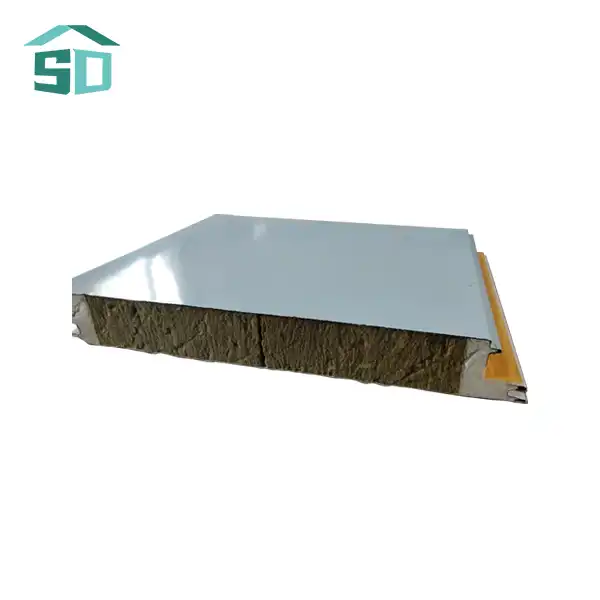

The outer layers of PU insulated sandwich panels typically consist of metal facings, most commonly steel or aluminum. These facings serve multiple purposes, providing structural strength, weather resistance, and an aesthetic finish. The metal sheets are often pre-coated with protective and decorative finishes, enhancing their durability and visual appeal.

The selection of metal facing materials is crucial in determining the overall performance of PU insulated sandwich panels. Factors such as corrosion resistance, tensile strength, and thermal expansion characteristics are carefully considered to ensure the panels can withstand diverse environmental conditions and structural loads.

Bonding Process: Ensuring Panel Integrity

The effectiveness of PU insulated sandwich panels hinges on the strong bond between the foam core and metal facings. This bond is achieved through a sophisticated manufacturing process that involves injecting the liquid polyurethane mixture between the pre-positioned metal sheets. As the foam expands and cures, it adheres firmly to the facings, creating a single, cohesive unit.

Advanced production lines employ precise temperature control and pressure application to optimize the bonding process. This ensures uniform foam distribution and adhesion, eliminating weak points and air pockets that could compromise the panel's performance. The result is a structurally sound panel with excellent load-bearing capacity and resistance to delamination.

Thermal Performance and Energy Efficiency

Insulation Mechanism of PU Foam

The exceptional thermal performance of PU insulated sandwich panels is primarily attributed to the unique properties of the polyurethane foam core. The closed-cell structure of PU foam creates a labyrinth of microscopic air pockets, effectively impeding heat transfer through conduction, convection, and radiation.

The thermal conductivity of PU foam, typically measured in W/mK (watts per meter-kelvin), is remarkably low compared to traditional building materials. This low thermal conductivity translates to a high R-value per inch of thickness, allowing PU insulated sandwich panels to achieve superior insulation with relatively thin profiles. As a result, buildings constructed with these panels can maintain comfortable interior temperatures with reduced energy consumption for heating and cooling.

Impact on Building Energy Efficiency

The implementation of PU insulated sandwich panels in building envelopes can significantly enhance overall energy efficiency. By minimizing heat transfer between the interior and exterior environments, these panels help maintain stable indoor temperatures, reducing the load on HVAC systems. This thermal regulation not only leads to lower energy bills but also contributes to a smaller carbon footprint for the building.

Furthermore, the airtight nature of PU insulated sandwich panels helps prevent air leakage, a common source of energy loss in conventional construction. The seamless integration of these panels creates a continuous insulation barrier, effectively eliminating thermal bridges that can occur at joints and connections in traditional building methods.

Long-term Performance and Durability

The thermal performance of PU insulated sandwich panels is not only impressive but also enduring. Unlike some insulation materials that can degrade or settle over time, the closed-cell structure of PU foam maintains its insulative properties throughout the life of the building. This long-term stability ensures consistent energy efficiency and reduces the need for maintenance or replacement.

Additionally, the metal facings of PU insulated sandwich panels provide protection against moisture intrusion and UV radiation, factors that can compromise the performance of other insulation materials. This durability translates to sustained thermal efficiency and reduced lifecycle costs for building owners.

Structural Properties and Design Flexibility

Load-Bearing Capacity

PU insulated sandwich panels offer remarkable structural performance, owing to their composite nature. The combination of rigid metal facings and a dense foam core creates a panel with high strength-to-weight ratio, capable of withstanding significant loads. This load-bearing capacity allows PU insulated sandwich panels to serve as both insulation and structural elements in many applications.

The structural behavior of these panels is characterized by their ability to resist bending and shear forces. The metal facings act in tension and compression, while the foam core provides shear resistance and prevents local buckling of the facings. This synergistic interaction results in a panel that can span considerable distances without intermediate supports, simplifying construction and reducing material costs.

Architectural Versatility

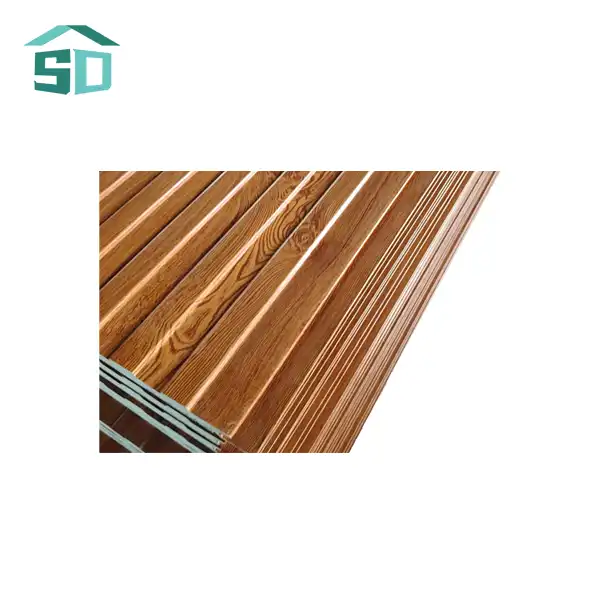

The design flexibility offered by PU insulated sandwich panels is a key factor in their growing popularity among architects and builders. These panels can be manufactured in a wide range of sizes, thicknesses, and profiles to suit various architectural visions and structural requirements. From sleek, modern facades to more traditional aesthetics, PU insulated sandwich panels can be tailored to meet diverse design objectives.

Moreover, the availability of different surface finishes and colors allows for creative expression in building exteriors. PU insulated sandwich panels can be produced with smooth, textured, or embossed surfaces, and can even mimic the appearance of other materials such as wood or stone. This versatility enables architects to achieve their desired aesthetic while benefiting from the superior performance of PU insulated sandwich panels.

Integration with Building Systems

PU insulated sandwich panels are designed for seamless integration with other building components and systems. Their modular nature facilitates rapid installation, reducing construction time and labor costs. Specialized joint systems and accessories ensure weathertight connections between panels, maintaining the building envelope's integrity.

Furthermore, these panels can be easily modified to accommodate windows, doors, and other openings. Advanced manufacturing techniques allow for precise cutting and shaping of panels, enabling complex geometries and custom designs. This adaptability makes PU insulated sandwich panels suitable for a wide range of building types, from industrial facilities to high-end residential projects.

Conclusion

The science behind PU insulated sandwich panels reveals a sophisticated building component that combines advanced materials technology with intelligent design. These panels offer an unparalleled combination of thermal efficiency, structural integrity, and architectural flexibility, making them a cornerstone of modern sustainable construction. As the building industry continues to evolve towards more energy-efficient and environmentally friendly practices, PU insulated sandwich panels stand out as a solution that meets both current needs and future challenges. Their ability to significantly reduce energy consumption while providing durable, versatile building envelopes positions them at the forefront of construction innovation.

For those seeking to elevate their construction projects with state-of-the-art exterior cladding and facade solutions, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of PU insulated sandwich panels and related products. Our commitment to quality and innovation ensures that you receive the best possible solutions for your building needs. To learn more about how our PU insulated sandwich panels can benefit your next project, please contact us at info@sdqsc.com.

FAQs

What are the primary advantages of using PU insulated sandwich panels in construction?

PU insulated sandwich panels offer excellent thermal insulation, structural strength, and design flexibility. They significantly improve energy efficiency, reduce construction time, and provide long-lasting performance.

How do PU insulated sandwich panels compare to traditional insulation methods?

Compared to traditional methods, PU insulated sandwich panels provide superior insulation with less thickness, offer better air tightness, and serve as both insulation and structural elements, simplifying construction processes.

Are PU insulated sandwich panels environmentally friendly?

While the production of PU foam has environmental considerations, the overall lifecycle impact of PU insulated sandwich panels can be positive due to their energy-saving properties and durability, reducing long-term energy consumption and material waste.

References

1. Panjehpour, M., Ali, A. A. A., & Voo, Y. L. (2013). Structural Insulated Panels: Past, Present, and Future. Journal of Engineering, Project, and Production Management, 3(1), 2-8.

2. Mostafa, M., Uddin, N., & Ellingwood, B. R. (2015). Structural performance of thermally insulated composite sandwich panels. Journal of Sandwich Structures & Materials, 17(6), 753-783.

3. Davies, J. M. (2001). Lightweight sandwich construction. John Wiley & Sons.

4. Maleki, M., Shojaee, S., & Seyedpoor, S. M. (2019). Structural reliability analysis of sandwich panels with foam core using finite strip method. Thin-Walled Structures, 143, 106201.

5. Correia, J. R., Garrido, M., Gonilha, J. A., Branco, F. A., & Reis, L. G. (2012). GFRP sandwich panels with PU foam and PP honeycomb cores for civil engineering structural applications: Effects of introducing strengthening ribs. International Journal of Structural Integrity, 3(2), 127-147.

represent a pinnacle of modern construction technology, combining structural integrity with exceptional thermal performance. These innovative building components consist of a polyurethane (PU) foam core sandwiched between two metal facings, typically steel or aluminum. The science behind PU insulated sandwich panels lies in their unique composition and manufacturing process, which results in a lightweight yet robust material with superior insulation properties. By leveraging the low thermal conductivity of PU foam and the strength of metal skins, these panels offer an optimal balance of energy efficiency, durability, and ease of installation, making them a preferred choice for various architectural applications.

represent a pinnacle of modern construction technology, combining structural integrity with exceptional thermal performance. These innovative building components consist of a polyurethane (PU) foam core sandwiched between two metal facings, typically steel or aluminum. The science behind PU insulated sandwich panels lies in their unique composition and manufacturing process, which results in a lightweight yet robust material with superior insulation properties. By leveraging the low thermal conductivity of PU foam and the strength of metal skins, these panels offer an optimal balance of energy efficiency, durability, and ease of installation, making them a preferred choice for various architectural applications.