The Structural Marvels of Honeycomb Sandwich Panels

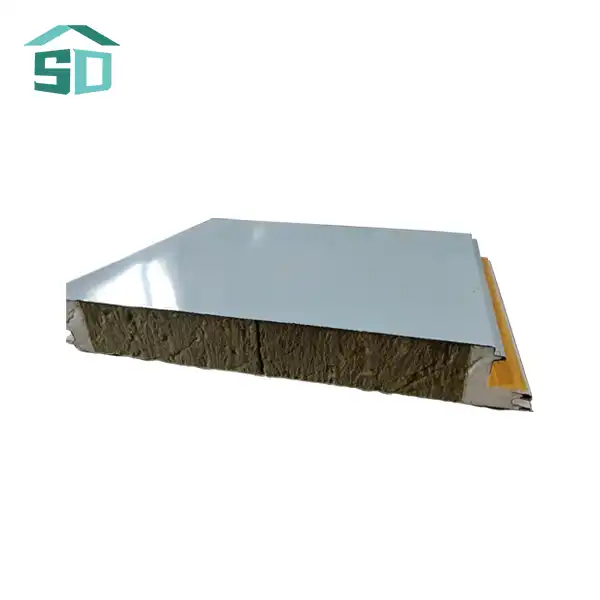

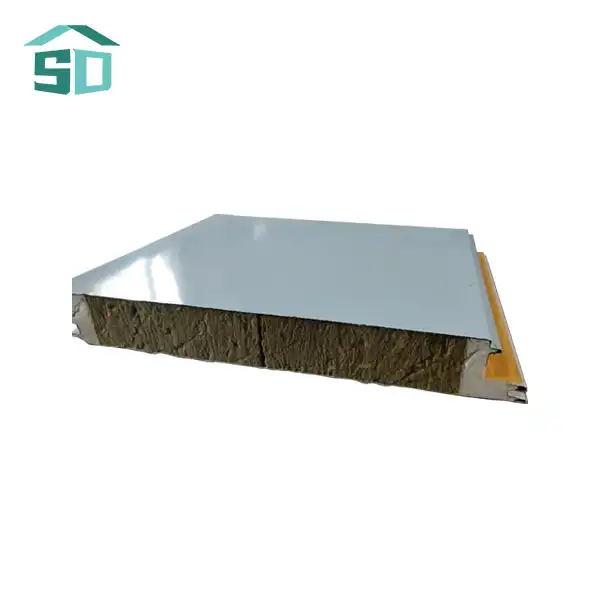

Unveiling the Honeycomb Core

At the heart of honeycomb sandwich panels lies their innovative core structure, which mimics the efficiency of a beehive. This hexagonal pattern is not just aesthetically pleasing but also serves a crucial structural purpose. The honeycomb core, typically crafted from aluminum or aramid fiber, creates a network of interconnected cells that distribute load evenly across the panel. This design allows for maximum strength with minimal material usage, resulting in a lightweight yet incredibly robust panel.

The core's ability to resist compression is particularly noteworthy. When pressure is applied, the honeycomb structure absorbs and disperses the force, preventing localized damage and maintaining the panel's overall integrity. This property makes honeycomb sandwich panels ideal for applications where weight reduction is crucial without compromising on strength, such as in aerospace or marine industries.

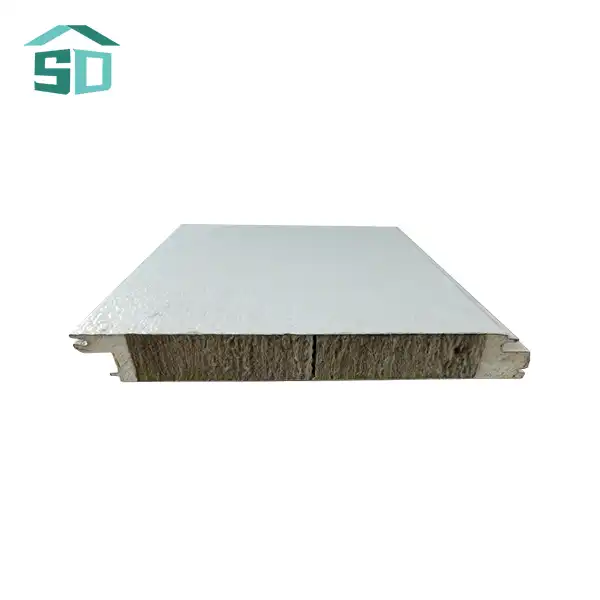

Face Sheets: The Protective Armor

Complementing the honeycomb core are the face sheets, which act as a protective armor for the panel. These sheets are typically made from materials like aluminum, fiber-reinforced composites, or even stainless steel, depending on the specific application requirements. The face sheets not only provide a smooth, finished surface but also contribute significantly to the panel's overall durability.

The face sheets play a vital role in resisting bending and shear forces. When a load is applied to the panel, the face sheets work in tandem with the core to distribute the stress, preventing deformation or failure. Additionally, these outer layers offer protection against environmental factors such as moisture, UV radiation, and chemical exposure, further enhancing the panel's longevity.

Resilience in Diverse Environments

Weathering the Storm: Climate Resistance

One of the standout features of honeycomb sandwich panels is their remarkable resilience in diverse climatic conditions. These panels are engineered to withstand a wide range of temperatures without warping, expanding, or contracting significantly. This thermal stability is crucial for maintaining structural integrity in applications where temperature fluctuations are common, such as building facades or transportation vehicles.

Moreover, honeycomb sandwich panels exhibit excellent resistance to moisture and humidity. The closed-cell structure of the honeycomb core prevents water infiltration, while the face sheets can be treated with water-resistant coatings for added protection. This combination makes these panels highly suitable for use in coastal areas or regions with high rainfall, where traditional materials might succumb to water damage or corrosion.

Standing Strong: Impact and Vibration Resistance

The unique structure of honeycomb sandwich panels also confers impressive impact and vibration resistance. The honeycomb core acts as a natural shock absorber, dissipating energy from impacts across its cellular network. This property is particularly valuable in applications where the panels may be subject to accidental collisions or repeated vibrations, such as in industrial settings or transportation infrastructure.

The panels' ability to dampen vibrations also contributes to their durability by reducing fatigue stress on the material over time. This characteristic makes honeycomb sandwich panels an excellent choice for applications in aerospace, where they must withstand the constant vibrations of flight, or in construction, where they can help mitigate the effects of seismic activity or wind loads on structures.

Longevity Through Innovation

Advanced Materials: Pushing the Boundaries

The durability of honeycomb sandwich panels is continually being enhanced through the use of advanced materials. Researchers and manufacturers are exploring new core materials, such as carbon fiber reinforced polymers or bio-based composites, to further improve strength-to-weight ratios and environmental sustainability. These innovations are pushing the boundaries of what's possible in terms of panel performance and longevity.

Similarly, advancements in face sheet materials and coatings are contributing to increased durability. For instance, the development of nanocomposite coatings can provide enhanced resistance to scratches, UV radiation, and chemical exposure, further extending the lifespan of honeycomb sandwich panels in challenging environments.

Smart Design: Tailoring for Specific Applications

The durability of honeycomb sandwich panels is not just about the materials used; it's also about smart design tailored to specific applications. Manufacturers are increasingly using sophisticated computer modeling and simulation techniques to optimize panel designs for particular use cases. This approach allows for the fine-tuning of core thickness, cell size, and face sheet composition to meet the exact durability requirements of each application.

Furthermore, innovative joining and fastening techniques are being developed to ensure that the panels maintain their integrity when integrated into larger structures. These advancements in assembly methods contribute significantly to the overall durability and longevity of structures incorporating honeycomb sandwich panels.

Conclusion

Honeycomb sandwich panels stand as a testament to modern engineering, offering exceptional durability that meets the demanding requirements of various industries. Their unique structure, combining a lightweight honeycomb core with robust face sheets, provides an unparalleled balance of strength, weight reduction, and longevity. As materials science and manufacturing techniques continue to evolve, we can expect these panels to become even more durable and versatile, opening up new possibilities in construction, transportation, and beyond.

For those seeking to leverage the durability and versatility of honeycomb sandwich panels in their projects, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality solutions. Our expert team is ready to assist you in selecting the perfect panels for your specific needs. To learn more about our products and how they can enhance your project's durability and performance, please contact us at info@sdqsc.com.