The Structural Prowess of 10 cm Sandwich Panels

The 10 cm sandwich panel stands as a paragon of structural integrity in the world of construction materials. Its impressive strength stems from a combination of advanced engineering and high-quality components. Let's delve into the factors that contribute to its robustness:

Composition and Design

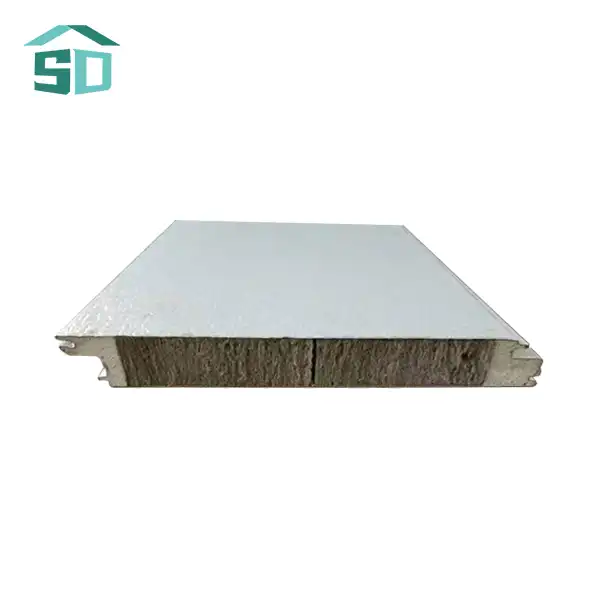

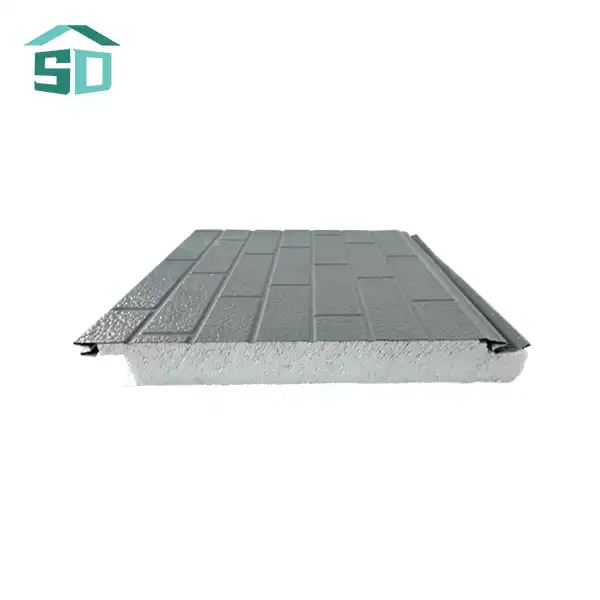

At the heart of the 10 cm sandwich panel's strength lies its tri-layer composition. Two outer metal sheets, typically made of steel, aluminum, or stainless steel, sandwich a core of insulation material. This core can be polyurethane (PU), polystyrene (EPS), or rock wool, each offering unique properties. The synergy between these layers creates a panel that is not only lightweight but also remarkably strong.

The metal faces provide tensile and compressive strength, while the core material distributes loads evenly across the panel. This design allows the 10 cm sandwich panel to resist bending and twisting forces far better than traditional single-layer materials. The thickness of 10 cm is particularly optimal, offering a balance between weight and strength that makes it suitable for a wide range of applications.

Manufacturing Process

The strength of the 10 cm sandwich panel is further enhanced by its manufacturing process. Advanced production lines employ precise bonding techniques to ensure a strong, uniform connection between the core and the metal faces. This bonding is crucial, as it allows the panel to act as a single unit under stress, rather than as separate components.

Quality control measures play a vital role in maintaining the panel's strength. Rigorous testing of raw materials, including steel coils and insulation components, ensures that only the highest quality inputs are used. The finished panels undergo comprehensive inspections for thickness, mechanical strength, and overall integrity, guaranteeing that each 10 cm sandwich panel meets stringent performance standards.

Performance Metrics and Applications

The strength of a 10 cm sandwich panel is not just theoretical; it translates into impressive real-world performance. These panels exhibit remarkable load-bearing capacity, making them suitable for both vertical and horizontal applications in construction.

Load-Bearing Capacity

Depending on the specific materials used, a 10 cm sandwich panel can support substantial loads. For instance, panels with steel faces and a polyurethane core can often withstand distributed loads of several hundred kilograms per square meter. This strength allows them to be used in roofing applications, where they must support not only their own weight but also additional loads from snow, wind, and maintenance traffic.

In vertical applications, such as wall cladding, the 10 cm sandwich panel's strength manifests as excellent resistance to wind loads. This is particularly important in high-rise buildings or structures in areas prone to strong winds or storms.

Versatility in Construction

The robust nature of 10 cm sandwich panels makes them versatile components in various construction projects. They find application in:

- Industrial buildings and warehouses

- Commercial structures like offices and retail spaces

- Residential complexes and modern villas

- Cold storage facilities and clean rooms

- Agricultural buildings and storage units

In each of these settings, the 10 cm sandwich panel's strength contributes to the overall structural integrity of the building while also providing excellent insulation and aesthetic appeal.

Durability and Longevity

The strength of a 10 cm sandwich panel is not just about its immediate load-bearing capacity; it's also about long-term performance and durability. These panels are designed to maintain their structural integrity over extended periods, even in challenging environments.

Resistance to Environmental Factors

One of the key aspects of the 10 cm sandwich panel's durability is its resistance to environmental degradation. The metal faces are typically treated with protective coatings or paints that guard against corrosion, UV radiation, and moisture. This protection ensures that the panel's strength is not compromised over time due to exposure to the elements.

The core material also plays a role in the panel's longevity. Materials like polyurethane and rock wool are resistant to moisture absorption, preventing internal degradation that could weaken the panel's structure. This moisture resistance is particularly important in humid climates or applications where condensation might be an issue.

Fire Resistance and Safety

Another crucial aspect of the 10 cm sandwich panel's strength is its fire resistance. Depending on the core material used, these panels can achieve fire ratings from Class A to B. This fire resistance is not just about safety; it's also about maintaining structural integrity in the event of a fire, potentially preventing catastrophic building collapse.

The non-combustible nature of materials like rock wool core panels adds an extra layer of safety and durability to structures. This feature is particularly valued in industrial settings or public buildings where fire safety is paramount.

Conclusion

the 10 cm sandwich panel represents a pinnacle of strength and durability in modern construction materials. Its robust design, versatile applications, and long-term performance make it an excellent choice for a wide range of building projects. As the construction industry continues to evolve, these panels stand as a testament to the power of innovative engineering in creating materials that are not just strong, but also efficient, safe, and sustainable. For more information on how 10 cm sandwich panels can enhance your construction projects, feel free to contact us at info@sdqsc.com.