The Power of 10 cm Sandwich Panels: A Perfect Balance of Protection and Performance

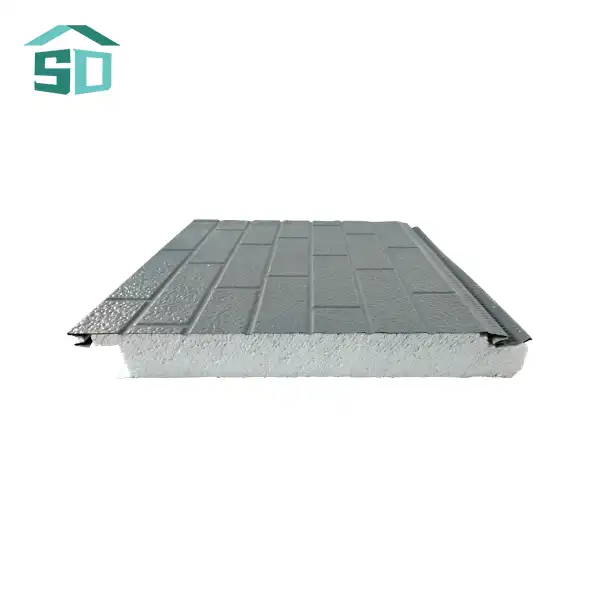

When it comes to sandwich panels, thickness plays a crucial role in determining their overall performance. The 10 cm sandwich panel stands out as an optimal choice, striking a perfect balance between enhanced durability and superior insulation. This thickness ensures that the panel can withstand various environmental stressors while providing excellent thermal resistance.

The sturdy construction of 10 cm sandwich panels contributes significantly to their longevity and strength. With a thickness of 100 mm, these panels offer robust support and stability to structures, making them ideal for both interior and exterior wall enhancements. Their ability to resist deformation under load ensures that buildings maintain their structural integrity over time.

One of the key advantages of the 10 cm sandwich panel is its optimized insulation properties. The substantial thickness allows for a generous layer of insulating material, which can be polyurethane (PU), polystyrene (EPS), or rock wool. This results in superior thermal performance, creating energy-efficient living spaces that require less heating and cooling, thereby reducing energy costs and environmental impact.

Fire Resistance: A Critical Safety Feature

The flame-resistant design of 10 cm sandwich panels is a critical feature that sets them apart. Depending on the insulation material used, these panels can achieve a fire rating of Class A to B. This non-combustible characteristic is essential for safeguarding spaces against fire hazards, making them an excellent choice for buildings where fire safety is a top priority.

The fire-resistant properties of these panels are not just limited to their core material. The metal sheets used in their construction, which can be steel, aluminum, or stainless steel, also contribute to their overall fire performance. This multi-layered approach to fire safety ensures that the panels can withstand high temperatures and slow down the spread of fire, providing valuable time for evacuation in case of emergencies.

Durability and Versatility: Key Attributes of 10 cm Sandwich Panels

The durability of 10 cm sandwich panels extends beyond their fire-resistant properties. These panels are designed to resist corrosion and weathering, making them highly resilient against environmental degradation. This corrosion-free durability ensures that the panels maintain their aesthetic appeal and structural integrity even when exposed to harsh weather conditions.

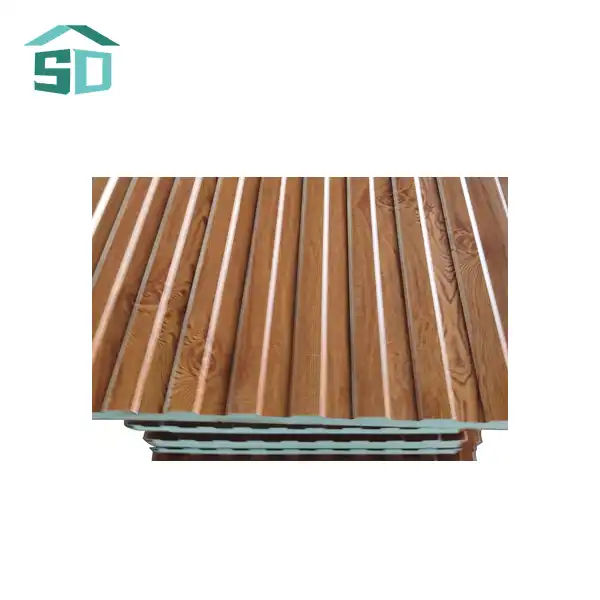

The versatility of 10 cm sandwich panels is another factor that makes them increasingly popular in modern construction. With a width range of 950-1150 mm and lengths of up to 12 meters, these panels can be easily adapted to various architectural designs and building requirements. They are suitable for both interior and exterior applications, offering flexibility in design and installation.

Customization Options for Unique Aesthetics

One of the standout features of 10 cm sandwich panels is the ability to customize their appearance. The panels can be coated, painted, or anodized, allowing for a wide range of surface treatment options. Color customization based on the RAL color chart provides architects and designers with the freedom to create unique and visually appealing facades that complement the overall aesthetic of the building.

This level of customization extends beyond just color choices. The panels can be manufactured with various surface textures and patterns, enabling the creation of distinctive architectural elements. Whether it's a sleek, modern look or a more traditional appearance, 10 cm sandwich panels can be tailored to meet specific design requirements.

Sustainable Building: The Eco-Friendly Advantage of 10 cm Sandwich Panels

In an era where sustainability is increasingly important in construction, 10 cm sandwich panels offer an eco-friendly option. Many of these panels are made from sustainable materials, contributing to green building initiatives. The energy efficiency provided by their excellent insulation properties also plays a significant role in reducing the carbon footprint of buildings over their lifetime.

The manufacturing process of these panels is often designed to minimize waste and energy consumption. Additionally, the longevity and durability of 10 cm sandwich panels mean they need to be replaced less frequently, reducing the overall environmental impact associated with building maintenance and renovation.

Cost-Effectiveness and Long-Term Value

While the initial cost of 10 cm sandwich panels may be higher than some traditional building materials, they offer exceptional value over time. The combination of durability, energy efficiency, and low maintenance requirements results in significant long-term cost savings. Building owners can expect reduced energy bills, lower maintenance costs, and a longer lifespan for their structures.

Moreover, the quick and easy installation process of these panels can lead to substantial savings in construction time and labor costs. Their lightweight nature compared to traditional building materials also means reduced structural load, potentially leading to savings in foundational and support structures.

Conclusion

The 10 cm sandwich panel represents a significant advancement in building technology, offering a unique combination of fire safety, energy efficiency, durability, and aesthetic versatility. As the construction industry continues to evolve towards more sustainable and safe building practices, these panels are poised to play an increasingly important role in shaping the buildings of the future.

For those looking to leverage the benefits of 10 cm sandwich panels in their construction projects, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality options. Our expertise in exterior cladding and facade solutions ensures that you receive products that meet the highest standards of safety and efficiency. To learn more about our 10 cm sandwich panels and other innovative building materials, please contact us at info@sdqsc.com.