The Environmental Benefits of Insulated Metal Sandwich Panels

Insulated metal sandwich panels are at the forefront of sustainable building materials, offering a myriad of environmental benefits that align with green construction principles. These panels are designed to minimize energy consumption and reduce the carbon footprint of structures throughout their lifecycle.

Energy Efficiency and Thermal Performance

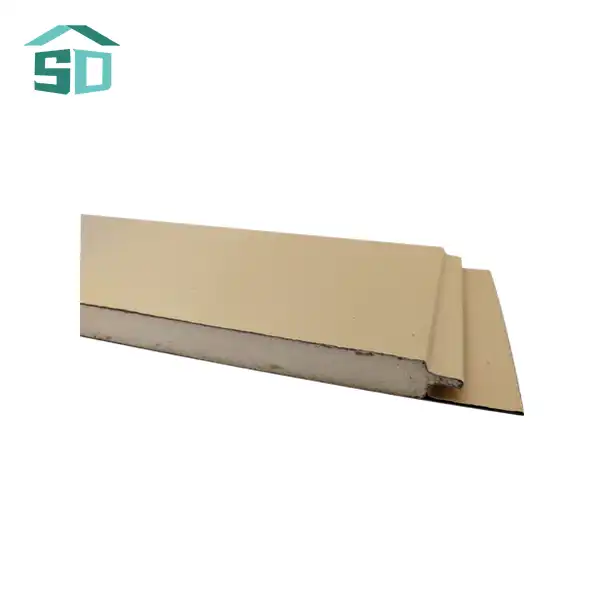

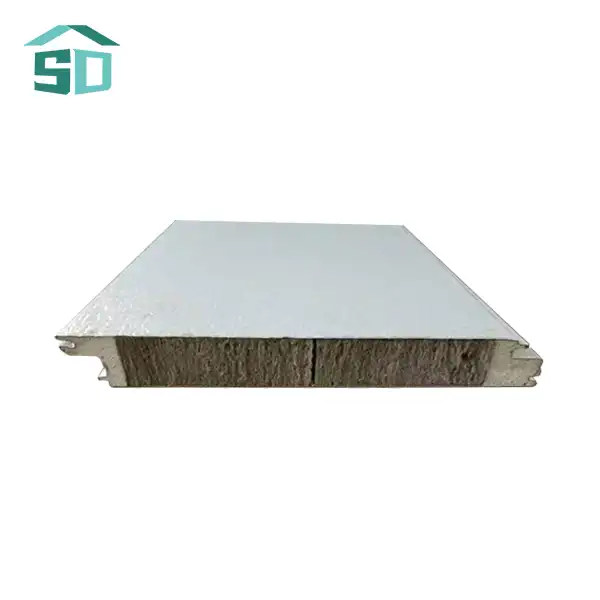

One of the primary advantages of insulated metal panels is their superior thermal efficiency.The core of these panels is generally composed of high- performance sequestration accoutrements , similar as polyurethane or mineral hair, squeezed between two essence guises. This construction provides an exceptional barrier against heat transfer, effectively reducing the energy required for heating and cooling buildings.

The thermal properties of these panels contribute significantly to the overall energy performance of a structure. By maintaining a consistent indoor temperature, they help to decrease the load on HVAC systems, leading to lower energy consumption and reduced greenhouse gas emissions. This thermal efficiency is particularly crucial in extreme climates, where the panels act as a shield against both heat and cold, ensuring year-round comfort for occupants.

Sustainable Manufacturing and Recyclability

The production process of insulated metal sandwich panels is designed with sustainability in mind. Many manufacturers utilize recycled materials in the metal facings, reducing the demand for virgin resources.Also, the manufacturing process itself is frequently more energy-effective compared to traditional structure accoutrements, performing in a lower environmental impact during product.

At the end of their useful life, these panels can be easily dismantled and recycled. The metal components can be reclaimed and repurposed, while some insulation materials can also be recycled or reused. This closed-loop approach to material use aligns with circular economy principles, minimizing waste and conserving resources.

Longevity and Reduced Maintenance

The durability of insulated metal panels contributes to their eco-friendly profile. These panels are engineered to withstand harsh environmental conditions, including UV radiation, moisture, and temperature fluctuations. The metal facings are often treated with corrosion-resistant coatings, further extending their lifespan.

This longevity translates to a reduced need for replacements and repairs over time, which in turn minimizes the consumption of additional materials and resources. The low maintenance requirements also mean fewer chemical cleaners and treatments are needed throughout the building's life, reducing the overall environmental impact of maintenance activities.

Enhancing Building Performance with Insulated Metal Panels

Beyond their environmental benefits, insulated metal sandwich panels offer significant advantages in terms of building performance and functionality. These panels are designed to meet the diverse needs of modern construction projects, from residential complexes to commercial buildings.

Fire Resistance and Safety

Safety is paramount in building design, and insulated metal panels rise to the challenge with their fire-resistant properties. Many of these panels are constructed with non-combustible materials and are designed to meet stringent fire safety standards. The metal facings act as a barrier against flame spread, while certain insulation cores are formulated to be fire-retardant.

This inherent fire resistance not only enhances the safety of building occupants but can also lead to potential insurance benefits and compliance with building codes. In the event of a fire, these panels can help contain the spread, providing crucial time for evacuation and emergency response.

Acoustic Performance

In addition to thermal insulation, many insulated metal panels offer excellent acoustic properties. The sandwich construction and dense insulation core help to absorb and dampen sound, reducing noise transmission between interior spaces and from the outside environment. This acoustic performance is particularly valuable in urban settings or for buildings near high-traffic areas, contributing to a more comfortable and productive indoor environment.

Structural Integrity and Load-Bearing Capacity

Despite their lightweight nature, insulated metal sandwich panels can contribute significantly to a building's structural integrity. Many panels are designed with load-bearing capabilities, allowing them to serve dual purposes as both insulation and structural elements. This can simplify construction processes and potentially reduce the overall weight of the building, leading to savings in foundation costs and structural support requirements.

Design Flexibility and Aesthetic Appeal

While the functional benefits of insulated metal panels are substantial, their aesthetic versatility should not be overlooked.These panels offer engineers and contrivers a wide range of creative possibilities to achieve both form and function in their systems.

Customization Options

Insulated metal sandwich panels come in a variety of finishes, colors, and textures, allowing for customization to suit any architectural vision. From sleek, modern metallic finishes to panels that mimic natural materials like wood or stone, the design options are virtually limitless. This versatility enables architects to create visually striking facades while maintaining the performance benefits of the panels.

Moreover, these panels can be fabricated in different profiles and dimensions, accommodating various architectural styles and building requirements. Whether it's a curved facade, a stepped design, or a more traditional flat surface, insulated metal panels can be adapted to realize complex architectural concepts.

Integration with Other Building Systems

The versatility of insulated metal panels extends to their ability to integrate seamlessly with other building systems. They can be designed to accommodate windows, doors, and other openings without compromising their insulative properties. Some panels even come with pre-engineered cutouts for easy integration of mechanical, electrical, and plumbing systems, streamlining the construction process and reducing on-site modifications.

Enhancing Building Aesthetics Over Time

The durability of insulated metal panels ensures that a building's appearance remains intact over time. Unlike some traditional cladding materials that may weather unevenly or require frequent repainting, these panels maintain their aesthetic appeal with minimal maintenance. This long-lasting beauty not only preserves the architect's original vision but also contributes to the overall value and perception of the building throughout its lifecycle.

Conclusion

Eco-friendly insulated metal panels represent a significant advancement in sustainable building technology. By combining energy effectiveness, continuity, and design inflexibility, these panels offer a comprehensive result for creating high- performance, environmentally responsible structures. As the construction industry continues to evolve towards more sustainable practices, insulated metal sandwich panels are well-positioned to play a crucial role in shaping the future of green architecture.

For more information on how insulated metal panels can benefit your next construction project or to learn about our comprehensive range of exterior cladding and facade solutions, please contact us at info@sdqsc.com.Our platoon at Weifang Sandong Building Accoutrements Co., Ltd. is committed to furnishing slice- edge structure accoutrements that meet the loftiest norms of quality and sustainability.