Comprehending the Water-Resistant Properties of Polyurethane Insulation Panels

Polyurethane insulation panels are renowned for their superior insulation capabilities, but their water-resistant qualities are equally impressive. The unique composition of these panels contributes to their ability to withstand moisture and protect buildings from water-related issues.

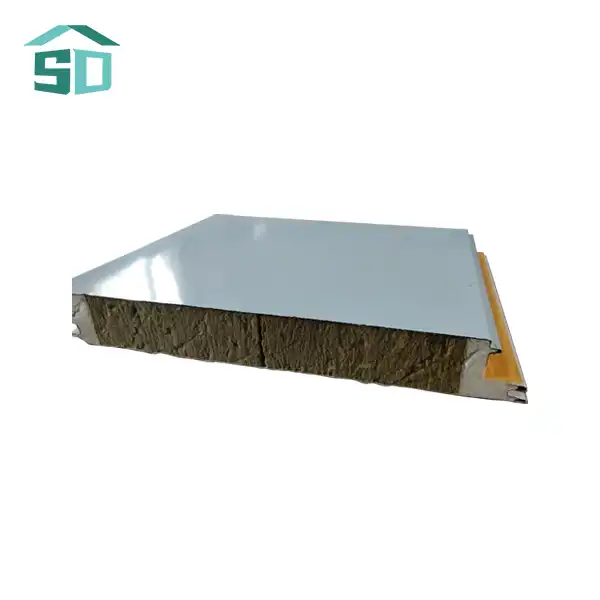

Closed-Cell Structure: The Key to Moisture Resistance

The secret behind the water-resistant nature of polyurethane insulation panels lies in their closed-cell structure. This microscopic arrangement of cells creates a dense, compact material that significantly impedes water penetration. Unlike open-cell foams, closed-cell polyurethane has minimal interconnected air spaces, leaving little room for water molecules to travel through the material.

This structural advantage translates into practical benefits for building insulation. When exposed to moisture, polyurethane panels absorb only a fraction of water compared to other insulation materials. This low water absorption rate helps maintain the panel's thermal performance and structural integrity, even in damp environments.

Vapor Barrier Properties

In addition to resisting liquid water, polyurethane insulation panels also act as an effective vapor barrier. This characteristic is crucial in controlling moisture movement within building envelopes. By limiting vapor transmission, these panels help prevent condensation issues that can lead to mold growth, wood rot, and deterioration of building materials.

The vapor barrier properties of polyurethane panels are particularly beneficial in climates with significant temperature differentials between indoor and outdoor environments. They help maintain a consistent indoor humidity level, contributing to a healthier and more comfortable living or working space.

Advantages of Water-Resistant Polyurethane Insulation Panels

The water-resistant nature of polyurethane insulation panels offers numerous advantages for both residential and commercial applications. These benefits extend beyond mere moisture protection, encompassing energy efficiency, durability, and overall building performance.

Enhanced Thermal Performance

One of the primary advantages of water-resistant polyurethane panels is their ability to maintain thermal performance even when exposed to moisture. Unlike some insulation materials that can lose their insulating properties when damp, polyurethane retains its excellent R-value. This consistent thermal resistance translates to more stable indoor temperatures and reduced energy consumption for heating and cooling.

The thermal conductivity of polyurethane insulation panels, typically around 0.022 W/mK, remains largely unaffected by environmental moisture. This stability ensures that buildings insulated with these panels continue to benefit from energy savings year-round, regardless of weather conditions.

Longevity and Durability

The water-resistant properties of polyurethane insulation panels contribute significantly to their longevity. By repelling moisture and preventing water absorption, these panels are less susceptible to degradation caused by water damage. This resistance to moisture-related issues such as mold growth, corrosion, and material breakdown means that polyurethane panels can maintain their effectiveness for many years, often outlasting other insulation materials.

The durability of these panels is further enhanced by their resistance to settling and compaction. Unlike some insulation materials that can sag or settle over time, especially when exposed to moisture, polyurethane panels maintain their shape and thickness. This dimensional stability ensures consistent insulation performance throughout the lifespan of the building.

Versatility in Application

The water-resistant nature of polyurethane insulation panels makes them versatile enough for use in various parts of a building, including areas prone to moisture exposure. They are suitable for exterior walls, roofs, and even below-grade applications where moisture management is critical.

In coastal areas or regions with high humidity, these panels prove particularly valuable. Their ability to withstand moisture while providing excellent insulation makes them an ideal choice for buildings exposed to challenging environmental conditions. The panels' adaptability is further enhanced by their availability in various thicknesses (typically 50mm, 75mm, 100mm, with custom options available) and sizes (standard 1200 x 2400 mm, with custom sizes possible), allowing for tailored solutions to specific insulation needs.

Best Practices for Maximizing Water Resistance in Polyurethane Insulation Panels

While polyurethane insulation panels offer inherent water-resistant properties, proper installation and maintenance are crucial to maximize their effectiveness in moisture management. Adhering to best practices ensures that these panels provide optimal protection against water infiltration and related issues.

Proper Installation Techniques

The installation process plays a vital role in enhancing the water-resistant capabilities of polyurethane insulation panels. Proper installation begins with thorough preparation of the surface, ensuring it is clean, dry, and free from any debris or contaminants that could compromise the panel's adhesion.

When cutting panels to size, it's essential to use appropriate tools that create clean, precise edges. This precision helps prevent gaps or irregularities that could allow water ingress. Applying a high-quality adhesive or using mechanical fasteners as per project requirements ensures a secure attachment to the substrate.

One of the most critical steps in installation is sealing the joints between panels. Using high-quality tape or sealant specifically designed for polyurethane panels creates an additional barrier against moisture infiltration. This step is crucial in maintaining the continuity of the water-resistant layer across the entire insulated surface.

Integration with Building Envelope Systems

To maximize the water-resistant properties of polyurethane insulation panels, it's essential to consider their integration with other elements of the building envelope. This includes proper flashing around openings, adequate drainage systems, and appropriate vapor barriers where necessary.

In wall applications, for instance, the panels should be integrated with the building's water management system, including properly installed weather barriers and flashing. For roof applications, ensuring proper overlap and integration with roofing membranes is crucial to prevent water ingress at panel joints or edges.

By considering the polyurethane panels as part of a comprehensive moisture management strategy, builders and architects can create a more resilient and durable building envelope that effectively resists water infiltration and related issues.

Regular Inspection and Maintenance

While polyurethane insulation panels are known for their durability and longevity, regular inspection and maintenance can help ensure their continued effectiveness in resisting water. Periodic checks for any signs of damage, such as cracks, gaps, or areas where sealant may have deteriorated, can prevent minor issues from escalating into significant problems.

In the event of damage, prompt repairs using compatible materials are essential. This might involve resealing joints, replacing damaged sections, or addressing any issues in the surrounding building envelope that could compromise the panels' water-resistant properties.

By implementing these best practices, building owners and managers can maximize the water-resistant capabilities of polyurethane insulation panels, ensuring long-term protection against moisture-related issues and maintaining the panels' excellent insulation performance.

Conclusion

Polyurethane insulation panels offer a robust solution for moisture management in building envelopes. While not completely waterproof, their excellent water-resistant properties, combined with proper installation and maintenance, provide effective protection against water infiltration and related issues. The panels' ability to maintain thermal performance in the face of moisture exposure, coupled with their durability and versatility, makes them an invaluable asset in modern construction.

As the construction industry continues to prioritize energy efficiency and building durability, the role of water-resistant insulation materials like polyurethane panels becomes increasingly significant. By understanding and leveraging the unique properties of these panels, architects, builders, and property owners can create more resilient, comfortable, and energy-efficient structures.

For more information about polyurethane insulation panels and other exterior cladding solutions, please contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is committed to providing high-quality products and expert guidance to meet your building insulation needs.