When it comes to metal siding panels for sheds, several types have gained popularity among homeowners and contractors alike. The most sought-after options include corrugated metal panels, standing seam panels, and metal lap siding. Corrugated panels offer a classic, industrial look and are known for their durability and cost-effectiveness. Standing seam panels provide a sleek, modern appearance and excellent weather resistance. Metal lap siding mimics the look of traditional wood siding while offering the longevity of metal. Each type has its unique benefits, making them suitable for various shed designs and personal preferences.

Understanding the Benefits of Metal Siding for Sheds

Durability and Longevity of Metal Siding Panels

Metal siding panels for sheds are renowned for their exceptional durability and longevity. Unlike traditional materials such as wood, metal siding can withstand harsh weather conditions, including heavy rain, snow, and intense sunlight. The robust nature of these panels ensures that your shed remains protected for years to come, reducing the need for frequent repairs or replacements. Many metal siding panels for shed suppliers offer products with corrosion-resistant coatings, further enhancing their ability to withstand the elements and maintain their appearance over time.

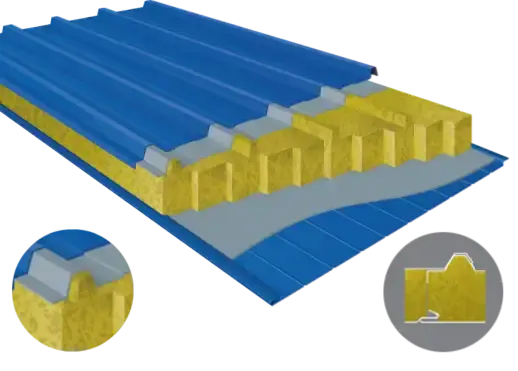

Energy Efficiency and Insulation Properties

One of the lesser-known benefits of metal siding panels for sheds is their contribution to energy efficiency. Many modern metal siding options come with built-in insulation or can be easily paired with additional insulating materials. This feature helps create a thermal barrier, keeping your shed cooler in summer and warmer in winter. The reflective properties of metal siding also play a role in temperature regulation, potentially reducing energy costs if your shed is climate-controlled. When selecting metal siding panels for your shed, consider options that offer superior insulation properties to maximize energy efficiency.

Aesthetic Versatility and Customization Options

Gone are the days when metal siding was limited to a plain, industrial look. Today's metal siding panels for sheds come in a wide array of colors, textures, and styles to suit any aesthetic preference. From sleek modern designs to panels that mimic the appearance of wood or stone, the options are virtually endless. Many metal siding panels for shed suppliers offer customization services, allowing you to choose specific colors or even create custom patterns. This versatility ensures that your shed can complement your home's exterior or stand out as a unique feature in your landscape.

Popular Types of Metal Siding Panels for Sheds

Corrugated Metal Panels: Classic and Cost-Effective

Corrugated metal panels remain a popular choice for shed siding due to their classic appearance and affordability. These panels feature a wavy or ridged pattern that not only adds visual interest but also enhances the material's strength. Corrugated metal siding panels for sheds are typically made from galvanized steel or aluminum, offering excellent resistance to rust and corrosion. Their lightweight nature makes installation relatively straightforward, potentially reducing labor costs. While traditionally associated with an industrial aesthetic, modern corrugated panels are available in various colors and finishes, allowing for greater design flexibility.

Standing Seam Panels: Modern and Weather-Resistant

For those seeking a more contemporary look, standing seam metal panels have become increasingly popular for shed siding. These panels are characterized by raised seams that run vertically from the roof to the base of the wall, creating clean, bold lines. The design of standing seam panels not only contributes to their modern appearance but also enhances their weather resistance by minimizing the number of exposed fasteners. Many metal siding panels for shed suppliers offer standing seam options in a range of colors and materials, including steel and aluminum. The superior water-shedding capabilities of these panels make them an excellent choice for areas with high rainfall or snow.

Metal Lap Siding: Traditional Look with Modern Benefits

Metal lap siding offers the best of both worlds - the traditional appearance of wood siding combined with the durability of metal. This type of metal siding panel for sheds is designed to mimic the overlapping pattern of traditional lap siding, creating a familiar and appealing aesthetic. However, unlike wood, metal lap siding resists rot, insect damage, and warping. It's available in a variety of textures and finishes, including options that closely resemble wood grain. For homeowners looking to maintain a cohesive look between their main house and shed, metal lap siding provides an excellent solution that doesn't compromise on durability or longevity.

Considerations When Choosing Metal Siding for Your Shed

Climate and Environmental Factors

When selecting metal siding panels for your shed, it's crucial to consider the specific climate and environmental conditions of your area. Different types of metal siding may perform better in certain environments. For instance, in coastal areas with high salt content in the air, aluminum siding might be preferable due to its superior corrosion resistance. In regions with extreme temperature fluctuations, consider metal siding panels for sheds that offer good insulation properties or can accommodate additional insulation. Some metal siding panels for shed suppliers offer specialized coatings designed to withstand specific environmental challenges, such as UV-resistant finishes for areas with intense sunlight.

Maintenance Requirements and Long-Term Costs

While metal siding is generally low-maintenance compared to other materials, different types of metal siding panels for sheds may have varying maintenance needs. Consider factors such as how often the siding will need to be cleaned, whether it requires periodic repainting or resealing, and how easy it is to replace individual panels if damage occurs. Although metal siding may have a higher upfront cost compared to some alternatives, its longevity and minimal maintenance requirements often result in lower long-term costs. When evaluating options from metal siding panels for shed suppliers, inquire about warranties and expected lifespan to get a clear picture of the long-term value.

Installation Complexity and Professional Requirements

The installation process for metal siding panels can vary significantly depending on the type you choose. Some options, like corrugated panels, may be suitable for DIY installation if you have the right tools and experience. However, more complex systems like standing seam panels often require professional installation to ensure proper sealing and optimal performance. When considering different metal siding panels for sheds, factor in the installation costs and requirements. Some metal siding panels for shed suppliers may offer installation services or can recommend certified installers familiar with their products. Professional installation can help ensure that your metal siding performs as intended and may be necessary to maintain warranty coverage.

Conclusion

Metal siding panels for sheds offer a compelling combination of durability, aesthetics, and functionality. From the classic appeal of corrugated panels to the modern sophistication of standing seam options and the traditional look of metal lap siding, there's a metal siding solution to suit every shed design and homeowner preference. By carefully considering factors such as climate, maintenance requirements, and installation complexity, you can select the ideal metal siding for your shed project. The long-term benefits of metal siding, including its longevity, energy efficiency, and low maintenance needs, make it an excellent investment for protecting and enhancing your outdoor storage space.

Are you ready to elevate your shed with high-quality metal siding panels? At Weifang Sandong Building Materials Co., Ltd., we offer a wide range of exterior cladding solutions, including top-of-the-line metal siding panels for sheds. Our products combine durability, aesthetics, and energy efficiency to meet all your shed siding needs. Contact us today at info@sdqsc.com to explore our selection and find the perfect metal siding for your project.

FAQ

How long does metal siding typically last on a shed?

With proper installation and maintenance, metal siding can last 40-70 years, depending on the specific material and environmental conditions.

Can metal siding be painted if I want to change the color of my shed?

Yes, most metal siding can be painted. However, it's important to use paint specifically designed for metal surfaces and properly prepare the siding before painting.

Is metal siding noisy during rain or hail?

While older metal siding could be noisy, modern metal siding panels for sheds often incorporate sound-dampening technologies or can be installed with insulation to minimize noise.

References

1. Metal Construction Association. (2021). "Metal Roofing and Wall Systems Performance Guide."

2. U.S. Department of Energy. (2020). "Guide to Home Insulation."

3. National Association of Home Builders. (2019). "Life Expectancy of Home Components."

4. American Iron and Steel Institute. (2022). "Steel Market Development Institute Report on Residential Construction."

(1).jpg改.webp)