The Anatomy of a 10 cm Sandwich Panel: Unveiling Its Layers

To truly appreciate the engineering marvel that is a 10 cm sandwich panel, we must delve into its intricate anatomy. These panels are meticulously crafted to provide optimal performance in various construction scenarios. Let's explore the key components that make up these versatile building materials.

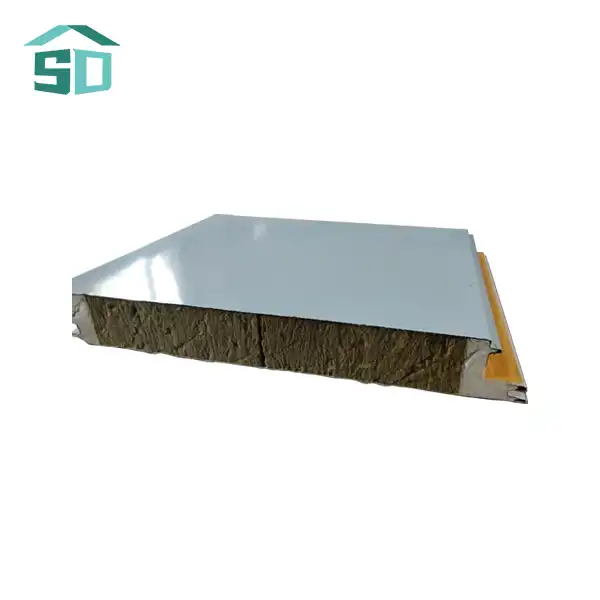

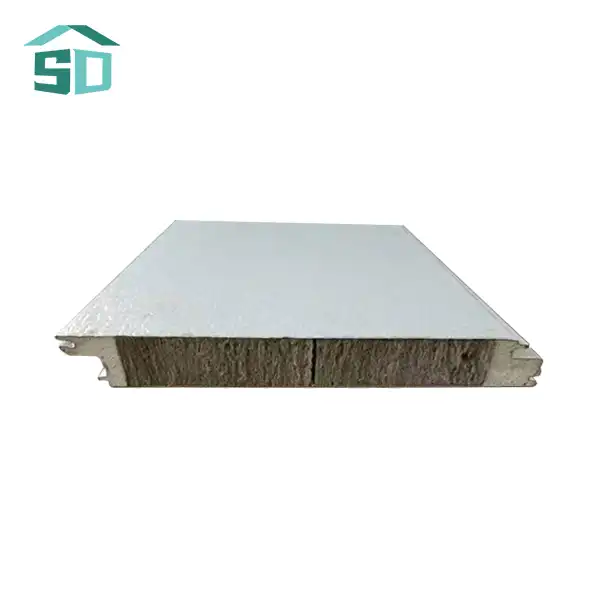

Outer Facing Sheets: The Protective Shield

The outer-facing sheets of a 10 cm sandwich panel serve as its first line of defense against external elements. Typically fabricated from robust materials such as steel, aluminum, or stainless steel, these sheets provide exceptional durability and resistance to weathering. These sheets come in various thicknesses, tailored to handle the demands of both indoor and outdoor use.

A key advantage of these facing panels is their adaptability in appearance and surface finish. They can be treated with coatings, paint, or anodizing for enhanced durability and visual appeal. With nearly endless color choices—thanks to RAL customization—designers have the freedom to craft eye-catching facades that suit a wide range of architectural styles.

Insulation Core: The Heart of Thermal Efficiency

At the core of a 10 cm sandwich panel lies its insulation material, which plays a crucial role in its thermal performance. The most common insulation materials used are polyurethane (PU), expanded polystyrene (EPS), and rock wool. Each of these materials offers unique properties that contribute to the panel's overall performance.

Polyurethane (PU) is renowned for its excellent insulation properties and low thermal conductivity. It provides superior energy efficiency, making it an ideal choice for buildings that require optimal temperature control. Expanded polystyrene (EPS) offers a balance of insulation and cost-effectiveness, while rock wool excels in fire resistance and sound insulation.

The 10 cm thickness of these panels allows for a substantial insulation core, significantly enhancing their thermal performance. This increased thickness translates to improved energy efficiency in buildings, potentially leading to reduced heating and cooling costs over time.

Adhesive Layer: The Invisible Bond

While often overlooked, the adhesive layer that bonds the facing sheets to the insulation core is a critical component of a 10 cm sandwich panel. This layer ensures the structural integrity of the panel, allowing it to function as a single, cohesive unit. The adhesive applied needs to be robust enough to endure thermal expansion, contraction, and physical stress on the panel. The bond’s quality plays a key role in the panel’s strength and service life. Well-made 10 cm sandwich panels use advanced adhesives that retain their performance even under changing environmental conditions.

Performance Characteristics of 10 cm Sandwich Panels

The substantial 10 cm thickness of these sandwich panels contributes significantly to their exceptional performance characteristics. These panels are finagled to exceed in colorful aspects, making them a favored choice for both engineers and builders in a wide range of construction systems.

Thermal Insulation: A Cut Above the Rest

One of the most notable benefits of a 10 cm sandwich panel is its superior thermal insulation properties. The increased thickness allows for a larger volume of insulating material, resulting in significantly improved thermal performance. This enhanced insulation capability translates to better energy efficiency in buildings, potentially leading to substantial savings on heating and cooling costs over time.

The thermal performance of these panels is particularly valuable in regions with extreme climates. Whether it's keeping the heat out in scorching summers or retaining warmth during frigid winters, 10 cm sandwich panels provide a reliable barrier against temperature fluctuations.

Structural Integrity and Durability

The 10 cm thickness of these sandwich panels doesn't just contribute to their insulation properties; it also significantly enhances their structural integrity. The increased thickness results in a more robust panel that can withstand greater loads and resist deformation under stress.

This improved structural performance makes 10 cm sandwich panels an excellent choice for large-scale construction projects where durability is paramount. From expansive warehouse walls to high-rise building facades, these panels provide the strength and longevity needed in demanding applications.

Fire Resistance and Safety

Safety is a critical consideration in any construction project, and 10 cm sandwich panels excel in this area as well. Depending on the insulation material used, these panels can achieve fire ratings ranging from Class A to B. This fire resistance plays an important role in limiting flame spread during a fire, which can help protect lives and reduce property damage.

The non-combustible nature of many of the materials used in these panels, particularly when rock wool insulation is chosen, further enhances their safety profile. This makes 10 cm sandwich panels an excellent choice for buildings where fire safety is a top priority, such as schools, hospitals, and high-occupancy commercial structures.

Applications and Benefits of 10 cm Sandwich Panels

The adaptability and high functionality of 10 cm sandwich panels make them ideal for various uses across the construction sector.From residential buildings to industrial complexes, these panels offer numerous benefits that make them an attractive option for builders and architects alike.

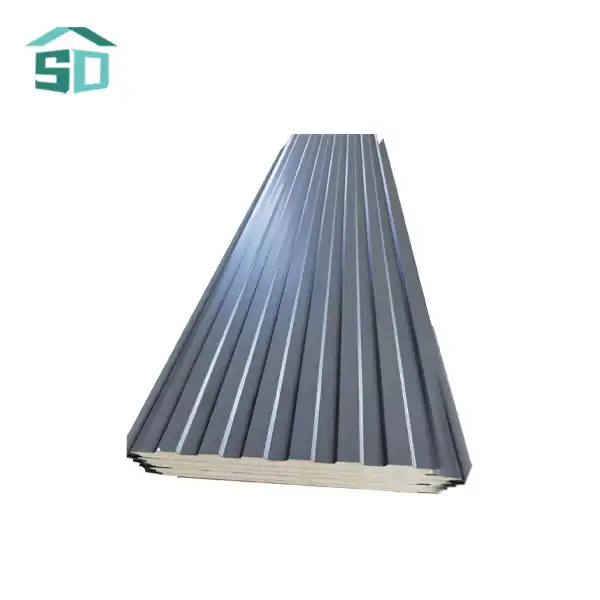

Versatile Application in Construction

The robust nature of 10 cm sandwich panels allows them to be used in both interior and exterior applications. In exterior settings, they serve as effective cladding solutions, providing an attractive finish while offering protection against the elements. Their substantial thickness makes them particularly well-suited for large-scale projects such as industrial warehouses, where thermal insulation and durability are crucial.

Internally, these panels can be used to create partition walls or suspended ceilings, offering excellent sound insulation properties in addition to their thermal benefits. This versatility makes 10 cm sandwich panels a valuable asset in creating comfortable, energy-efficient spaces across various building types.

Aesthetic Flexibility and Customization

One of the often-overlooked benefits of 10 cm sandwich panels is their aesthetic flexibility. These panels can be customized in a variety of colors and finishes, allowing architects to create visually striking facades that complement the overall design of a building. The ability to choose from a wide range of colors based on the RAL color chart ensures that these panels can meet even the most exacting design requirements.

Likewise, the face of these panels can be treated in colorful ways, including coating, oil, or anodizing, to achieve different visual goods and fresh protection. This position of customization allows for the creation of unique, eye- catching surfaces that can set a structure piecemeal from its surroundings.

Long-Term Cost Benefits

While the initial cost of 10 cm sandwich panels may be higher than some alternatives, their long-term benefits often result in significant cost savings over time. The superior insulation properties of these panels can lead to substantial reductions in energy costs for heating and cooling. This improved energy efficiency not only reduces operational costs but also contributes to a building's overall sustainability profile.

Additionally, the durability and low maintenance requirements of these panels translate to reduced upkeep costs over the life of the building. Their resistance to corrosion and weathering means they maintain their appearance and performance for many years, reducing the need for frequent repairs or replacements.

Conclusion

10 cm sandwich panels represent a pinnacle of building material technology, offering a unique combination of durability, insulation, and aesthetic appeal. Thanks to their adaptability and enduring advantages, these panels serve as a strong option for diverse construction projects, including housing developments and expansive industrial buildings. As the construction field advances toward greener and more energy-conscious methods, such panels are expected to become more central in the development of future architectural designs.

For more information about our 10 cm sandwich panels and other exterior cladding and facade solutions, please don't hesitate to contact us at info@sdqsc.com. Our experienced team is here to help you identify the ideal solution tailored to your construction requirements.