Essential Treatments for Long-lasting Exterior Cladding

Protective Coatings: The First Line of Defense

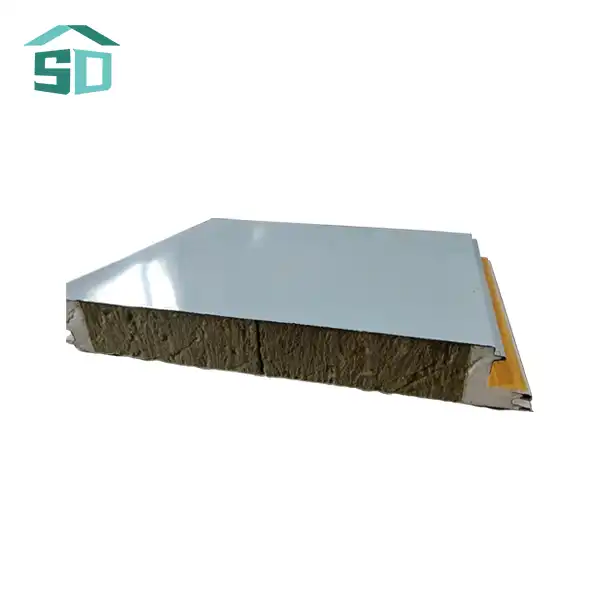

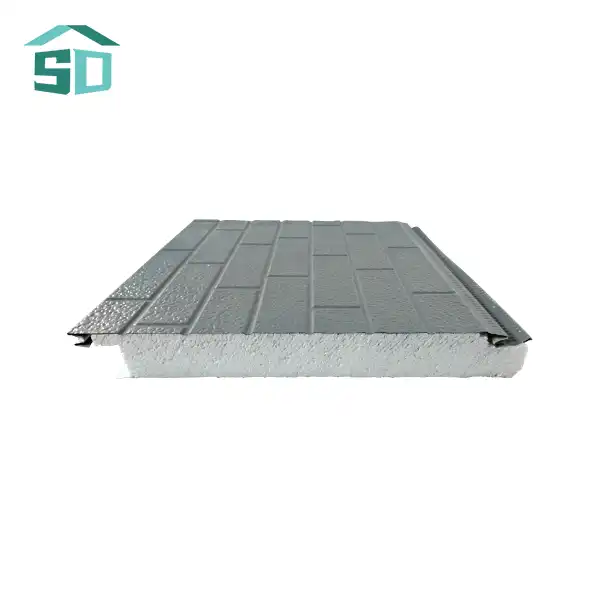

Protective coatings play a pivotal role in preserving the integrity and appearance of exterior cladding panels. These coatings act as a barrier against harsh environmental factors, including UV radiation, moisture, and pollutants. High-quality exterior cladding panels often come pre-treated with advanced coatings, but additional treatments can further enhance their durability.

For metal cladding panels, such as those made from aluminum, steel, stainless steel, or copper, anodizing is a popular treatment option. This electrochemical process creates a protective oxide layer on the metal surface, increasing its resistance to corrosion and wear. Anodized finishes are available in various colors, allowing for customization while maintaining the material's inherent properties.

Another effective treatment is powder coating. This dry finishing process involves applying electrostatically charged powder to the cladding surface, which is then cured under heat. Powder coating offers excellent durability, color retention, and resistance to chipping, scratching, and fading. It's particularly suitable for aluminum and steel cladding panels, providing a uniform, attractive finish that can withstand diverse weather conditions.

Sealants and Waterproofing: Guarding Against Moisture Intrusion

Moisture is one of the most significant threats to exterior cladding panels. Proper sealing and waterproofing are essential treatments to prevent water infiltration, which can lead to structural damage, mold growth, and reduced insulation efficiency. High-performance sealants should be applied to all joints, seams, and penetrations in the cladding system.

Silicone-based sealants are often preferred for their excellent flexibility, UV resistance, and long-lasting performance. These sealants can accommodate the natural expansion and contraction of cladding materials due to temperature fluctuations, ensuring a watertight seal throughout the year.

For additional protection, especially in areas prone to heavy rainfall or high humidity, a waterproof membrane can be applied behind the cladding panels. This extra layer acts as a secondary defense against moisture intrusion, enhancing the overall weather resistance of the building envelope.

Regular Maintenance: Preserving Performance and Aesthetics

While high-quality exterior cladding panelsare designed for low maintenance, regular care is still crucial for optimal performance and longevity. A comprehensive maintenance routine should include periodic inspections, cleaning, and touch-ups as needed.

Cleaning medications ought to be custom fitted to the particular fabric of the cladding boards. For occurrence, aluminum boards may require a mellow cleanser arrangement and delicate brushes to evacuate soil and grime without scratching the surface. Steel boards might advantage from specialized cleaners that expel rust spots and reestablish the defensive coating.

Annual inspections can help identify any areas that need attention, such as loose panels, deteriorating sealants, or signs of wear. Prompt addressing of these issues can prevent minor problems from escalating into major repairs, ensuring the cladding system continues to perform at its best.

Innovative Technologies in Exterior Cladding Treatments

Self-Cleaning Coatings: The Future of Low-Maintenance Cladding

Advancements in nanotechnology have led to the development of self-cleaning coatings for exterior cladding panels. These innovative treatments utilize photocatalytic properties to break down organic dirt and pollutants when exposed to sunlight. The result is a cladding surface that stays cleaner for longer, reducing maintenance requirements and preserving the building's aesthetic appeal.

A few self-cleaning coatings too join hydrophobic properties, causing water to globule up and roll off the surface, taking earth and flotsam and jetsam with it. This not as it were keeps the cladding cleaner but moreover upgrades its water-repellent qualities, giving extra security against moisture-related issues.

Anti-Graffiti Treatments: Protecting Urban Aesthetics

For buildings in urban environments, anti-graffiti treatments have become increasingly popular. These specialized coatings create a protective barrier on the cladding surface, making it difficult for graffiti to adhere and easier to remove if it does occur. Anti-graffiti treatments are particularly valuable for maintaining the appearance of public buildings, commercial properties, and residential complexes in high-traffic areas.

These treatments typically come in two forms: sacrificial coatings that are removed along with the graffiti and replaced after cleaning, and permanent coatings that allow for repeated graffiti removal without damaging the underlying surface. The choice between these options depends on factors such as the building's location, frequency of graffiti incidents, and maintenance budget.

Thermal Insulation Coatings: Enhancing Energy Efficiency

Exterior cladding panels play a crucial role in a building's thermal performance. Advanced thermal insulation coatings can further enhance this aspect, contributing to improved energy efficiency and reduced heating and cooling costs. These coatings work by reflecting solar radiation and reducing heat transfer through the building envelope.

Ceramic-based warm coatings are picking up notoriety for their capacity to give fabulous cover with a lean application. These coatings can be connected to different cladding materials, counting metal and composite boards, advertising a cost-effective way to boost a building's vitality execution without changing its appearance or basic keenness.

Choosing the Right Treatment for Your Exterior Cladding

Assessing Environmental Factors and Building Requirements

Selecting the appropriate treatment for exterior cladding panels requires careful consideration of various factors. The local climate plays a significant role in determining the most effective treatments. For instance, buildings in coastal areas may require additional corrosion-resistant treatments due to salt exposure, while structures in areas with high UV radiation might benefit from advanced UV-protective coatings.

The building's function and aesthetic requirements also influence treatment choices. Commercial buildings might prioritize treatments that offer easy maintenance and graffiti resistance, while residential properties may focus on treatments that enhance curb appeal and energy efficiency.

Material-Specific Treatments: Optimizing Performance

Diverse cladding materials require particular medications to optimize their execution. Aluminum cladding boards, known for their lightweight and corrosion-resistant properties, advantage from anodizing or powder coating to upgrade their strength and tasteful request. Steel boards, whereas intrinsically solid, may require extra rust-inhibiting medications to guarantee long-term execution, particularly in sticky situations.

Composite panels, which offer a balance of strength and design flexibility, often come with factory-applied finishes that provide excellent weather resistance. However, additional treatments can be applied to enhance their UV stability or provide specialized properties such as anti-microbial protection for healthcare facilities.

Balancing Cost and Long-Term Value

While initial treatment costs are an important consideration, it's crucial to evaluate the long-term value of different options. High-quality treatments may have a higher upfront cost but can significantly reduce maintenance requirements and extend the lifespan of the cladding system, resulting in lower total ownership costs over time.

For example, investing in advanced protective coatings and sealants can prevent moisture-related damage, potentially saving significant repair costs in the future. Similarly, choosing treatments that enhance energy efficiency can lead to substantial savings on heating and cooling expenses over the building's lifetime.

Conclusion

The best treatment for exterior cladding panels involves a holistic approach that considers the specific material properties, environmental conditions, and building requirements. By selecting appropriate protective coatings, implementing effective maintenance routines, and leveraging innovative technologies, building owners and managers can ensure their exterior cladding systems deliver optimal performance, durability, and aesthetic appeal for years to come.

For expert advice on selecting and maintaining exterior cladding panels tailored to your specific needs, contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of specialists can guide you through the latest advancements in cladding technologies and treatments, helping you make informed decisions for your building projects.