The Science Behind Polyurethane Insulation Panels

Composition and Manufacturing Process

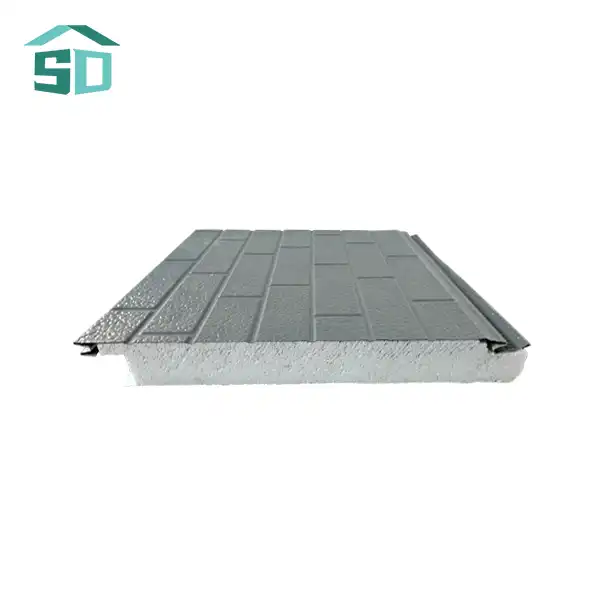

Polyurethane insulation panels are crafted using a sophisticated blend of chemicals and advanced manufacturing techniques. The core material, polyurethane foam, is created through a reaction between polyol and isocyanate, with added blowing agents to form the characteristic cellular structure. This process results in a rigid foam with exceptional insulative properties.

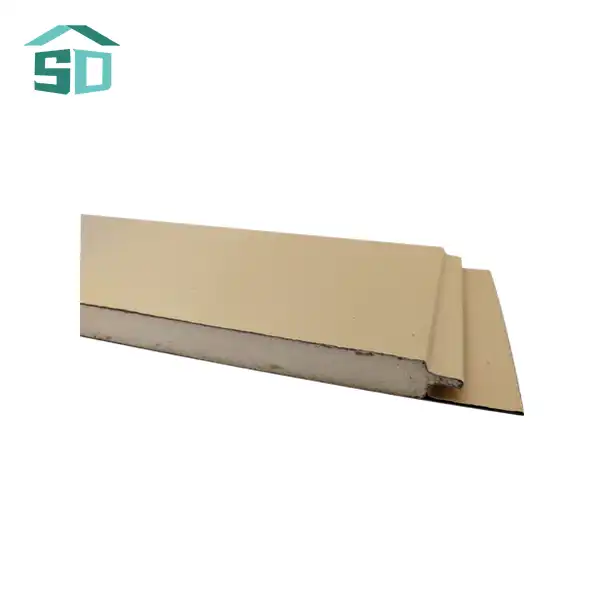

During production, the foam is sandwiched between two facing materials, typically metal or other durable substrates. The company's state-of-the-art production lines ensure precise control over the foam's density, thickness, and overall quality. Rigorous testing of raw materials, including steel coils and aluminum foil, guarantees the panels meet stringent performance standards.

Thermal Conductivity and R-Value

One of the most compelling traits of polyurethane cover boards is their astoundingly moo warm conductivity. With a warm conductivity esteem of fair 0.022 W/mK, these boards altogether outflank numerous customary separator materials. This moo conductivity interprets to a tall R-value, which measures the material's resistance to warm stream.

The superior R-value of polyurethane insulation panels allows for effective temperature regulation with thinner material layers. This characteristic is particularly advantageous in scenarios where space is at a premium, such as in retrofitting projects or modern, streamlined architectural designs.

Moisture Resistance and Vapor Barrier Properties

Beyond thermal insulation, polyurethane panels excel in moisture management. The closed-cell structure of the foam creates an inherent barrier against water vapor, preventing moisture infiltration and potential issues like mold growth or structural damage. This moisture resistance contributes to a healthier indoor environment and extends the longevity of the building envelope.

Advantages of Polyurethane Insulation Panels in Construction

Energy Efficiency and Cost Savings

The primary advantage of polyurethane insulation panels lies in their exceptional energy efficiency. By creating a robust thermal barrier, these panels significantly reduce heat transfer between the interior and exterior of a building. This efficiency translates to tangible cost savings for property owners, as heating and cooling systems operate more effectively and consume less energy.

Over time, the initial investment in high-quality polyurethane insulation panels can lead to substantial returns through reduced energy bills. In an era of increasing energy costs and environmental consciousness, this aspect of polyurethane insulation is particularly appealing to both residential and commercial property owners.

Versatility in Application

Polyurethane separator boards illustrate momentous flexibility over different development ventures. Their application expands from private complexes and workplaces to estates, gardens, and indeed authentic building redesigns. The panels' versatility is assist improved by customization alternatives, counting distinctive thicknesses (50mm, 75mm, 100mm, and custom sizes) and surface medicines (smooth, finished, or coated).

This flexibility allows architects and builders to incorporate polyurethane insulation panels into diverse design schemes, addressing both functional and aesthetic requirements. Whether used in walls, roofs, or ceilings, these panels contribute to the overall performance and visual appeal of the structure.

Durability and Longevity

The durability of polyurethane insulation panels is a significant factor in their growing popularity. These panels maintain their structural integrity and insulative properties over extended periods, even when exposed to challenging environmental conditions. The resistance to degradation ensures that the energy-saving benefits and overall performance of the insulation remain consistent throughout the building's lifecycle.

Furthermore, the panels' lightweight yet robust construction simplifies handling and installation, reducing labor costs and minimizing the risk of damage during the construction process. This combination of durability and ease of use makes polyurethane insulation panels a cost-effective solution in the long term.

Environmental Considerations and Safety Features

Eco-Friendly Aspects of Polyurethane Insulation

As the development industry progressively prioritizes supportability, the eco-friendly characteristics of polyurethane cover boards have come to the cutting edge. By altogether decreasing vitality utilization in buildings, these boards play a vital part in minimizing carbon impressions and supporting worldwide endeavors to combat climate alter.

Modern manufacturing processes for polyurethane insulation panels have also evolved to be more environmentally conscious. Many manufacturers now use eco-friendly blowing agents and recyclable materials in their production, further enhancing the sustainability profile of these products.

Fire Safety and Compliance

Safety is paramount in construction, and polyurethane insulation panels address this concern through their fire-resistant properties. Achieving a Class B2 (non-combustible) fire rating, these panels provide crucial fire safety for various projects. This rating ensures compliance with stringent safety standards, offering peace of mind to builders and occupants alike.

The fire-resistant nature of polyurethane separator boards is especially important in high-risk situations or in structures where fire security is a basic concern. By joining fire resistance with predominant cover properties, these boards offer a comprehensive arrangement for cutting edge development needs.

Indoor Air Quality and Health Considerations

The impact of building materials on indoor air quality is an increasingly important consideration in construction. Polyurethane insulation panels contribute positively to indoor environmental quality by creating an effective barrier against external pollutants and allergens. Their moisture-resistant properties also help prevent the growth of mold and mildew, which can adversely affect air quality and occupant health.

Moreover, the stability of polyurethane foam means that it does not off-gas harmful substances over time, maintaining a healthy indoor environment throughout the lifespan of the building. This characteristic is particularly valuable in residential settings and in facilities like schools or healthcare centers, where air quality is of utmost importance.

Conclusion

Polyurethane insulation panels represent a significant advancement in building insulation technology. Their superior thermal performance, versatility, and contribution to energy efficiency make them an invaluable asset in modern construction. As the industry continues to evolve towards more sustainable and high-performance building solutions, polyurethane insulation panels are poised to play an increasingly important role.

For those seeking to optimize their building's energy performance, comfort, and environmental impact, polyurethane insulation panels offer a compelling solution. To learn more about how these innovative panels can benefit your construction project, or to explore our range of exterior cladding and facade solutions, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.