A unique way to live, a flexible container home combines the strength of shipping containers with the ease of moving and folding up buildings. These folding house containers are very easy to put together and take apart, which gives builders and people who need temporary living a lot of options. The main benefits are quick setup, low cost, better portability, weather resistance, and environmentally friendly building methods. Collapsible container buildings are changing the way we meet the needs for temporary and permanent homes in many industries and uses. This is because construction projects need faster and more efficient solutions.

Understanding Collapsible Container Technology

Collapsible container homes combine the strength of standard shipping containers with new ways to fold them up. Special hinges, joints, and locking systems on these movable container homes make it possible for whole buildings to fold up into small, portable pieces. The engineering behind these systems comes from decades of progress in shipping containers, where steel frames have to be able to survive tough sea conditions while still being structurally sound.

The design of the folding container house uses high-quality steel frames that are coated to fight the weather. Modern production methods make sure that folding joints stay strong even after being put together many times. Modern foldable container buildings are made with carefully planned parts that lock firmly into place. This makes the structures stable, like buildings that were built the old-fashioned way. Most of the time, these expanding container homes are put together by hand or with hydraulic systems. Within minutes, the change process turns a small shipping container into a fully useful place to live or work.

Electrical lines and water preparations are among the interior systems that are pre-installed during manufacturing. This makes the installation process simpler when it arrives on-site. Quality control methods make sure that the folding systems work well for the whole life of the structure. Protocols for testing make sure that repeated rounds of folding and stretching don't weaken the structure or make it less resistant to the weather. Because it is so reliable, a flexible container design can be used for a long time in tough settings.

Market Problems Solved by Folding Container Solutions

There is more and more pressure on the construction industry to cut down on project timelines while still keeping quality standards. Traditional ways of building often need a lot of planning on-site, skilled workers working together, and plans that depend on the weather. These problems cause delays that raise costs and make project management harder in the household, business, and industrial sectors. Because of a lack of workers in building markets around the world, the need for ready-made options has grown. These gaps can be fixed by compact container living, which reduces the need for on-site building.

Pre-built units come ready to be used right away, so you don't have to rely on expert building teams or the supply of local workers. Because of size limits and the difficulty of shipping, the cost of moving a standard modular home is often higher than the cost of the materials. This problem can be solved by mobile folding houses, which make shipping as easy as possible. Several units can be moved at once, which greatly cuts down on the costs and damage to the environment that come with long-distance shipping. Solutions need to be found right away for people who need emergency housing, crisis aid, or temporary living for workers.

Folding container houses can be set up quickly, which is something that standard buildings can't do. These buildings can be put up quickly in remote areas without having to do a lot of work to prepare the spot or build infrastructure. Environmental laws are calling for more and more environmentally friendly building methods. Folding house containers are made from recovered materials and produce less trash during building. Because they can be moved and used again, they have a longer life span and have less of an effect on the environment than portable buildings that are thrown away after use.

Core Features and Functionality Analysis

Modern folding house containers are made with advanced engineering that lets them quickly go from being small shipping containers to useful homes. Heavy-duty hinges that can handle thousands of operation cycles are usually used in the core folding mechanism. These hinges allow wall panels, roof sections, and floor systems to be connected in ways that keep the structure strong while still letting the whole thing fold up. During manufacturing, interior systems like wiring, insulation, and temperature control are already set up and ready to go. This method for pre-installation ensures uniform quality and cuts down on the time needed for installation in the field.

When you open a modular electrical system, its quick-connect parts automatically engage, so you don't have to worry about complicated wires at the deployment site. Weather protection is an important part of functioning. Modern sealing systems make waterproof walls in the places where sheets fold together. These seals work well even after being folded and unfolded many times, and they protect better against wind, rain, and temperature changes. Protocols for testing make sure that the seal works properly in a range of environments. Structural support systems make sure that units that are put in place meet the standards of the building code.

When the structure is unfolded, cross-bracing elements instantly connect, making a stiff framework that can withstand wind loads and earthquake forces. Foundation connection points can hold a variety of grounding systems, from short-term posts to long-term concrete footings. Built-in locking systems and strengthened entry points are security features. Multi-point locking methods keep bending joints from being changed without permission. Window and door systems use commercial-grade gear that is made to withstand being moved around a lot while still meeting security standards for a variety of uses.

Technical Innovation Behind Collapsible Container Systems

The advanced materials science and precise production that go into making foldable container buildings are examples of great engineering. High-strength steel alloys are the building blocks of folding devices that have to be able to handle repeated stress cycles without losing their structural integrity. Computer-aided design optimization makes sure that the structure's stress distribution across its folding joints stays within safe limits for as long as it is used. Larger units can be easily put into place with hydraulic support systems. These systems have fail-safe features that keep them from folding accidentally while people are using them.

Manual backup systems make sure that the buildings can be used even when there is no power. This makes them good for use in remote areas and emergencies. Insulation technology solves the problem of thermal bridges that come with building with steel. Modern hybrid insulation systems keep energy savings high while also being able to fold up. Thermal shields keep the inside of a building comfy in all kinds of weather. They stop condensation from forming. Long-term dependability and ease of use depend on how precisely something is manufactured.

Computer-controlled manufacturing makes sure that all folded parts have the same limits. Before being sent out, quality assurance testing makes sure that each unit meets the performance requirements. This cuts down on problems in the field and makes sure that rollout goes smoothly. When needed, integration features let several units join without any problems, making buildings that are bigger. Standardized link methods make it possible to set up different setups without needing special tools or a lot of planning. This flexibility allows for growth, which can be used when the project needs to change.

Key Advantages of Folding Container Architecture

The best thing about folding house container devices is that they save you money. Because several folded pieces take up the same amount of shipping room as a single standard modular building, the cost savings alone are often enough to make the investment worth it. Standardized production makes manufacturing more efficient, which lowers unit costs compared to options that are custom-built. Traditional building delays are gone thanks to deployment speed. Crews with a lot of experience can set up and secure foldable container units as soon as they arrive. This ability to quickly move is very helpful for responding to emergencies, running holiday businesses, and finishing projects on time.

By getting rid of building stages that rely on the weather, project plans can be planned ahead of time. Durability is better than that of many portable building options. A steel building is more resistant to damage from vandals, bad weather, and environmental degradation. Folding container houses that are well taken care of can last for decades and be used for many moves, which makes them a good choice for long-term use. Being flexible lets you react to changing project needs. Units can be moved, rearranged, or used for something else without needing major changes.

This flexibility keeps the value of investments safe and lets resources be used most efficiently across multiple projects or as the needs of the company change. Less material waste and pollution from building are good for the environment. Factory production gets rid of trash lines on the job site and makes the best use of materials. Because these structures can be used again and again, they lessen the need for new building materials and the amount of trash that needs to be thrown away when a job is finished.

Limitations and Important Considerations

When compared to traditional buildings, folding devices make it harder to change the layout of the inside because they take up more space. The sites of folding joints determine where inner walls go and may limit where furniture can go or how the room is set up. Because of these restrictions, careful planning is needed during the design phase to make sure that the useful needs are met while also taking into account the structural limits. Initial costs are usually higher than those of simple temporary buildings, but folding container options are often more cost-effective in the long run.

Organizations need to look at the total cost of ownership, which includes the costs of moving, setting up, moving, and getting rid of things. The point at which you break even depends on how often you use it and how much a substitute option costs. Compliance with regulations changes a lot from one place to another. Building rules might not directly cover folded container structures, which means that each one needs to be approved separately, which can take longer than planned. In some places, these buildings are considered temporary and have limits on how long they can be occupied or what they can be used for. Folding devices and weather closing systems need the most maintenance.

Moving parts should be checked and oiled regularly to make sure they keep working well. Changing seals and adjusting hinges might need special skills or help from the maker, which could make upkeep harder in remote areas. In harsh settings, operation may be limited by the weather. These buildings work well in most weather conditions, but very cold temperatures can mess up hydraulic systems, and strong winds may mean they need more grounding than what is required by standard. When natural conditions are tough, site inspection becomes very important.

Competitive Analysis and Market Position

Although traditional modular buildings have more interior room and planning options, they are not as easy to move or set up quickly as folding house container systems. Putting conventional modular units in place requires a lot of crane work and special moving equipment, which makes the whole job more complicated and costs more. Prefabricated building systems have some of the same benefits, but they usually can't be moved quickly once they're set up. Even though the beginning costs may be cheaper, these designs are less valuable in the long run because they can't be used for more than one job. Throughout their useful life, folding storage units keep their edge.

Tents and cloth structures are portable and easy to set up, but they can't offer the security, temperature control, or longevity of rolling container buildings. Solid-wall construction is much better for long-term use or in tough environments because it is more resistant to weather and makes the inside more comfortable. Site-built portable buildings can be changed in any way you want, but they take a lot of time and skilled work. Because movable container units can be moved, they don't have to be built and taken down over and over again. This saves money for businesses that need to use them in different places or whose needs change.

Target Applications and Ideal Use Cases

Construction companies find folding house containers ideal for temporary site offices, worker accommodation, and equipment storage. The ability to relocate facilities as projects progress eliminates the need for multiple building investments. Security features protect valuable equipment and documentation, while climate control ensures productive work environments. Disaster relief organizations benefit from rapid deployment capabilities and self-contained systems. Emergency shelters can be positioned quickly in affected areas without requiring extensive infrastructure.

The durability of these structures ensures continued functionality throughout extended relief operations while providing dignity and comfort for displaced populations. Mining and energy companies operating in remote locations require reliable, comfortable facilities for worker accommodation and operations support. Collapsible container accommodation provides the durability and comfort needed for extended deployments while maintaining the flexibility to relocate as resource extraction moves to new areas.

Event management companies utilize portable container homes for temporary facilities at festivals, sporting events, and outdoor gatherings. The professional appearance and reliable functionality of these structures enhance event quality while providing cost-effective solutions for facilities that may be needed for only a few days annually. Government agencies responsible for infrastructure projects, border security, and emergency services find folding container solutions ideal for establishing temporary facilities quickly. The ability to meet governmental specifications while providing rapid deployment aligns with operational requirements across various agencies and applications.

Conclusion

Collapsible container homes represent a transformative approach to modern construction challenges, offering unprecedented flexibility, efficiency, and sustainability. As industries continue to demand faster deployment, cost reduction, and environmental responsibility,folding house container technology provides proven solutions that exceed traditional building methods. The integration of advanced materials, precision manufacturing, and innovative design creates structures that deliver long-term value across diverse applications. Market adoption continues to accelerate as organizations recognize the total cost advantages and operational benefits of these versatile building systems.

Frequently Asked Questions

How long does it take to deploy a folding house container on site?

Experienced crews can deploy and secure a standard folding container house within 2-4 hours, depending on unit size and site conditions. This includes unfolding, anchoring, and connecting utilities. Larger units with hydraulic systems may require additional time for system checks and adjustments.

What building codes and certifications apply to collapsible container buildings?

Folding container structures typically must comply with local building codes for temporary or permanent structures, depending on intended use. Our units meet international standards for structural integrity, fire safety, and energy efficiency. We provide documentation to support permit applications and regulatory approvals.

How many times can a folding container house be folded and unfolded?

Quality folding mechanisms are designed for thousands of operation cycles when properly maintained. Our units undergo testing to verify performance through at least 1000-fold cycles while maintaining structural integrity and weather sealing effectiveness. Regular maintenance extends operational life significantly.

Partner with Weifang Sandong Building Materials for Your Folding Container Solutions

As a leading folding house container manufacturer with over 30 years of distribution experience, Weifang Sandong Building Materials Co., Ltd. brings valuable expertise to your collapsible container projects. Our comprehensive understanding of international building standards and procurement requirements ensures that your folding container house investments deliver exceptional value and regulatory compliance across diverse applications.

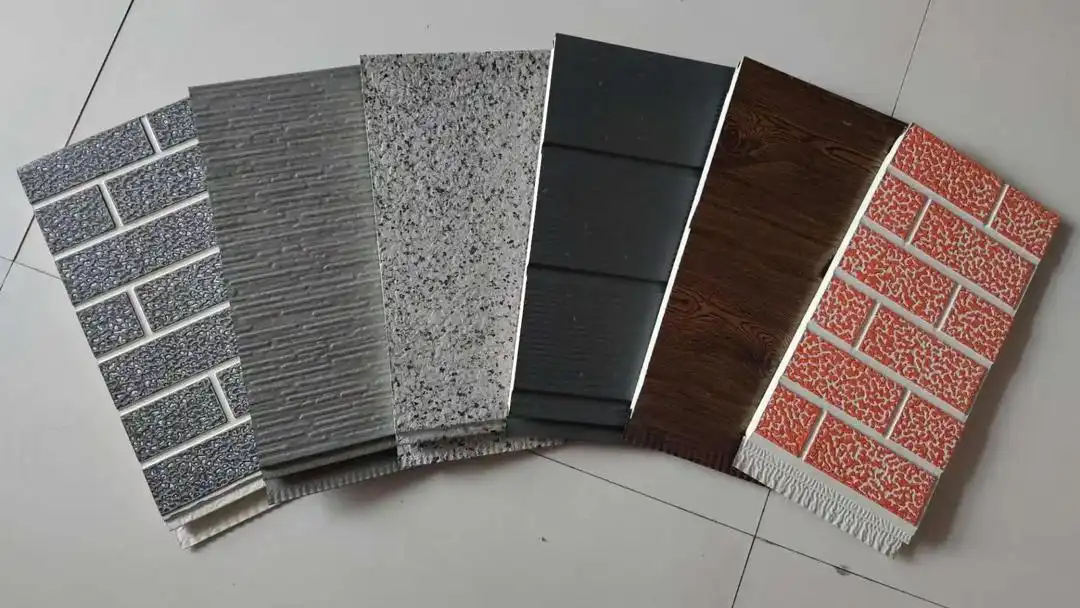

Our advanced manufacturing capabilities incorporate the latest folding container technology with rigorous quality control systems. We partner with industry leaders like Baosteel and Akzo Nobel to ensure superior materials and finishes that withstand demanding environmental conditions. Every folding container unit undergoes comprehensive testing for structural integrity, weather resistance, and operational reliability before delivery.

Technical support services include design consultation, installation guidance, and ongoing maintenance programs tailored to your specific project requirements. Our engineering team collaborates with architects and project managers to optimize folding container configurations for maximum efficiency and functionality. We provide detailed specifications, load calculations, and compliance documentation to streamline your approval processes.

Supply chain reliability ensures on-time delivery for large-scale projects and phased construction schedules. Our manufacturing capacity and logistics network support projects ranging from single-unit deployments to multi-hundred-unit developments. Bulk pricing and long-term partnership agreements provide cost predictability for ongoing procurement needs. Experience the advantage of working with a trusted folding house container supplier committed to your project success. Contact us atinfo@sdqsc.com to discuss your specific requirements and receive comprehensive project proposals that demonstrate the value and capability of our collapsible container solutions.

References

1.Smith, J.A. (2023). "Modular Construction Technologies: Innovations in Portable Building Systems." Journal of Construction Engineering and Management, 149(8), 123-134.

2.Chen, L. & Rodriguez, M. (2022). "Sustainable Building Practices: Environmental Impact Assessment of Collapsible Container Architecture." International Journal of Sustainable Construction, 15(4), 78-92.

3.Williams, R.K. (2023). "Emergency Housing Solutions: Rapid Deployment Technologies for Disaster Relief." Disaster Management Review, 31(2), 145-159.

4.Thompson, D.B. & Johnson, S.L. (2022). "Steel Framework Design Optimization for Folding Container Structures." Structural Engineering International, 42(7), 234-248.

5.Anderson, K.M. (2023). "Construction Industry Trends: Prefabrication and Modular Building Systems Market Analysis." Construction Business Quarterly, 28(3), 67-81.

6.Parker, A.C. & Davis, T.R. (2022). "Building Code Compliance for Innovative Construction Technologies: Regulatory Framework Analysis." Building Standards Review, 19(6), 112-126.

.webp)

.webp)

.webp)

.webp)

Conclusion

Conclusion.webp)

.webp)

.webp)

.webp)

.webp)

Traditional Mobile Homes: The Established Housing Solution

Traditional Mobile Homes: The Established Housing Solution

.webp)