Grasping the Composition and Properties of PU Insulation Panels

The Science Behind PU Insulation

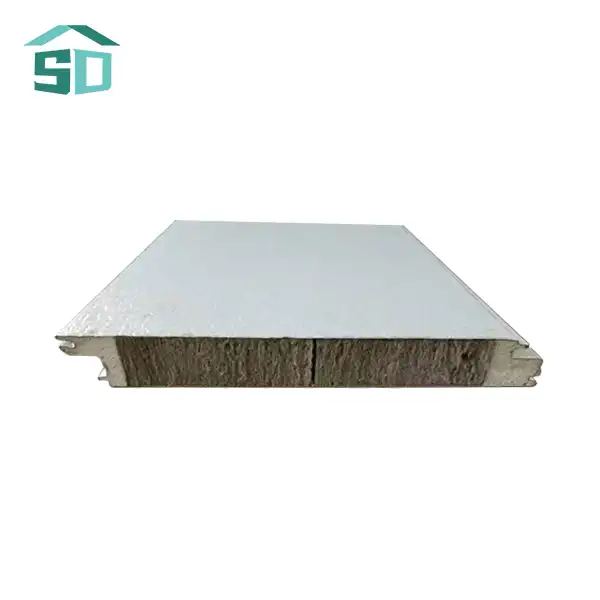

PU cover boards are created from polyurethane, a flexible polymer known for its uncommon protection properties. The fabricating handle includes the response of polyols and diisocyanates, coming about in a closed-cell froth structure that traps discuss inside little bubbles. This one of a kind composition gives PU boards their exceptional warm resistance and lightweight nature.

The closed-cell structure of PU insulation panels contributes to their impressive thermal conductivity of 0.018W/m.k. This low thermal conductivity translates to a high R-value, ensuring optimal thermal performance in various climates. The panels keep buildings warmer in winter and cooler in summer, significantly reducing energy consumption and costs associated with heating and cooling.

Key Properties of PU Insulation Panels

PU insulation panels boast a range of properties that make them stand out in the construction industry:

- Thermal Resistance: With a thermal resistance of 2.09m2k/w, PU panels provide unmatched insulation performance.

- Fire Resistance: Achieving a fire-protection rating of B1/B2, these panels enhance building safety.

- Moisture Resistance: A waterproof rate of 0.0008 ensures excellent protection against moisture intrusion.

- Structural Integrity: The panels exhibit high compressive strength of 52.7kpa, contributing to their durability.

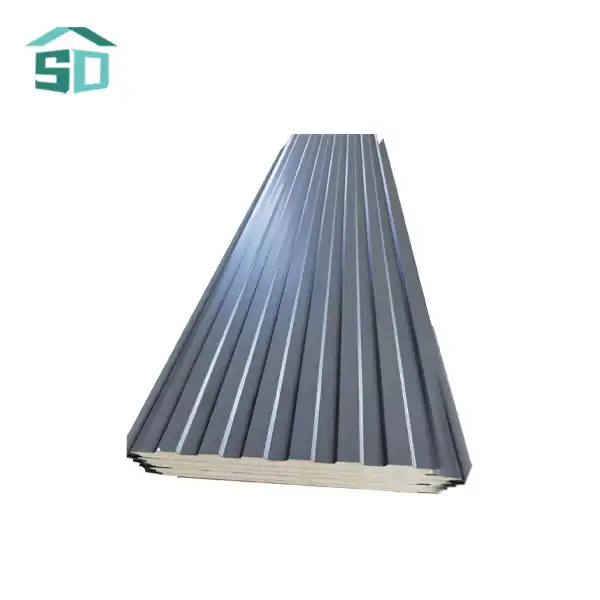

- Wind Resistance: With a wind resistance of 8.0 Kpa, PU panels are suitable for various weather conditions.

These properties make PU insulation panels an ideal choice for both interior and exterior applications, offering a balance of performance and versatility.

Advantages of PU Insulation Panels in Construction

Energy Efficiency and Cost Savings

One of the primary advantages of PU insulation panels is their ability to significantly enhance energy efficiency in buildings. The superior thermal insulation properties of these panels create an effective barrier against heat transfer, reducing the workload on HVAC systems. This translates to lower energy consumption and substantial cost savings for building owners and occupants over time.

The energy-saving potential of PU insulation panels is particularly notable in extreme climates, where maintaining comfortable indoor temperatures can be challenging and expensive. By minimizing heat loss in winter and heat gain in summer, these panels contribute to a more stable and comfortable indoor environment while reducing the carbon footprint of buildings.

Versatility and Customization

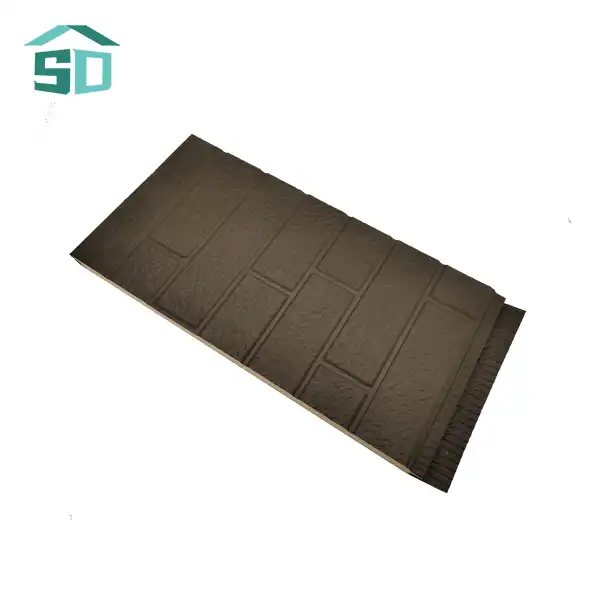

PU insulation panels offer remarkable versatility in terms of application and customization. They are suitable for both interior and exterior wall insulation, making them a versatile solution for various construction projects. The panels can be tailored to meet specific project requirements, with customizable lengths and thicknesses to suit different applications.

For outside utilize, PU boards are accessible in thicknesses of 16mm or 20mm, with a width of 383mm. Insides applications ordinarily utilize 10mm thick boards with a width of 450mm. This adaptability permits modelers and builders to optimize separator execution whereas following to spatial imperatives and plan necessities.

Moreover, PU insulation panels can be finished with a variety of surface materials, ranging from 0.23mm to 0.27mm in thickness. This customization extends to colors and designs, enabling seamless integration with various architectural styles and aesthetic preferences.

Installation and Maintenance of PU Insulation Panels

Effortless Installation Process

The installation of PU insulation panels is a straightforward process that requires minimal specialized tools and labor. This ease of installation contributes to cost-effectiveness and reduced project timelines. The general installation process involves the following steps:

1.Surface Preparation:Ensure the substrate is clean, dry, and free from any debris or contaminants.

2.Panel Cutting:If necessary, measure and cut the panels to fit the specific dimensions of the installation area.

3.Fixing:Secure the panels using appropriate fasteners and adhesives, following manufacturer recommendations for the specific application.

4.Sealing:Apply compatible sealants to joints and edges to enhance insulation performance and moisture resistance.

The lightweight nature of PU insulation panels further simplifies the installation process, reducing the physical strain on workers and minimizing the risk of structural stress on the building.

Long-Term Durability and Maintenance

PU cover boards are built for long-term execution with negligible support prerequisites. Their resistance to weathering, erosion, and UV harm guarantees maintained execution indeed in challenging natural conditions. The panels' dampness resistance too avoids the development of form and mold, contributing to more beneficial indoor discuss quality and decreased support needs.

To maintain optimal performance, periodic visual inspections are recommended to check for any signs of damage or wear. In most cases, simple cleaning with mild detergent and water is sufficient to keep the panels in good condition. The durability of PU insulation panels translates to lower lifecycle costs and extended periods between replacements, making them a cost-effective choice for long-term building performance.

Conclusion

PU insulation panels offer a superior solution for both interior and exterior wall insulation, combining exceptional thermal performance with versatility and ease of use. Their energy efficiency, customization options, and long-term durability make them an ideal choice for modern construction projects focused on sustainability and performance.

As the construction industry continues to evolve towards more energy-efficient and sustainable practices, PU insulation panels are poised to play a crucial role in shaping the future of building insulation. Their ability to meet diverse project requirements while delivering outstanding thermal performance positions them as a top choice for architects, builders, and property owners alike.

For more information about PU insulation panels and how they can benefit your construction project, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.