The Science Behind Sandwich Wall Panels: Understanding Their Composition and Benefits

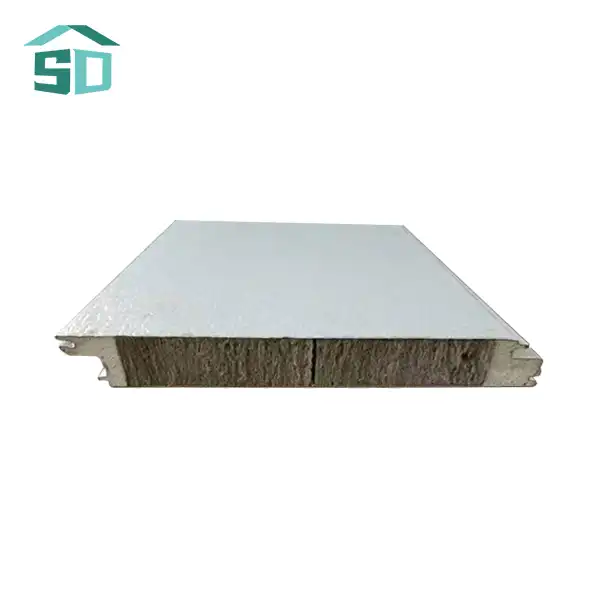

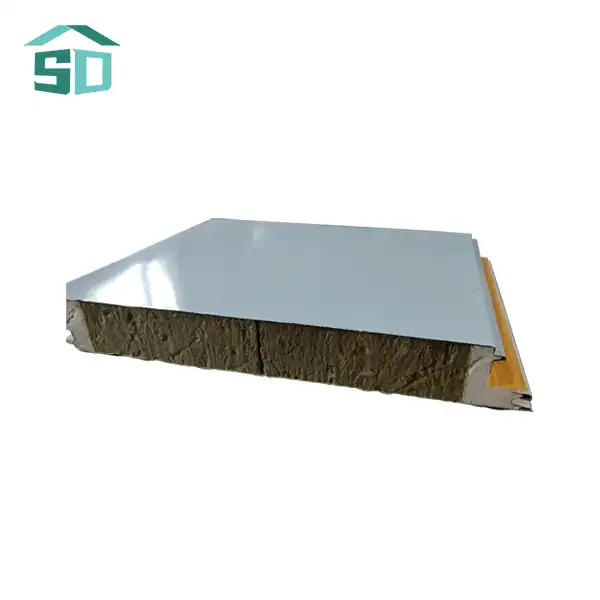

Sandwich wall panels are engineered to provide maximum insulation and structural integrity. These panels consist of three key components: two outer layers, typically made of metal such as aluminum or steel, and an inner core of insulating material. This unique construction offers several advantages for cold storage applications:

Insulation Excellence

The core of sandwich panels is composed of high-performance insulation materials like polyurethane, polystyrene, rock wool, or glass wool. These materials possess exceptional thermal properties, effectively minimizing heat transfer between the interior and exterior environments. The thickness of the panels, ranging from 50mm to 200mm, can be customized to meet specific insulation requirements, ensuring optimal temperature control in cold storage facilities.

Structural Strength

The outer metal layers of sandwich panels contribute to their remarkable strength and durability. These layers, available in materials such as aluminum, steel, stainless steel, or copper, provide excellent resistance to mechanical stress and environmental factors. The robust construction ensures longevity and stability, making sandwich panels an ideal choice for cold storage applications where structural integrity is paramount.

Moisture Resistance

Cold storage environments are prone to condensation and moisture-related issues. Sandwich wall panels are designed to combat these challenges effectively. The outer metal layers act as a barrier against moisture infiltration, while the insulation core helps prevent condensation by maintaining a consistent temperature gradient. This moisture resistance is crucial for preserving the quality of stored goods and maintaining hygienic conditions in cold storage facilities.

Enhancing Energy Efficiency and Temperature Control in Cold Storage Facilities

One of the primary concerns in cold storage operations is maintaining consistent temperatures while minimizing energy consumption. Sandwich panels for walls excel in this aspect, offering several features that contribute to enhanced energy efficiency and precise temperature control:

Superior Thermal Performance

The advanced insulation materials used in sandwich panels, such as polyurethane and polystyrene, boast impressive R-values, indicating their ability to resist heat flow. This superior thermal performance translates to reduced energy requirements for cooling systems, as the panels effectively minimize heat gain from the external environment. By maintaining stable internal temperatures, sandwich panels help cold storage facilities operate more efficiently and cost-effectively.

Airtight Sealing

Sandwich wall panels are designed with interlocking joints and sealing systems that create an airtight envelope around the cold storage space. This tight seal prevents air leakage and infiltration, which are common sources of energy loss in traditional construction methods. By eliminating thermal bridges and air gaps, sandwich panels ensure that the desired temperature is maintained with minimal energy input, resulting in significant cost savings over time.

Thermal Mass Properties

The composite structure of sandwich panels provides a degree of thermal mass, which helps stabilize internal temperatures. This property is particularly beneficial in cold storage applications, as it reduces temperature fluctuations caused by external factors or intermittent door openings. The thermal mass of the panels acts as a buffer, absorbing and releasing heat slowly, thus maintaining a more consistent internal environment and reducing the workload on cooling systems.

Customization and Versatility: Tailoring Sandwich Panels for Specific Cold Storage Needs

Sandwich panels for walls offer a high degree of customization, allowing them to be tailored to meet the unique requirements of various cold storage applications. This versatility makes them an excellent choice for a wide range of industries, from food and beverage to pharmaceuticals and beyond:

Size and Thickness Options

Sandwich panels are available in custom sizes to accommodate different cold storage facility layouts and dimensions. The thickness of the panels can be adjusted to achieve the desired insulation performance, with options ranging from 50mm to 200mm. This flexibility ensures that the panels can be optimized for specific temperature requirements and energy efficiency goals.

Material Selection

The outer layers of sandwich panels for walls can be manufactured using various materials, including aluminum, steel, stainless steel, and copper. Each material offers unique properties in terms of durability, corrosion resistance, and hygiene. For example, stainless steel panels may be preferred in food processing environments due to their ease of cleaning and resistance to bacterial growth.

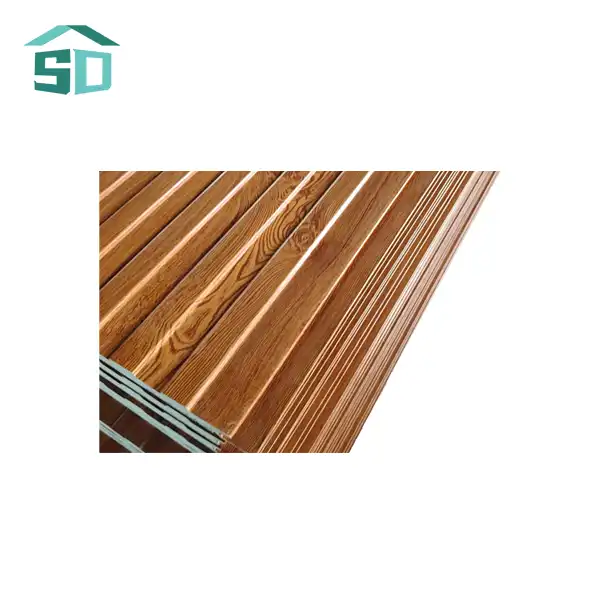

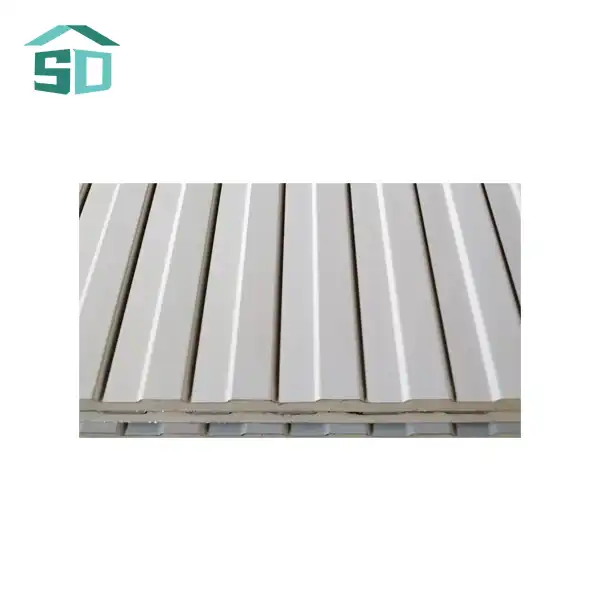

Finish and Color Options

Sandwich wall panels can be customized with various finishes and colors to meet aesthetic requirements or comply with branding guidelines. Options include coating, painting, or anodizing, allowing for a wide range of visual appearances. This customization extends beyond mere aesthetics, as certain finishes can enhance the panels' resistance to UV radiation or chemical exposure, further improving their longevity in specific cold storage environments.

Specialized Features

Manufacturers can incorporate additional features into sandwich panels to address specific cold storage needs. These may include antimicrobial coatings for food safety applications, reinforced cores for high-impact areas, or specialized joints for modular and expandable cold storage solutions. Such customizations ensure that sandwich panels can be optimized for the unique challenges of different cold storage facilities.

Conclusion

Sandwich panels for walls represent the pinnacle of cold storage solutions, offering a perfect blend of insulation efficiency, structural integrity, and customization options. Their advanced composition and versatile design make them ideal for a wide range of cold storage applications, from small-scale refrigeration units to large industrial freezers. By choosing sandwich wall panels, facility managers can ensure optimal temperature control, energy efficiency, and longevity for their cold storage installations.

As the demand for efficient and sustainable cold storage solutions continues to grow, sandwich panels stand out as a future-proof investment. Their ability to meet stringent regulatory requirements, including fire safety standards and energy efficiency regulations, positions them as a reliable choice for modern cold storage facilities.

To explore how sandwich panels can revolutionize your cold storage operations, or to learn more about our extensive range of exterior cladding and facade solutions, we invite you to contact Weifang Sandong Building Materials Co., Ltd. Our team of experts is ready to assist you in finding the perfect sandwich panel solution for your specific needs. Reach out to us at info@sdqsc.com to start your journey towards more efficient and effective cold storage.