The Evolution of Building Materials: Introducing Metal Sheet PU Sandwich Panels

The construction industry has witnessed a significant transformation in recent years, with a growing emphasis on sustainable and energy-efficient building materials. Among these innovations, metal sheet PU sandwich panels have emerged as a frontrunner, revolutionizing the way we approach eco-conscious construction.

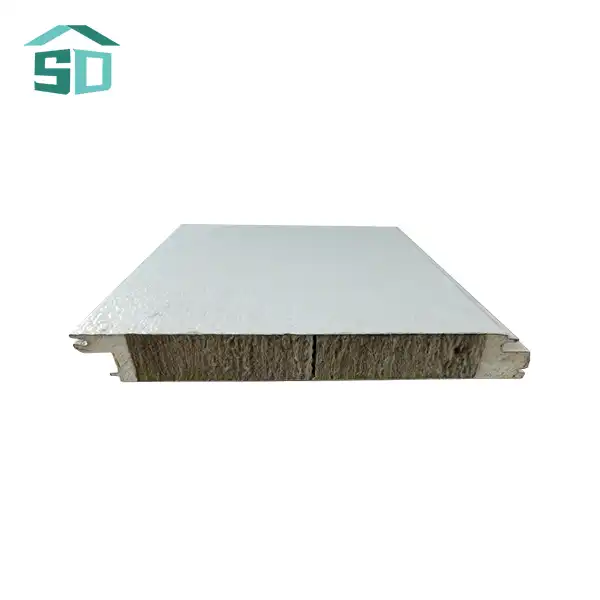

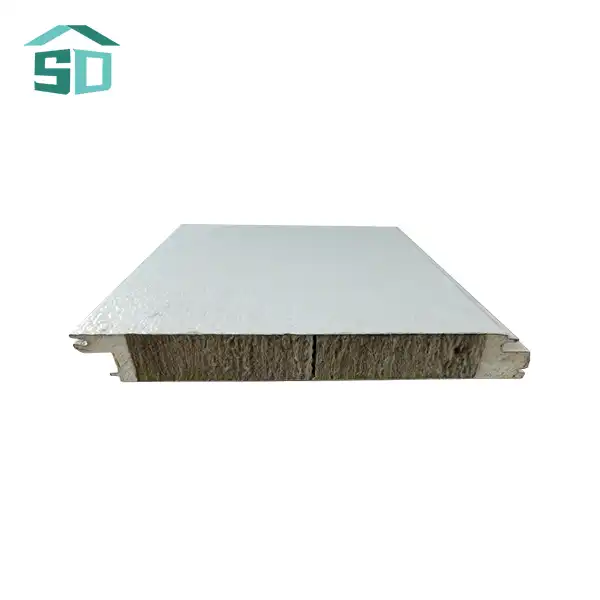

Metal sheet PU sandwich panels are a composite material consisting of two metal sheets bonded to a polyurethane (PU) foam core. This unique combination results in a product that offers exceptional strength, thermal insulation, and versatility. The metal sheets provide durability and weather resistance, while the PU core delivers outstanding insulation properties.

Composition and Manufacturing Process

The manufacturing process of metal sheet PU sandwich panels involves several key steps:

1.Metal Sheet Preparation: High-quality steel or aluminum sheets are selected and treated for corrosion resistance.

2.PU Foam Injection: A specialized polyurethane mixture is injected between the metal sheets, expanding to fill the space.

3.Curing: The panels undergo a controlled curing process to ensure proper bonding and foam density.

4.Quality Control: Rigorous testing is performed to verify thickness, mechanical strength, and fire resistance.

At Weifang Sandong Building Materials Co., Ltd., we utilize advanced production lines and a stringent quality control system to ensure the highest standards in our metal sheet PU sandwich panels. Our comprehensive inspections cover various aspects, including product thickness, paint film thickness, mechanical strength, flame retardancy, and overall appearance.

Key Features and Benefits

Metal sheet PU sandwich panels offer a myriad of advantages that make them an attractive option for sustainable construction:

- Superior Insulation: With a thermal conductivity of 0.018W/m.k and thermal resistance of 2.09m2k/w, these panels provide exceptional energy efficiency.

- Durability: The metal-PU fusion results in long-lasting stability and resistance to environmental factors.

- Fire Resistance: Boasting a fire-protection rating of B1/B2, these panels contribute to safer building designs.

- Weather Resistance: A waterproof rate of 0.0008 and wind resistance of 8.0 Kpa ensure protection against harsh weather conditions.

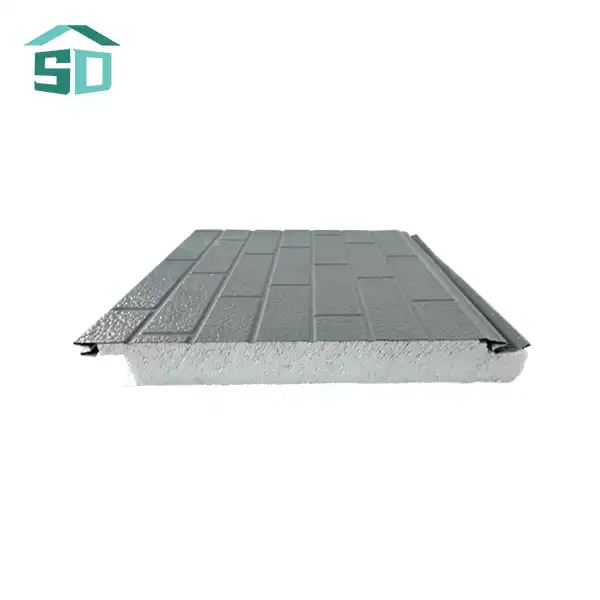

- Customizable: Available in various colors and patterns, these panels can enhance any architectural design.

- Versatility: Suitable for both interior (10mm thickness) and exterior (16mm/20mm thickness) applications.

Environmental Impact and Sustainability of Metal Sheet PU Sandwich Panels

As the construction industry pivots towards more sustainable practices, the environmental impact of building materials has come under increased scrutiny. Metal sheet PU sandwich panels have emerged as a beacon of eco-friendliness, offering numerous benefits that align with green building principles.

Energy Efficiency and Reduced Carbon Footprint

One of the most significant environmental advantages of metal sheet PU sandwich panels lies in their exceptional insulation properties. With a thermal conductivity of just 0.018W/m.k, these panels dramatically reduce the energy required for heating and cooling buildings. This translates to lower energy consumption and, consequently, a reduced carbon footprint over the lifespan of the structure.

Moreover, the thermal resistance of 2.09m2k/w ensures that indoor temperatures remain stable, further minimizing the need for artificial climate control. By helping maintain comfortable interior environments with less energy input, these panels contribute to the overall sustainability of buildings and support efforts to combat climate change.

Longevity and Reduced Waste

The durability of metal sheet PU sandwich panels is another key factor in their environmental appeal. With a compressive strength of 52.7kpa and excellent resistance to corrosion and weathering, these panels have a significantly longer lifespan compared to many traditional building materials. This longevity translates to reduced waste and less frequent need for replacements or repairs, aligning with the principles of sustainable resource management.

Furthermore, the panels' resistance to moisture (with a waterproof rate of 0.0008) and wind (resistance up to 8.0 Kpa) ensures they maintain their integrity and performance over time, even in challenging environmental conditions. This durability not only reduces waste but also minimizes the environmental impact associated with manufacturing and transporting replacement materials.

Recyclability and End-of-Life Considerations

While the long lifespan of metal sheet PU sandwich panels already contributes to waste reduction, their potential for recycling further enhances their environmental credentials. The metal components of the panels are highly recyclable, capable of being repurposed into new products without significant loss of quality.

Although recycling the polyurethane core presents more challenges, ongoing research and technological advancements are improving the recyclability of PU foam. Some innovative processes allow for the chemical breakdown of PU into its constituent parts, which can then be used to create new materials.

Applications and Future Trends in Sustainable Construction

The versatility and eco-friendly properties of metal sheet PU sandwich panels have propelled them to the forefront of sustainable construction. Their applications span a wide range of building types and architectural styles, showcasing their adaptability and potential to reshape the construction landscape.

Diverse Applications in Modern Architecture

Metal sheet PU sandwich panels find application in numerous construction projects, including:

- Residential Complexes: Providing energy-efficient and aesthetically pleasing façades for multi-unit dwellings.

- Office Buildings: Offering superior insulation and sleek, modern exteriors for commercial spaces.

- Industrial Facilities: Ensuring durability and temperature control in warehouses and manufacturing plants.

- Educational Institutions: Creating comfortable learning environments while reducing energy costs.

- Healthcare Facilities: Maintaining strict hygiene standards and temperature control in hospitals and clinics.

- Retail Spaces: Allowing for customizable designs that attract customers while maintaining energy efficiency.

The adaptability of these panels extends to various architectural styles, from contemporary minimalist designs to more traditional aesthetics. With customizable colors and patterns, architects can achieve their desired visual impact while benefiting from the panels' sustainable properties.

Integration with Smart Building Technologies

As the construction industry embraces digital transformation, metal sheet PU sandwich panels are poised to play a crucial role in smart building design. Their excellent insulation properties complement smart HVAC systems, allowing for more precise and efficient temperature control. This synergy between advanced building materials and smart technologies can lead to even greater energy savings and improved occupant comfort.

Furthermore, the potential integration of sensors within or on the surface of these panels could provide real-time data on building performance, enabling proactive maintenance and optimization of energy use. This fusion of sustainable materials with intelligent systems represents the future of eco-conscious construction.

Innovations on the Horizon

The field of sustainable construction materials is continuously evolving, and metal sheet PU sandwich panels are no exception. Ongoing research and development efforts are focused on several areas:

- Enhanced Recycling Techniques: Developing more efficient methods for separating and recycling the components of sandwich panels at the end of their lifecycle.

- Bio-based Polyurethane: Exploring the use of plant-based polyols in PU foam production to reduce reliance on petrochemicals.

- Self-cleaning Surfaces: Incorporating nanotechnology to create panels with self-cleaning properties, reducing maintenance needs and extending lifespans.

- Energy Harvesting: Investigating the potential for integrating photovoltaic cells or other energy-harvesting technologies directly into the panel structure.

Conclusion

Metal sheet PU sandwich panels represent a significant leap forward in sustainable building materials. Their combination of durability, energy efficiency, and versatility makes them an ideal choice for eco-conscious construction projects across various sectors. As the industry continues to prioritize environmental responsibility, these innovative panels are poised to play an increasingly important role in shaping the future of sustainable architecture.

For those looking to embrace the benefits of metal sheet PU sandwich panels in their next construction project, Weifang Sandong Building Materials Co., Ltd. offers a range of high-quality, customizable options. Our commitment to sustainability, coupled with our expertise in exterior cladding and facade solutions, ensures that we can provide the perfect solution for your eco-friendly building needs. To learn more about our products and how they can contribute to your sustainable construction goals, please contact us at info@sdqsc.com.

References

1.Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77–86.

2.Asdrubali, F., D'Alessandro, F., & Schiavoni, S. (2015). A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies, 4, 1–17.

3.Zhou, X., & Zheng, X. (2020). Thermal insulation performance of polyurethane sandwich panels used in building envelope. Journal of Building Engineering, 30, 101280.

4.Cai, W., Wu, Y., Zhong, Y., & Ren, H. (2016). China building energy consumption: Situation, challenges and corresponding measures. Energy Policy, 102, 460–469.

5.Mistriotis, A., & Lagoudi, A. (2019). Assessment of polyurethane foam panels' environmental impact in building applications using Life Cycle Assessment (LCA). Journal of Cleaner Production, 237, 117715.

6.Gupta, A., & Kumar, R. (2019). Emerging trends in building integrated photovoltaic systems: A review. Energy and Buildings, 202, 109363.