Understanding Insulated Steel Siding Panels and Their Role in Building Insulation

Insulated steel siding panels have revolutionized the way we approach building insulation, especially for metal structures. These panels combine the durability of steel with high-performance insulation materials, creating a robust and energy-efficient solution for exterior cladding.

Composition and Design

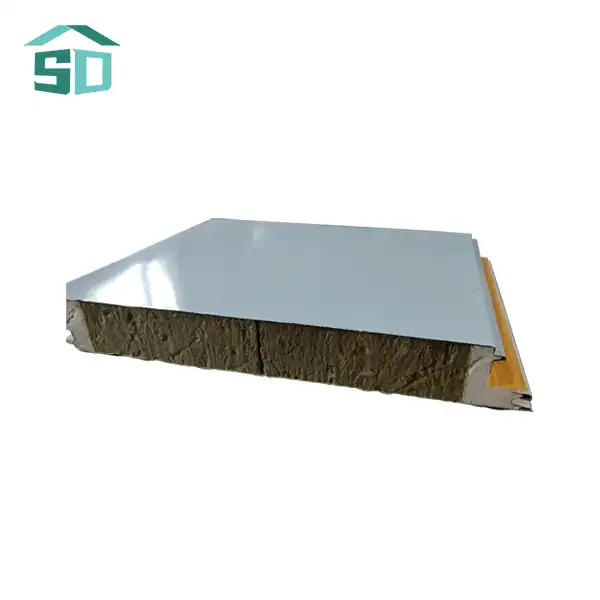

The typical insulated steel siding panel consists of three main components:

- Exterior steel face: Provides weather resistance and structural integrity

- Insulation core: Usually made of polyurethane, polystyrene, or rock wool

- Interior steel face: Adds strength and creates a finished interior appearance

This sandwich-like construction allows for excellent thermal performance without the need for additional layers or air gaps in most applications. The insulation core is firmly bonded between the steel faces, eliminating potential air pockets that could compromise insulation effectiveness.

Thermal Performance

One of the key advantages of insulated steel siding panels is their superior R-value. The R-value is a measure of thermal resistance, indicating how well a material insulates. These panels offer R-values ranging from R-7 to R-32, depending on the thickness and type of insulation used. This high thermal performance is achieved without relying on air gaps, making them an efficient choice for metal building insulation.

Moisture Management

Insulated steel siding panels are designed to manage moisture effectively. The steel faces act as vapor barriers, while the insulation core helps prevent condensation by maintaining a consistent temperature throughout the panel. This integrated approach to moisture control often eliminates the need for additional air gaps in standard applications.

Factors Influencing the Need for an Air Gap

While insulated steel siding panels are highly effective on their own, certain factors may warrant the consideration of an air gap:

Climate Conditions

In areas experiencing extreme temperature shifts or consistently high humidity, incorporating an air gap behind insulated steel siding panels becomes especially beneficial. The air gap enhances natural ventilation and helps regulate internal moisture by promoting airflow. This reduces the risk of condensation, mold growth, and structural deterioration over time, thereby improving building durability.

Building Use

The functional purpose of a metal building plays a key role in determining the need for an air gap. Facilities generating significant internal moisture—such as laundries, greenhouses, swimming pools, or industrial sites—require effective moisture control. An air gap enhances ventilation, prevents condensation buildup, and safeguards sensitive equipment, finishes, and structural components from moisture-related damage.

Local Building Codes

Building regulations vary by jurisdiction and often specify requirements based on regional climate conditions. In certain zones, air gaps may be mandated to meet thermal and moisture management standards. Consulting local building authorities or a qualified architect ensures that your construction project adheres to legal codes and avoids costly redesigns or compliance issues later on.

Existing Moisture Issues

If the structure already shows signs of water damage—such as rust, mildew, or insulation degradation—adding an air gap during retrofitting or panel installation can significantly help. This design feature promotes evaporation and moisture escape, breaking the cycle of condensation and enhancing long-term protection against further deterioration of the building envelope.

Installation Considerations for Insulated Steel Siding Panels

Proper installation is crucial for maximizing the performance of insulated steel siding panels, whether or not an air gap is included.

Surface Preparation

Before installing insulated steel siding panels, it's vital to ensure that the wall surface is thoroughly cleaned, dry, and free of dust, grease, or debris. Proper surface preparation promotes strong adhesion, minimizes installation errors, and is key to achieving a tight seal that ensures maximum thermal insulation and long-term performance.

Panel Alignment and Fastening

Precise panel alignment is critical to achieving a uniform exterior appearance and maintaining continuous insulation. Misalignment can lead to thermal bridging or leaks. Always use manufacturer-recommended fasteners, and ensure they're correctly spaced and securely tightened to prevent shifting, enhance wind resistance, and extend the longevity of the installation.

Sealing and Weatherproofing

Thoroughly seal all seams, joints, and penetrations using high-performance, weather-resistant sealants. This process prevents water infiltration, air leaks, and heat loss, which can compromise energy efficiency. Proper sealing also guards against mold growth and corrosion, helping maintain the structural integrity of both the panels and the underlying wall system.

Trim and Accessories

Choose trim pieces and accessories that are fully compatible with the insulated steel siding panels to ensure a cohesive and functional installation. These components not only provide a clean, professional finish but also protect vulnerable panel edges, corners, and junctions from rain, wind, and other environmental stressors. When correctly installed, trims and accessories reinforce the overall weatherproofing of the building envelope, enhance durability, and maintain the long-term performance of the insulated panels.

Incorporating an Air Gap (If Necessary)

When climate conditions or building usage demand extra moisture control, an air gap can be introduced using furring strips or a secondary framework. This design allows ventilation behind the insulated panels, reducing condensation risks while preserving the panels' insulating function—an effective solution for challenging thermal or humidity conditions.

Conclusion

While insulated steel siding panels are designed to provide excellent insulation without an air gap in most situations, certain circumstances may warrant its inclusion. The decision should be based on a careful assessment of the building's specific needs, climate conditions, and local regulations. By considering these factors and ensuring proper installation, you can create an energy-efficient and durable building envelope that meets your project's requirements.

For expert advice on insulated steel siding panels and their application in your specific project, please don't hesitate to contact us at info@sdqsc.com. Our team of specialists is ready to assist you in optimizing your metal building's insulation strategy.