Resort developers and construction professionals increasingly turn to expandable modular house solutions to meet growing accommodation demands while maintaining flexibility and cost control. These innovative housing systems offer unprecedented scalability for hospitality projects, allowing properties to adapt capacity based on seasonal fluctuations and market demands. Modern expandable modular homes combine sophisticated design aesthetics with practical functionality, delivering guests comfortable experiences while providing resort operators with efficient space management solutions. This comprehensive guide explores essential considerations for procurement teams, project managers, and design directors evaluating modular accommodation systems for resort developments.

Understanding Expandable Modular Construction Technology

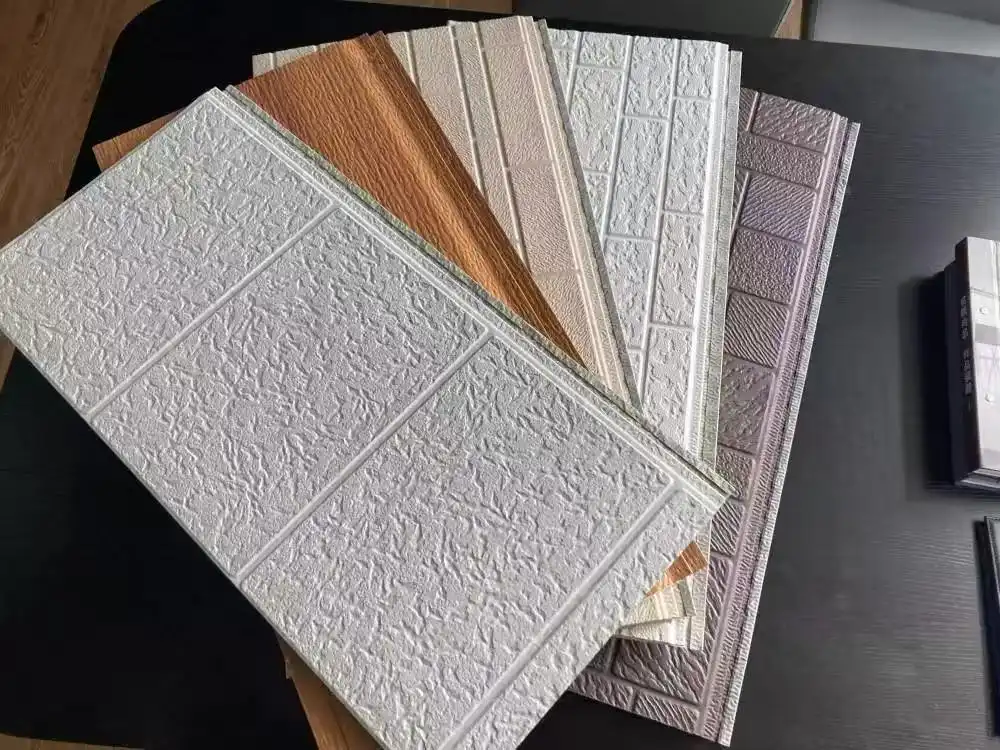

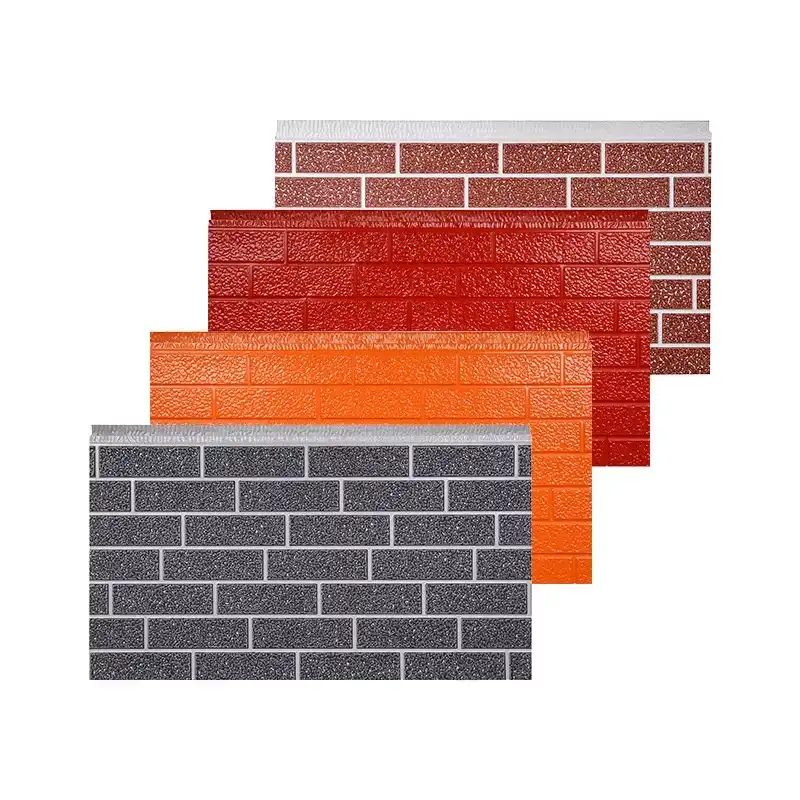

Expandable modular house technology is a big step forward in the way manufactured homes are built. The parts in these systems are precisely designed and made in controlled factories, which guarantees uniform quality and shortens the time it takes to install them. The flexible feature lets each unit take up more room by using movable walls, fold-out sections, or connecting pieces that add extra living space without any problems. Modern modular design uses elements that are both light and strong, like composite panels, steel frame systems, and new insulating technologies.

With smart home integration, resort managers can keep an eye on and change weather systems from afar, making all of the units more energy efficient. Because these buildings are movable, they can be put up temporarily or for the season without making permanent changes to the spot. A lot of the new ideas in this field come from using sustainable building methods. To meet today's environmental standards, manufacturers use materials that are good for the earth and parts that use less energy. Quick building methods keep construction from getting in the way of vacation operations, so properties can add more rooms without having to close for long periods of time.

Key Specifications and Design Considerations

Effective, adaptable modular homes for vacation use are made with space-saving design principles in mind. When small, units usually take up between 300 and 800 square feet of space. When fully spread, they can cover 50 to 100 percent more space. Customizable plans let developers choose how bedrooms, bathrooms, and shared areas are set up so that they appeal to a wide range of guests. Insulated wall systems keep you comfortable in a wide range of climates while also lowering your business's energy costs. Modern units have R-values that are about the same as older buildings because they use advanced panel technologies and strategies to stop thermal bridges.

Choosing long-lasting materials will ensure that they work well for a long time, even in harsh weather and situations where they are used a lot. To keep their structural stability through repeated rounds of expansion and contraction, foldable parts need precise engineering. High-quality hardware systems, like tracks, hinges, and locking mechanisms, are put through a lot of tests to make sure they will work reliably for a long time. The compact living plan makes the best use of the useful room while still meeting the comfort needs of guests.

Procurement Advantages for Resort Development Projects

Mobile home options are very helpful for resort makers who have to deal with tight budgets and complicated project schedules. When compared to traditional on-site building, factory-controlled manufacturing doesn't depend on weather delays or skilled workers. Standardized production processes help phased development strategies by making it possible to accurately predict costs and schedule deliveries. Controlled production settings, where parts are tested thoroughly before being shipped, are good for quality control. This method cuts down on flaws and guarantees claims while making sure that the finish quality is the same on all units.

Applications for temporary housing can help you make extra money during building or special events. One benefit of flexible systems that is often ignored is their ability to help with disaster aid. Resorts in areas that are prone to natural disasters can quickly provide emergency housing for guests who have to leave their homes or rescue workers who are helping. Because they are movable, they can be moved quickly when the weather threatens standard buildings.

Technical Support and Installation Requirements

Expandable modular house systems work best and last the longest when they are installed by a professional. Manufacturers with a lot of experience offer full help, including instructions on how to prepare the site, what the base needs to be like, and how to connect utilities. Technical paperwork includes instructions on how to put things together, when to do maintenance, and how to run the lodge for staff. Compared to regular building jobs, site planning usually doesn't require as much digging.

The most important building needs are level foundations, power lines, and entry roads. By using flexible base systems and different fastening methods, modular design makes it possible to work with difficult ground. Training programs for resort repair teams teach them how to do regular checks, when to lubricate parts, and how to fix problems. To help with day-to-day activities, manufacturers often offer video tools, detailed guides, and online advice services. Sample supply lets decision-makers check the quality of the building and the design features before committing to a large-scale purchase.

Regulatory Compliance and Safety Standards

To follow the building code, you need to pay close attention to the rules in your area that guide both temporary and permanent structures. Most modular makers get the right approvals for their standard designs, which speeds up the process of getting permits for individual projects. Standards for fire protection, structural load, and mobility are different depending on the area and the type of use. Environmental protection laws affect the choice of materials and how trash is handled during the production and placement stages. Using environmentally friendly design features in resorts can help them get green building standards and lower their long-term running costs.

Energy-efficient systems help protect the environment and make guests more comfortable at the same time. Checking the safety of a structure means checking all of its parts, including its connections, its ability to withstand weather, and, if necessary, its ability to withstand earthquakes. Third-party licenses give buying teams more confidence when they are looking at the skills of suppliers. Usually, documentation packages have technical reports, test results, and certificates of compliance that need to be sent to regulators.

Cost Analysis and Return on Investment

Modular building offers affordable living options that make vacation development projects very profitable, especially with an expandable modular house design. Depending on the level of specifications and the state of the site, the initial capital costs are usually 20 to 40 percent less than those for a similar standard building. Cutting down on building times speeds up the time it takes to make money, which makes project return estimates better. Some operational cost benefits are fewer repairs that need to be done, better energy economy, and the ability to handle capacity in a fluid way.

Being able to move or rearrange units protects assets against changing market conditions or plans for growth. Because they are movable and built to a normal level, resale prices stay high. The ability of flexible systems to react to changing guest tastes and market needs leads to long-term financial gains. Without spending a lot of money on building, properties can improve individual rooms, change plans, or move accommodations. This adaptability gives you an edge in hotel markets that are always changing.

Supplier Evaluation Criteria

To do a good job of buying, you need to carefully evaluate possible providers based on their professional skills, level of service, and project experience. A manufacturing capacity study makes sure that providers can meet the needs of the project within the time limits that have been set. Verification of quality control methods gives customers trust in the consistent arrival of goods for big orders. Suppliers' project profiles show that they have worked on similar hotel projects and know how to deal with difficult site circumstances. Case studies show how well the company can solve problems and provide help after the work is complete.

Client recommendations can tell you a lot about a supplier's long-term relationships and how reliable their service is. The paperwork for certification includes information about safety rules, environmental management systems, and industry standards that apply. A financial stability review makes sure that the source will be able to keep its promises about guarantees and assistance throughout the lifecycle of the product. As part of technical support, you can get help with planning, installation, and training for upkeep.

Conclusion

Expandable Modular House represents a transformative solution for resort developers seeking flexible, cost-effective accommodation strategies. The combination of quick assembly, customizable designs, and sustainable construction practices addresses key challenges in modern hospitality development. Successful implementation requires careful supplier selection, thorough technical planning, and attention to regulatory compliance requirements. The investment in quality modular systems delivers long-term value through operational flexibility, reduced maintenance costs, and enhanced guest satisfaction. As the hospitality industry continues evolving toward more sustainable and adaptable accommodation models, expandable modular construction provides the foundation for future resort success.

Partner with Weifang Sandong Building Materials for Expandable Modular House Solutions

Weifang Sandong Building Materials Co., Ltd. has a lot of experience with external siding and wall options that work great for expandable modular homes. Our wide range of products includes insulated sandwich wall panels, light gauge steel frames, and advanced covering systems that make modular vacation rooms look better and work better. With relationships with manufacturing giants like Baosteel and Akzo Nobel, we can provide high-quality products that meet the strict needs of hotel projects. Over 30 countries are part of our global service network, which helps foreign resort-building projects with local support.

Advanced quality control methods make sure that materials work the same way on big orders, and our experienced technical team helps with design planning and installation in a way that fits the needs of modular building. Our skills as an expanding modular house provider help you complete your project successfully, whether it's building a new lodge or adding on to an existing one. Ready to explore how our building materials can enhance your resort's modular housing project? Contact our technical specialists to discuss your specific requirements and schedule a consultation. Reach out to us at info@sdqsc.com to begin planning your next resort expansion with confidence.

References

1. Johnson, M. "Modular Construction in Hospitality: Design and Implementation Guidelines." International Journal of Construction Management, Vol. 15, 2023.

2. Chen, L. and Rodriguez, A. "Sustainable Building Materials for Resort Development: A Comprehensive Analysis." Green Building Review, Issue 42, 2024.

3. Thompson, K. "Expandable Housing Systems: Engineering Principles and Applications." Modern Construction Technology Quarterly, Spring 2023.

4. Williams, S. "Cost-Benefit Analysis of Modular vs. Traditional Construction in Commercial Projects." Construction Economics Today, Vol. 28, 2024.

5. Park, J. "Fire Safety and Building Code Compliance for Modular Structures." Safety Engineering International, Issue 156, 2023.

6. Davis, R. "Smart Integration Technologies for Modern Modular Buildings." Building Automation Review, Vol. 34, 2024.

(1).webp)

.webp)

.webp)

.webp)