The Engineering Marvel Behind Collapsible Container Houses

Innovative Folding Mechanisms

At the heart of collapsible container houses lies an ingenious folding mechanism that transforms a compact package into a fully functional living space. This system typically consists of hinged walls and floors that can be easily unfolded and locked into place. The engineering behind these mechanisms ensures that the structure remains sturdy and secure once assembled, while still allowing for quick disassembly when needed.

Weifang Sandong Building Materials Co., Ltd., a global provider of exterior cladding and facade solutions, has incorporated advanced folding technologies into their container house designs. Their model, with dimensions of L5800mm*W2400mm*H2500mm, exemplifies the precision engineering required for seamless assembly and disassembly.

Pre-fabricated Components

The ease of assembly is further enhanced by the use of pre-fabricated components. These elements are manufactured off-site under controlled conditions, ensuring high quality and consistency. When delivered to the construction site, these pre-made parts fit together like pieces of a puzzle, significantly reducing on-site labor and construction time.

Pre-fabrication extends to various aspects of the container house, including:

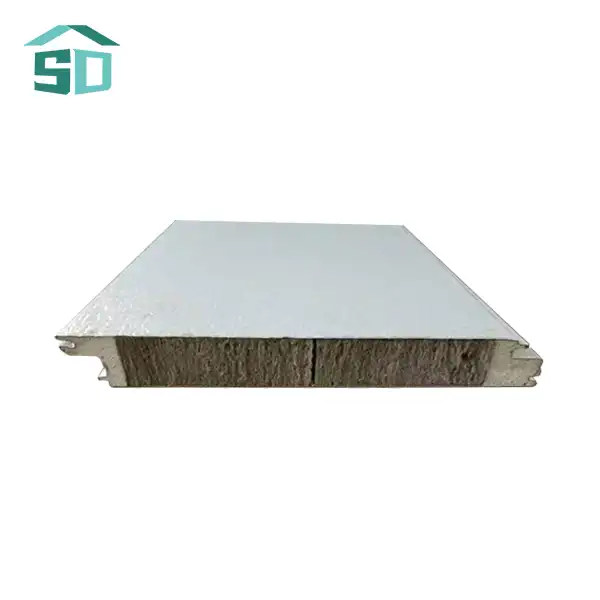

- Wall panels with pre-installed insulation (Fiberglass, Rock wool, or PU)

- Flooring systems

- Roof modules with customizable options

- Pre-wired electrical systems

- Plumbing fixtures and connections

This level of pre-fabrication not only speeds up assembly but also minimizes the potential for errors during construction.

Standardized Connections and Modular Design

Standardization is a key factor in the simplicity of collapsible container house assembly. By utilizing standardized connections and a modular design approach, these structures can be put together with minimal specialized tools or expertise. This standardization extends to the container's base structure, which often adheres to ISO standards, ensuring compatibility with existing transportation and handling equipment.

The modular nature of these houses allows for easy expansion or reconfiguration. Additional modules can be connected to create larger spaces, or the layout can be modified to suit changing needs. This flexibility is particularly valuable for applications such as camps, schools, dormitories, and mining accommodations, as mentioned in the product specifications.

Materials and Construction Techniques

High-Quality, Durable Materials

The materials used in collapsible container houses play a crucial role in their ease of assembly and long-term performance. The primary structure is typically made from high-strength steel, similar to that used in shipping containers. This provides a robust framework that can withstand the rigors of transportation and repeated assembly/disassembly cycles.

Shandong Building Materials, the brand behind these innovative structures, ensures that all materials meet or exceed industry standards. The use of quality materials contributes to the impressive 70-year lifespan mentioned in the product specifications, making these houses a durable and sustainable housing solution.

Advanced Insulation Systems

Insulation is a critical component of collapsible container houses, especially when used in diverse climates. The product specifications mention three insulation options:

- Fiberglass

- Rock wool

- PU (Polyurethane)

These insulation materials are typically pre-installed in the wall panels, floor, and roof sections. The integration of insulation during the manufacturing process ensures consistent quality and eliminates the need for time-consuming on-site insulation installation. This pre-insulated design contributes significantly to the energy-saving features of the container house and simplifies the assembly process.

Lightweight Yet Robust Construction

Despite their durability, collapsible container houses are designed to be relatively lightweight. This characteristic is crucial for easy transportation and assembly. The use of light gauge steel framing, as mentioned in Weifang Sandong Building Materials Co., Ltd.'s product range, is an example of how modern materials can provide strength without excessive weight.

The lightweight nature of these structures does not compromise their robustness. They are engineered to meet various international standards, including ISO, CE, AS, US, and CA certifications. This ensures that the houses can withstand diverse environmental conditions and meet global safety requirements.

Technological Advancements in Assembly

3D Modeling and Precision Manufacturing

The ease of assembly in collapsible container houses is greatly enhanced by the use of advanced 3D modeling techniques. As mentioned in the product specifications, the design process includes "Plan & 3D Model & Structural Design." This approach allows for precise planning and visualization of the entire structure before manufacturing begins.

3D modeling facilitates:

- Accurate dimensioning of all components

- Identification and resolution of potential assembly issues before production

- Creation of detailed assembly instructions for on-site teams

- Optimization of the folding mechanism for efficient packing and deployment

The use of 3D modeling, combined with precision manufacturing techniques, ensures that all components fit together perfectly during assembly, minimizing the need for on-site adjustments or modifications.

Smart Connection Systems

Innovative connection systems have significantly contributed to the ease of assembling collapsible container houses. These systems often include:

- Quick-lock mechanisms for joining wall panels

- Self-aligning connectors for roof and floor sections

- Plug-and-play electrical and plumbing connections

These smart connection systems reduce the need for specialized tools and skilled labor during assembly. They also allow for rapid disassembly when the structure needs to be relocated or reconfigured.

Integration of Smart Home Technologies

While not explicitly mentioned in the product specifications, many modern collapsible container houses are designed with the integration of smart home technologies in mind. This forward-thinking approach includes:

- Pre-wired systems for easy installation of smart lighting and climate control

- Integrated sensors for monitoring structural integrity and environmental conditions

- Compatibility with modular smart home systems for easy customization

These technological integrations not only enhance the living experience but also contribute to the energy-saving features mentioned in the product specifications. They can provide real-time data on the house's performance and help optimize energy usage.

Conclusion

Collapsible container houses represent a significant advancement in modular construction, offering a perfect blend of durability, flexibility, and ease of assembly. Their innovative design, incorporating folding mechanisms, prefabricated components, and standardized connections, allows for rapid deployment in various settings. The use of high-quality materials and advanced manufacturing techniques ensures that these structures meet international standards while providing energy-efficient and long-lasting housing solutions.

As the demand for flexible and sustainable housing continues to grow, collapsible container houses are poised to play an increasingly important role in addressing global housing challenges. Their ability to be quickly assembled, disassembled, and transported makes them ideal for a wide range of applications, from temporary housing in disaster-stricken areas to permanent residences in remote locations.

For more information about exterior cladding, facade solutions, and innovative building materials, including collapsible container houses, please contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your construction needs.