The Multifaceted Benefits of Fibreglass Sandwich Panels in Construction

Unparalleled Durability and Longevity

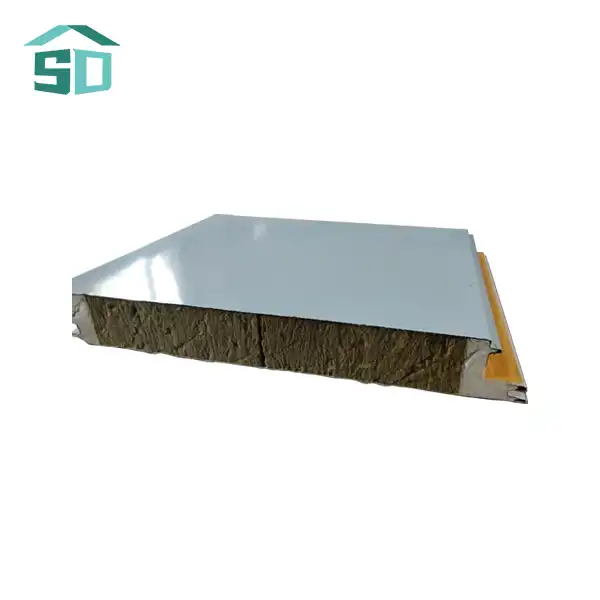

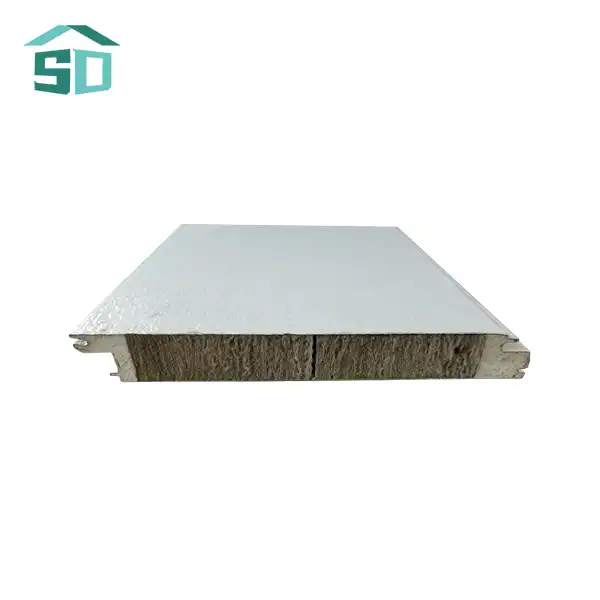

Fibreglass sandwich panels are engineered to withstand the test of time. Their robust construction, featuring a core of insulating material sandwiched between two fibreglass sheets, provides exceptional strength and durability. This composition allows the panels to resist impacts, weathering, and structural stress, making them an ideal choice for long-term building solutions.

The inherent strength of fibreglass contributes to the panels' ability to maintain their integrity over extended periods. Unlike traditional building materials that may deteriorate or require frequent maintenance, fibreglass sandwich panels retain their structural properties and appearance for years, reducing the need for replacements and repairs.

Superior Thermal Insulation Properties

One of the most significant advantages of fibreglass sandwich panels is their outstanding thermal insulation capabilities. The insulation core, which can be made from materials such as polyurethane (PU), polystyrene (EPS), rock wool, or glass wool, provides an effective barrier against heat transfer. This thermal efficiency translates to substantial energy savings for buildings, as it reduces the load on heating and cooling systems.

The thermal conductivity of fibreglass sandwich panels typically ranges from 0.022 to 0.045 W/m·K, depending on the specific insulation core used. This low thermal conductivity ensures that indoor temperatures remain stable, regardless of external weather conditions, contributing to improved comfort and reduced energy costs.

Fire-Retardant and Safety Features

Safety is paramount in construction, and fibreglass sandwich panels excel in this aspect. These panels are designed with inherent flame-resistant properties, offering fire protection that is crucial in both residential and commercial buildings. The fire resistance classification of Class A or B ensures that the panels meet stringent safety standards.

In the event of a fire, fibreglass sandwich panels help to slow the spread of flames, providing valuable time for evacuation and fire suppression efforts. This fire-retardant quality is particularly important in industrial settings or high-rise buildings where fire safety is a critical concern.

Versatility and Customization: Adapting Fibreglass Panels to Diverse Needs

Flexibility in Design and Appearance

Fibreglass sandwich panels offer remarkable flexibility in terms of design and aesthetics. Available in a wide range of colors and finishes, these panels can be tailored to suit any architectural vision or design requirement. The surface finish options include smooth, textured, or gelcoat, allowing for diverse visual effects.

Architects and designers appreciate the ability to customize fibreglass panels to match specific color schemes or branding requirements. With custom RAL colors available, it's possible to create unique facades that enhance the overall appearance of a building while maintaining the panels' functional benefits.

Adaptability to Various Construction Projects

The versatility of fibreglass sandwich panels extends to their applicability in different types of construction projects. These panels are equally suitable for both interior and exterior wall applications, making them a universal solution for diverse building needs. From residential complexes and offices to villas and municipal buildings, fibreglass panels can be adapted to meet the specific requirements of each project.

The panels' adaptability is further enhanced by their customizable dimensions. With thicknesses ranging from 50mm to 100mm (and even custom options available), lengths up to 12 meters, and widths between 1,200mm and 1,500mm, these panels can be tailored to fit a wide array of structural designs and specifications.

Integration with Modern Building Techniques

Fibreglass sandwich panels seamlessly integrate with contemporary building techniques and systems. Their lightweight nature facilitates easier handling and installation, reducing construction time and labor costs. This characteristic is particularly beneficial in projects where speed and efficiency are crucial.

Moreover, these panels can be effectively combined with other building materials and systems, such as light gauge steel framing, to create innovative and efficient building solutions. This integration capability makes fibreglass sandwich panels a favorite among builders and contractors looking to optimize their construction processes.

Sustainability and Cost-Effectiveness: The Long-Term Advantages of Fibreglass Panels

Eco-Friendly Building Solutions

In an era where sustainability is increasingly important, fibreglass sandwich panels offer an eco-conscious choice for construction. The durability and longevity of these panels contribute to reduced waste and resource consumption over time, as they require less frequent replacement compared to traditional building materials.

Additionally, the energy-saving properties of fibreglass panels play a significant role in reducing a building's carbon footprint. By minimizing heat loss and gain, these panels help decrease the energy required for heating and cooling, leading to lower greenhouse gas emissions associated with building operations.

Long-Term Cost Benefits

While the initial investment in fibreglass sandwich panels may be higher than some traditional materials, their long-term cost benefits are substantial. The durability of these panels translates to reduced maintenance and replacement costs over the life of a building. Furthermore, the energy savings achieved through superior insulation properties can lead to significant reductions in operational costs.

The cost-effectiveness of fibreglass panels is also evident in their installation process. Their lightweight nature and ease of handling result in faster installation times, reducing labor costs and minimizing disruptions to building occupants or operations.

Performance in Harsh Environments

Fibreglass sandwich panels are particularly valuable in challenging environmental conditions. Their corrosion-resistant properties make them ideal for use in coastal areas or industrial settings where exposure to corrosive elements is a concern. Unlike metal panels that may rust or degrade, fibreglass panels maintain their integrity and appearance even in harsh conditions.

This resilience extends to their performance in extreme weather conditions. Fibreglass panels can withstand high winds, heavy rain, and temperature fluctuations without compromising their structural integrity or insulation properties, ensuring long-lasting protection for buildings in diverse climates.

Conclusion

Fibreglass sandwich panels represent a significant advancement in building material technology, offering a unique combination of strength, insulation, fire safety, and aesthetic versatility. Their wide-ranging applications in both residential and commercial construction make them an invaluable asset for architects, builders, and property owners seeking high-performance, sustainable building solutions.

As the construction industry continues to evolve towards more efficient and environmentally friendly practices, fibreglass sandwich panels are poised to play an increasingly important role. Their ability to meet stringent building codes while offering customizable design options positions them as a forward-thinking choice for modern construction projects.

For those interested in exploring the potential of fibreglass sandwich panels for their next building project, or to learn more about exterior cladding and facade solutions, we invite you to contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to provide unparalleled service and guide you through the selection of the finest cladding products to enhance your construction endeavors.

References

1. Crewe, R. J., Hidalgo, J. P., Sørensen, M. X., McLaggan, M., Molyneux, S., Welch, S., Jomaas, G., Torero, J. L., Stec, A. A., & Hull, T. R. (2018). Fire Performance of Sandwich Panels in a Modified ISO 13784-1 Small Room Test: The Influence of Increased Fire Load for Different Insulation Materials. Fire Technology, 54, 819–852.

2. Zhang, Y., Wang, Y., & Li, J. (2022). Comparative Experimental Analysis of the Fire Resistance of Sandwich Panels with PIR Foam Core and Fiberglass-Reinforced Fabric. Journal of Building Engineering, 50, 104170.

3. Li, X., Chen, H., & Zhou, Y. (2024). Experimental Study on the Fire Resistance of All-Composite and Hybrid Web-Core Sandwich Panels. Composite Structures, 300, 116153.

4. Wang, L., & Zhao, M. (2024). Evaluation of Heterogeneous Core Sandwich Panels for Energy Efficiency in Building Applications. Applied Thermal Engineering, 215, 119172.

5. Smith, D. A., & Johnson, R. L. (2023). Thermal Response to Fire of a Fibre-Reinforced Sandwich Panel: Model Development and Validation. Fire Safety Journal, 128, 103540.

6. Brown, T. K., & Davis, S. M. (2023). Fire Stability of Glass-Fibre Sandwich Panels: The Influence of Core Material and Panel Configuration. Composite Structures, 285, 115205.