The Enduring Durability of Sandwich Panel Walls

Robust Construction for Long-Lasting Performance

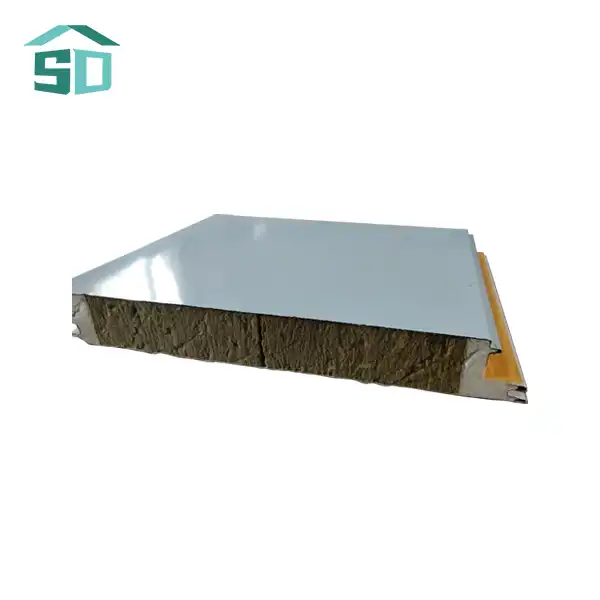

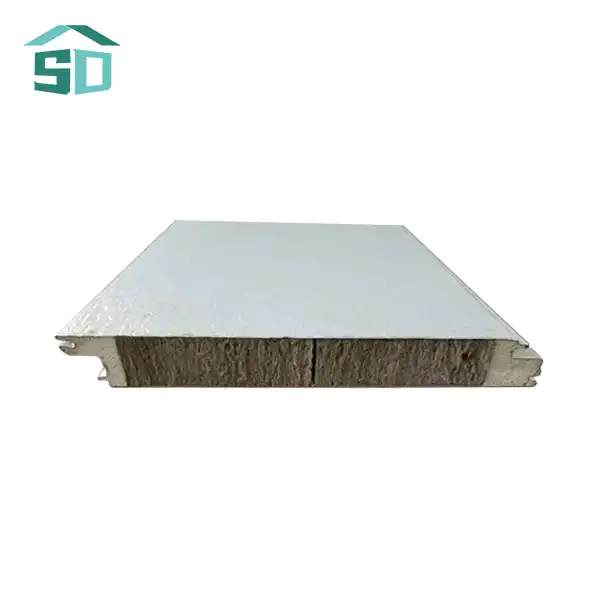

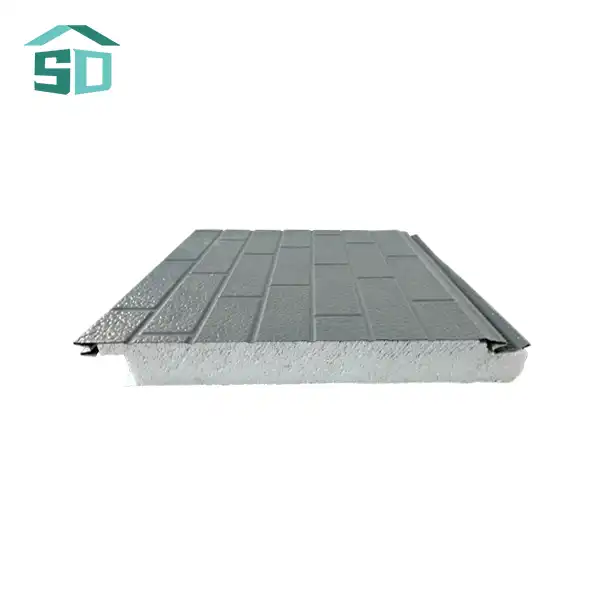

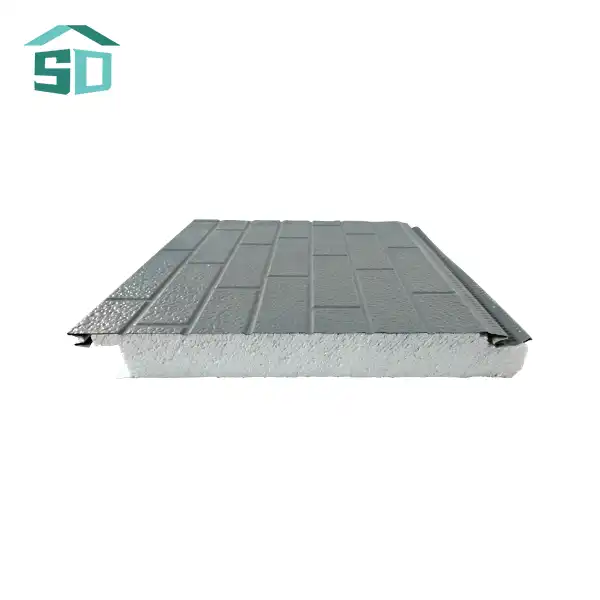

Sandwich panel walls are engineered to withstand the test of time, thanks to their innovative construction. These panels consist of two external layers, typically made of aluminum, galvanized steel, or stainless steel, sandwiching a core of insulation material. This triple-layer design creates a sturdy structure that can resist various environmental factors and maintain its integrity for decades.

The exterior materials used in sandwich panel walls are chosen for their durability and resistance to corrosion. Aluminum panels, for instance, naturally form a protective oxide layer that shields them from rust and deterioration. Galvanized steel panels feature a zinc coating that adds an extra layer of protection against corrosion. In comparison, stainless steel panels exhibit exceptional resistance to rust and wear, which makes them particularly well-suited for demanding or aggressive environmental conditions.

Weather Resistance and Thermal Stability

A crucial aspect of ensuring the lasting effectiveness of sandwich panel walls lies in their resilience to varying environmental elements. Engineered to endure UV exposure, shifting temperatures, and humidity, these panels retain both their strength and visual appeal throughout extended use.

The thermal stability of sandwich panel walls is particularly noteworthy. With thermal conductivity values as low as 0.022 W/mK for polyurethane (PU) insulation and 0.037 W/mK for expanded polystyrene (EPS), these panels provide excellent insulation throughout their lifespan. This thermal efficiency not only contributes to energy savings but also helps maintain a consistent indoor environment, reducing the stress on the building structure caused by thermal expansion and contraction.

Longevity Through Advanced Insulation and Fire Safety

Insulation Materials: A Core of Efficiency

The heart of sandwich panel walls lies in their insulation core, which plays a crucial role in their long-term performance. Common insulation materials include polyurethane (PU), expanded polystyrene (EPS), and rockwool, each offering unique benefits that contribute to the panel's longevity.

Polyurethane insulation, with its low thermal conductivity, provides superior insulation properties that remain stable over time. EPS, known for its moisture resistance and dimensional stability, ensures the panel maintains its insulative properties even in damp conditions. Rockwool, a mineral wool insulation, offers excellent fire resistance and sound insulation, contributing to the overall safety and comfort of the building throughout its lifespan.

Fire Safety: A Long-Term Protection Measure

The fire safety features of sandwich panel walls are a critical aspect of their long-term performance. Panels with rockwool insulation can achieve a fire rating of up to A1, the highest possible classification. This non-combustible nature ensures that the walls maintain their protective properties over time, providing peace of mind for building owners and occupants.

The fire-resistant properties of sandwich panel walls do not degrade over time, unlike some traditional building materials that may become more susceptible to fire as they age. This consistent performance in fire safety is a significant factor in the long-term value and reliability of buildings constructed with these panels.

Aesthetic Longevity and Customization Options

Enduring Visual Appeal

The aesthetic performance of sandwich panel walls over time is another area where they excel. Available in a wide range of colors and surface treatments, these panels can maintain their appearance for many years with minimal maintenance. The use of high-quality PVDF (Polyvinylidene Fluoride) coatings provides excellent color retention and resistance to fading, chalking, and weathering.

Sandwich panel walls can be customized to match various architectural styles and design preferences. With panel thicknesses ranging from 50mm to 150mm and widths of 1000mm or 1200mm, they offer flexibility in design while maintaining their structural and insulative properties. The ability to customize lengths to fit project requirements further enhances their versatility and long-term appeal.

Adaptability and Future-Proofing

The long-term performance of sandwich panel walls is further enhanced by their adaptability. As building needs change over time, these panels can be easily modified or replaced without compromising the overall structure. This flexibility allows buildings to evolve and adapt to new requirements, extending their useful life and maintaining their relevance in changing environments.

Moreover, the eco-conscious nature of sandwich panel walls contributes to their long-term value. As sustainable building practices become increasingly important, the use of recyclable materials and energy-efficient insulation in these panels aligns with future environmental standards, ensuring their continued relevance in the construction industry.

Conclusion

Sandwich panel walls have proven to be a remarkable innovation in the construction industry, demonstrating exceptional performance over time. Their durability, thermal efficiency, fire safety, and aesthetic longevity make them a superior choice for modern building envelopes. As we've explored, these panels not only maintain their structural integrity and insulative properties for decades but also offer the flexibility to adapt to changing needs and environmental standards.

For those seeking a reliable, long-lasting solution for their construction projects, sandwich panel walls present a compelling option. Their ability to combine durability with energy efficiency and aesthetic appeal ensures that buildings not only perform well initially but continue to do so for years to come. If you're interested in learning more about how sandwich panel walls can benefit your next project or have questions about their long-term performance, we invite you to reach out to our team of experts at info@sdqsc.com. Let us help you build for the future with confidence and innovation.