In the ever-evolving world of construction and renovation, prefabricated thermal panels have emerged as a game-changing solution. These innovative building materials offer a perfect blend of efficiency, durability, and aesthetic appeal, making them an ideal choice for both new construction projects and building renovations. As a leading prefabricated thermal panels manufacturer, Weifang Sandong Building Materials Co., Ltd. is at the forefront of this revolution, providing high-quality products that are transforming the industry.

Understanding Prefabricated Thermal Panels

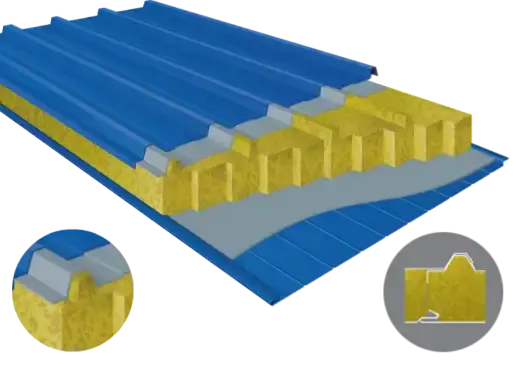

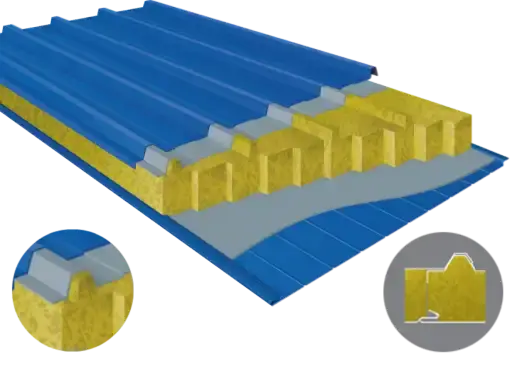

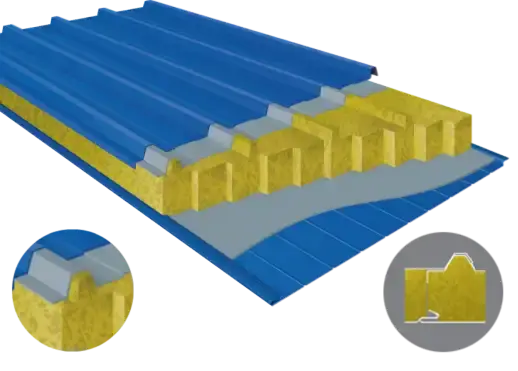

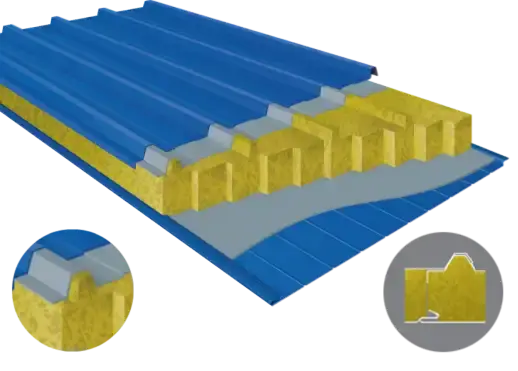

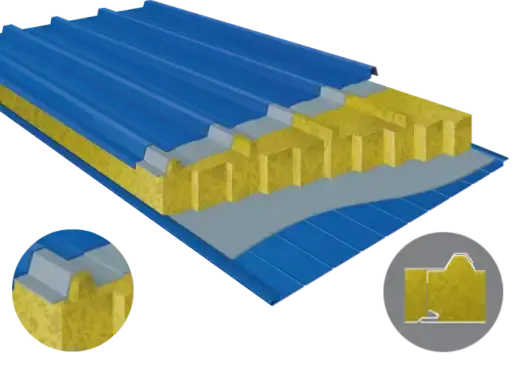

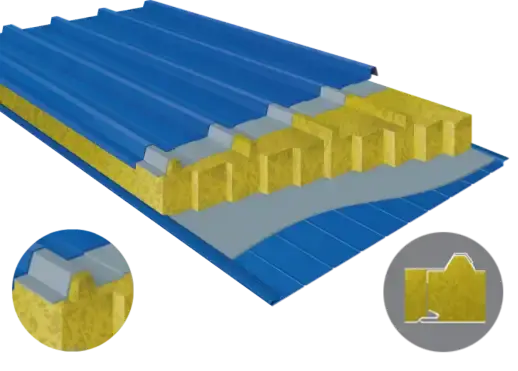

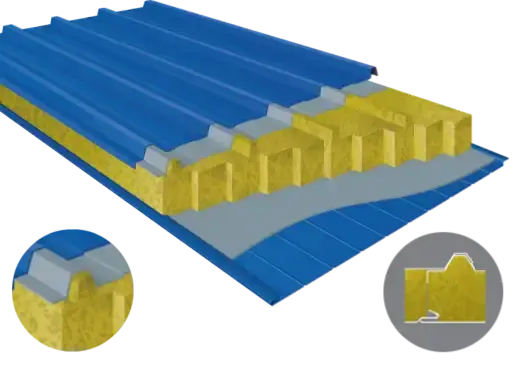

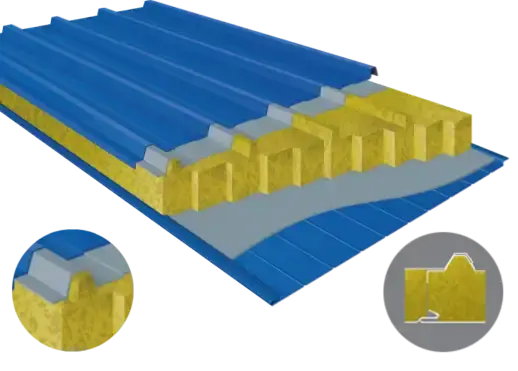

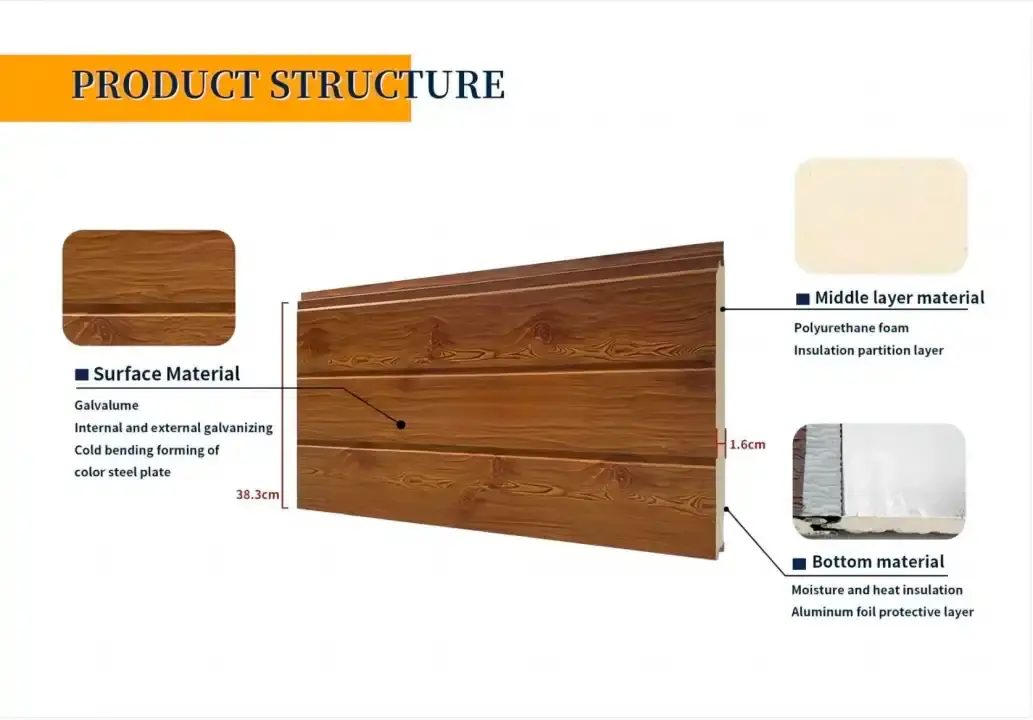

Prefabricated thermal panels are factory-built units designed to provide superior insulation and structural support for buildings. These panels consist of a core insulation material sandwiched between two layers of durable facing material, typically metal or composite. The result is a versatile, energy-efficient building component that can be easily installed in various construction applications.

Composition and Materials

Prefabricated thermal panels are crafted using a variety of materials to suit different project requirements. The core insulation can be made from polyurethane, polystyrene, rock wool, or glass wool, each offering unique thermal properties. The outer facings are typically constructed from aluminum, steel, or stainless steel, providing strength and weather resistance. At Weifang Sandong Building Materials Co., Ltd., our prefabricated thermal panels are available in customizable sizes up to 12 feet long and thickness options ranging from 1 to 4 inches.

Key Features and Benefits

The advantages of using prefabricated thermal panels are numerous and make them a highly attractive solution in modern construction. These panels offer exceptional thermal efficiency, helping to maintain consistent indoor temperatures—keeping buildings warm during winter and cool in summer—which translates to significant energy savings and reduced utility costs. In addition, many panels achieve a Class A fire safety rating, providing enhanced protection for occupants. Their corrosion and UV resistance make them suitable for a wide variety of environmental conditions, while the ease of installation, lightweight design, and minimal maintenance requirements further enhance their appeal for both new construction and renovation projects.

Applications in Building Renovation

Prefabricated thermal panels have revolutionized the building renovation sector, offering a quick and efficient way to upgrade existing structures. Their versatility makes them suitable for a wide range of applications, from residential homes to commercial buildings and industrial facilities.

Exterior Wall Renovation

One of the most common applications of prefabricated thermal panels is in exterior wall renovation. These panels can be easily attached to existing wall structures, providing an instant upgrade in terms of insulation and aesthetic appeal. The wide range of colors and finishes available allows for seamless integration with various architectural styles. Moreover, the durability of these panels ensures long-lasting protection against harsh weather conditions, reducing the need for frequent maintenance and repairs.

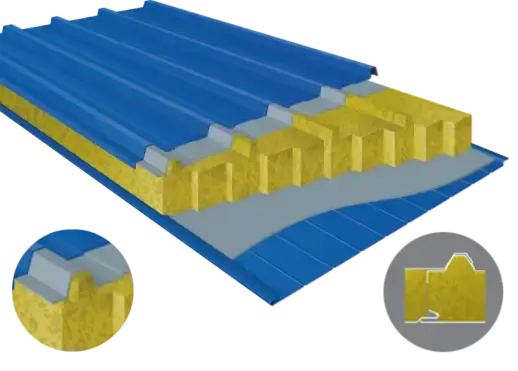

Roof Insulation and Upgrade

Prefabricated thermal panels are also excellent for roof renovations. They can be installed over existing roof structures to enhance insulation and improve overall energy efficiency. The lightweight nature of these prefabricated thermal panels minimizes additional load on the building structure, making them compatible with a wide range of roof types, including both flat and sloped designs. In addition to reducing structural stress, their weather-resistant properties provide enhanced protection against rain, snow, and moisture intrusion, helping to prevent leaks and water damage. This combination of lightness and durability ensures long-term performance and reliability in diverse environmental conditions.

Cost-Effectiveness of Prefabricated Thermal Panels

While the initial cost of prefabricated thermal panels may be higher than some traditional building materials, their long-term cost-effectiveness is undeniable. Several factors contribute to their economic viability in building renovation projects.

Energy Savings

The superior insulation properties of prefabricated thermal panels contribute to substantial reductions in energy consumption, enhancing the overall energy efficiency of buildings. Renovated or newly constructed structures equipped with these panels require less heating during cold months and less cooling during hot seasons, which directly translates into lower energy bills. Over time, the cumulative savings on utility costs can offset the initial investment, making prefabricated thermal panels a smart, cost-effective choice for energy-conscious property owners seeking both comfort and sustainability.

Reduced Labor and Installation Costs

The modular nature of prefabricated thermal panels allows for quick and easy installation, reducing labor costs and project timelines. Unlike traditional renovation methods that may require extensive on-site work, these panels can be rapidly assembled, minimizing disruption to building occupants. This efficiency is particularly valuable in commercial renovation projects where downtime can be costly.

Longevity and Low Maintenance

Prefabricated thermal panels are engineered for long-term performance and built to withstand the rigors of various environmental conditions. Many manufacturers provide warranties of 20 years or more, reflecting the panels’ exceptional durability and reliability. Their resistance to corrosion, UV exposure, and moisture reduces the likelihood of structural damage, minimizing the need for frequent repairs or replacements. Over the lifespan of a building, this longevity, combined with minimal maintenance requirements, translates into significant cost savings, making prefabricated thermal panels an economical and sustainable choice for both residential and commercial construction projects.

Conclusion

Prefabricated thermal panels represent a significant advancement in building technology, offering a cost-effective and efficient solution for renovation projects. Their superior insulation properties, durability, and ease of installation make them an attractive option for property owners looking to upgrade their buildings' energy efficiency and aesthetic appeal. As the construction industry continues to evolve, these innovative panels are poised to play an increasingly important role in creating sustainable, comfortable, and visually appealing structures.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing high-quality prefabricated thermal panels that meet the diverse needs of our clients. Whether you're planning a small residential renovation or a large-scale commercial project, our expert team is ready to help you find the perfect solution. Experience the future of building renovation with our innovative products. Contact us today at info@sdqsc.com to learn more about how our prefabricated thermal panels can transform your next project.

FAQ

How long do prefabricated thermal panels typically last?

With proper installation and maintenance, prefabricated thermal panels can last 30 years or more, depending on the specific product and environmental conditions.

Can prefabricated thermal panels be used in both cold and hot climates?

Yes, these panels are designed to provide excellent insulation in both cold and hot climates, helping to maintain comfortable indoor temperatures year-round.

Are prefabricated thermal panels environmentally friendly?

Many prefabricated thermal panels are made with recyclable materials and contribute to energy efficiency, making them a more environmentally friendly option compared to traditional building materials.

References

1. U.S. Department of Energy. (2023). Insulation Materials. Office of Energy Efficiency & Renewable Energy.

2. International Code Council. (2021). International Energy Conservation Code.

3. Architectural Record. (2022). Innovations in Building Envelope Technology.

4. Journal of Building Engineering. (2023). Advances in Prefabricated Construction Materials.