The Versatility of Aluminum Sandwich Panels in Modern Architecture

Aluminum sandwich panels have become a cornerstone in contemporary architecture, offering a perfect blend of form and function. These panels provide architects and builders with a canvas for creativity while ensuring superior performance in various environmental conditions.

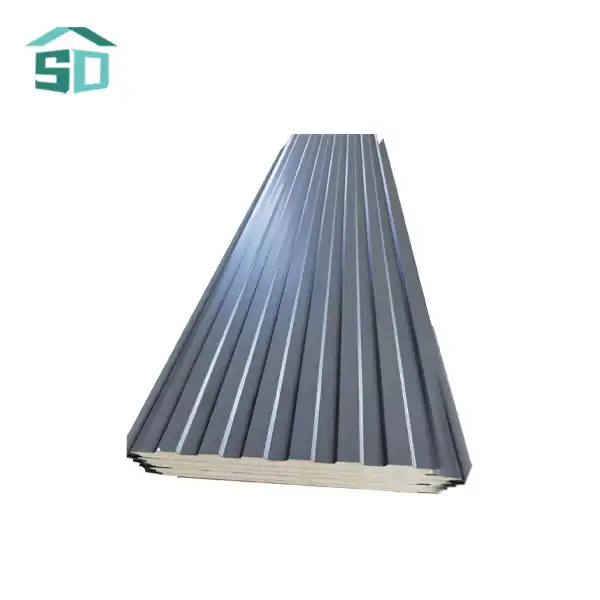

Transforming Building Facades

One of the most widely recognized uses of aluminum sandwich panels is in modern building facades. Their lightweight construction allows for quick and efficient installation, significantly reducing on-site labor and construction time. These panels can be customized with an extensive range of colors, textures, and surface finishes, enabling architects to fully realize their design vision. From streamlined commercial towers to artistic residential developments, they deliver both aesthetics and performance.

Interior Design Solutions

Beyond their striking exterior applications, aluminum sandwich panels are increasingly being used in interior architecture. Their flexibility and ease of installation make them ideal for constructing elegant partition walls, sound-absorbing ceilings, and creative decorative accents. These panels contribute not only to visual appeal but also to acoustic comfort, making them particularly suitable for offices, meeting rooms, hospitals, and libraries where noise control and aesthetics must go hand in hand.

Sustainable Building Practices

As sustainability becomes a driving force in architecture, aluminum sandwich panels have emerged as a key component of green construction strategies. Manufactured using recyclable materials, they help reduce environmental impact throughout the building lifecycle. Their excellent thermal insulation lowers energy consumption by minimizing heat loss or gain, which contributes to reduced HVAC demand and lower utility bills. Their durability also means fewer replacements, supporting long-term environmental responsibility.

Advanced Applications in Transportation and Aerospace

The unique properties of aluminum sandwich panels make them invaluable in the transportation and aerospace industries, where weight reduction and structural integrity are paramount.

Automotive Innovation

In the automotive industry, aluminum sandwich panels are revolutionizing vehicle design by enabling lightweight, durable, and safe structural solutions. When integrated into car bodies, floors, and door modules, these panels help improve fuel efficiency and handling. Their impact resistance enhances passenger safety during collisions. Additionally, their ability to dampen vibrations and reduce road noise contributes to a quieter, more comfortable driving experience, aligning with trends in electric and luxury vehicle development.

Aerospace Advancements

Aluminum sandwich panels are extensively used in aerospace engineering, where strength-to-weight ratio is a top priority. They are commonly applied in aircraft cabin interiors, flooring systems, and cargo enclosures. Their high thermal resistance and ability to maintain mechanical stability under extreme conditions make them ideal for use in satellites and spacecraft components. These panels support mission-critical requirements while contributing to fuel efficiency and structural reliability in aviation and space exploration.

Marine Applications

The shipbuilding industry also benefits from the integration of aluminum sandwich panels. Their lightweight nature reduces the vessel’s overall mass, improving speed and fuel economy. Meanwhile, their resistance to corrosion ensures longevity in saltwater environments, minimizing maintenance costs. These panels are frequently used in the construction of decks, walls, and superstructures, helping shipbuilders achieve better performance metrics while meeting strict marine safety standards and sustainability goals.

Innovations in Manufacturing and Customization

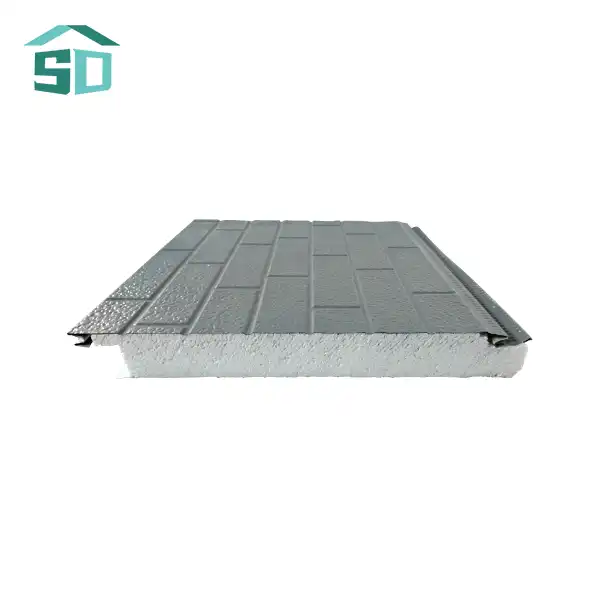

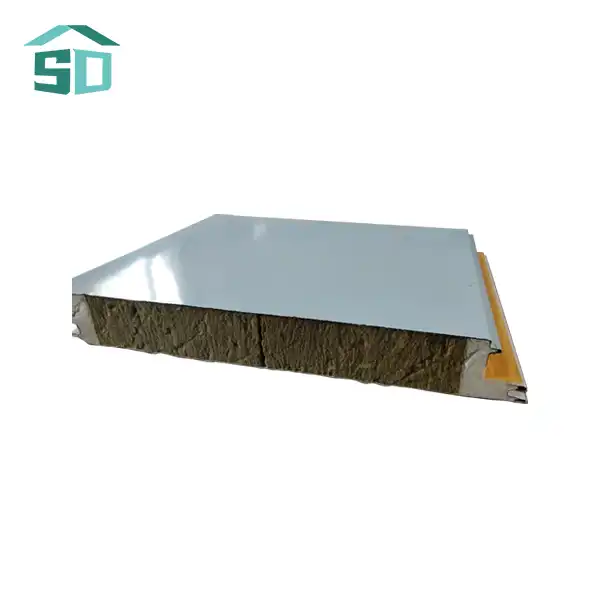

The manufacturing process of aluminum sandwich panels has seen significant advancements, leading to improved quality, consistency, and customization options.

Advanced Production Techniques

Modern production facilities employ cutting-edge techniques such as automated lamination, high-speed curing, and computer-controlled calibration to achieve consistent panel quality. These processes guarantee optimal adhesion between aluminum skins and the core material, improving mechanical stability and dimensional accuracy. Additionally, integrated quality control systems test each panel for fire performance, compressive strength, and surface finish, ensuring reliability and compliance with stringent industry standards.

Customization Capabilities

Leading manufacturers like Weifang Sandong Building Materials Co., Ltd. provide extensive customization services to meet the demands of diverse applications. Clients can specify panel thicknesses ranging from 20mm to 150mm, as well as custom lengths, widths, textures, and color options. This high degree of flexibility ensures that each panel aligns perfectly with architectural and functional goals, whether for compact renovations, expansive commercial buildings, or demanding industrial installations.

Continuing Research and Development

The aluminum sandwich panel industry continues to evolve through dedicated research and development. Efforts are focused on exploring new core materials such as eco-friendly foams and advanced honeycombs, improving fire retardancy, and boosting impact resistance. These innovations aim to expand the scope of panel applications across sectors such as renewable energy, smart infrastructure, and modular construction, promising even broader adoption in future-forward, sustainable building solutions.

Conclusion

Aluminum sandwich panels have proven to be a game-changer in various industries, offering a unique combination of strength, lightness, and versatility. From transforming architectural landscapes to enabling advancements in transportation and aerospace, these panels continue to push the boundaries of what's possible in design and engineering.

As technology advances and sustainability becomes increasingly important, the role of aluminum sandwich panels is likely to grow even more significant. For those interested in exploring the possibilities of aluminum sandwich panels for their projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and customized solutions. To learn more about their range of exterior cladding and facade solutions, contact them at info@sdqsc.com.