The Science Behind Corrugated Sandwich Panels

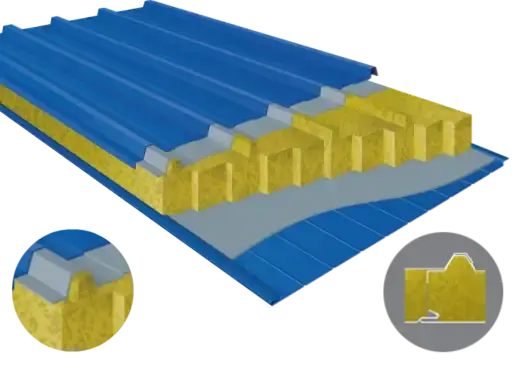

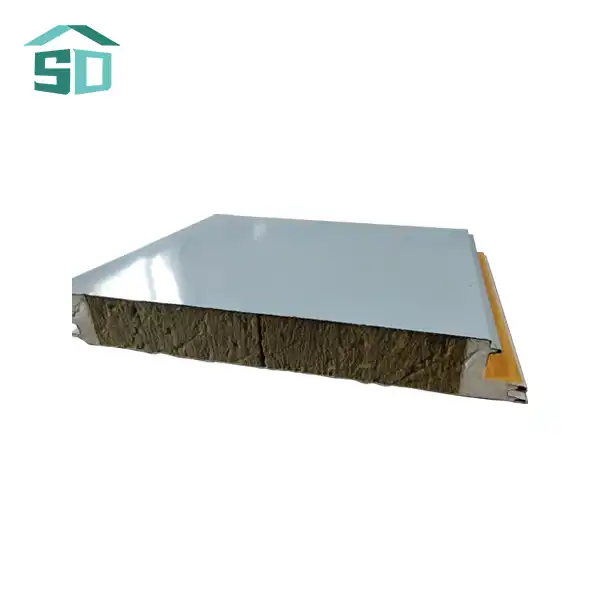

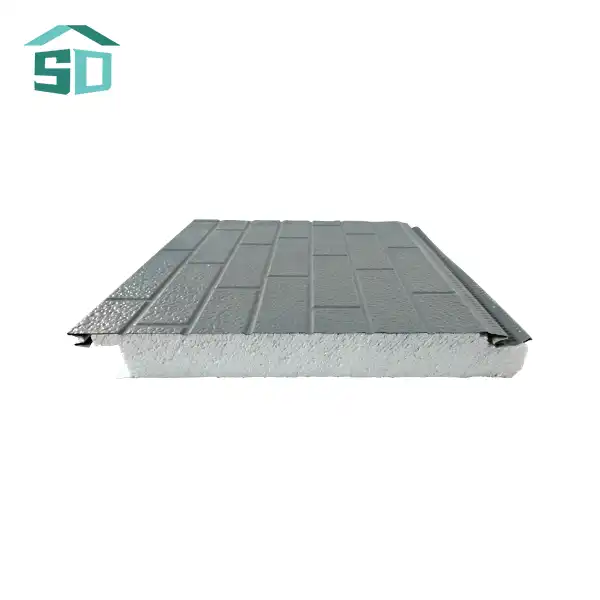

Corrugated sandwich panels are a testament to intelligent engineering and material science. These panels consist of two outer layers, typically made of metal or high-strength materials, with a core of insulating material sandwiched between them. The corrugated design adds an extra dimension of strength and stability to the panel structure.

Understanding the Corrugated Structure

The corrugated design in sandwich panels is characterized by a series of parallel ridges and grooves. This undulating pattern is not just for aesthetic purposes; it plays a crucial role in enhancing the panel's structural integrity. The corrugated sandwich panel's unique design distributes stress more evenly across the surface, significantly increasing its load-bearing capacity.

Material Composition and Its Impact

The choice of materials for corrugated sandwich panels plays a pivotal role in determining their overall performance and longevity. High-quality steel or aluminum is commonly used for the outer layers, offering exceptional strength, durability, and resistance to harsh weather conditions, corrosion, and UV exposure. The core material, usually polyurethane foam or mineral wool, provides outstanding thermal and acoustic insulation. This carefully engineered combination produces corrugated sandwich panels that are not only structurally robust but also highly energy-efficient, making them ideal for industrial, commercial, and residential building applications.

Benefits of Corrugated Designs in Panel Strength

The corrugated design in sandwich panels offers numerous advantages that contribute to their increasing popularity in the construction industry. Let's explore some of the key benefits that make corrugated sandwich panels a preferred choice for builders and architects alike.

Enhanced Load-Bearing Capacity

One of the primary advantages of corrugated sandwich panels is their exceptional load-bearing capacity. The corrugated structure allows for better distribution of weight and stress across the panel. This design enables corrugated sandwich panels to support heavier loads compared to flat panels of similar thickness, making them ideal for roofing and wall applications in large structures.

Improved Flexural Rigidity

Flexural rigidity refers to a material's ability to resist bending or deformation when subjected to external loads. Corrugated sandwich panels demonstrate exceptional flexural rigidity thanks to their distinctive structure. The alternating ridges and valleys of the corrugated design significantly increase the panel’s moment of inertia, enhancing its strength and stiffness. This structural advantage allows the panels to withstand bending and flexing far better than flat sheets. Such superior resistance is especially valuable in applications exposed to wind loads, snow accumulation, or other lateral forces, ensuring structural stability and long-term durability.

Lightweight Yet Strong

Despite their impressive strength and rigidity, corrugated sandwich panels are remarkably lightweight, making them highly practical for construction projects. This advantageous characteristic stems from the efficient use of materials in their design. The corrugated structure maximizes strength and stiffness while minimizing the amount of material required, producing panels that are easy to transport, handle, and install. Additionally, their lightweight nature reduces the overall load on the building’s framework, which can lower costs associated with foundations, structural supports, and labor, while maintaining exceptional durability and performance.

Applications and Future Trends

The versatility and strength of corrugated sandwich panels have led to their widespread adoption across various industries. From construction to transportation, these panels are revolutionizing how we approach structural design and energy efficiency.

Diverse Applications of Corrugated Sandwich Panels

Corrugated sandwich panels find applications in a wide range of sectors. In the construction industry, they are commonly used for roofing, wall cladding, and partitioning in commercial and industrial buildings. The transportation sector utilizes these panels in the manufacture of truck bodies, trailers, and shipping containers, taking advantage of their strength-to-weight ratio. Additionally, corrugated sandwich panels are increasingly being used in the aerospace industry for aircraft interiors and cargo hold linings.

Innovations in Corrugated Sandwich Panel Technology

The field of corrugated sandwich panel technology is continuously evolving. Recent innovations focus on improving the panels' fire resistance, acoustic properties, and sustainability. Some corrugated sandwich panel suppliers are exploring the use of recycled materials in panel production, aligning with the growing demand for eco-friendly building solutions. Furthermore, advancements in manufacturing processes are leading to panels with even greater strength and durability, expanding their potential applications.

The Future of Building with Corrugated Sandwich Panels

As the construction industry moves towards more sustainable and efficient building practices, corrugated sandwich panels are poised to play an increasingly important role. Their combination of strength, insulation properties, and lightweight nature makes them an attractive option for energy-efficient building designs. The future may see the development of smart corrugated sandwich panels integrated with sensors for real-time monitoring of structural health and environmental conditions.

Conclusion

Corrugated sandwich panels represent a significant advancement in building material technology. Their unique design provides exceptional strength, durability, and insulation properties, making them an ideal choice for a wide range of applications. From enhancing load-bearing capacity to improving energy efficiency, these panels offer numerous benefits that are reshaping the construction industry. As technology continues to evolve, we can expect corrugated sandwich panels to play an even more crucial role in shaping the buildings of the future.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality corrugated sandwich panels that meet the diverse needs of our clients. Our panels are designed to offer superior strength, insulation, and aesthetic appeal, suitable for various applications in residential, commercial, and industrial settings. Whether you're planning a new construction project or looking to renovate, our corrugated sandwich panels can provide the perfect solution. For more information about our products and how they can benefit your next project, please contact us at info@sdqsc.com.

FAQ

What makes corrugated sandwich panels energy-efficient?

Corrugated sandwich panels are energy-efficient due to their insulating core material and the air pockets created by the corrugated design, which reduce heat transfer.

Are corrugated sandwich panels suitable for all climate conditions?

Yes, these panels are designed to withstand various weather conditions, from extreme heat to cold, making them suitable for use in diverse climates.

How long do corrugated sandwich panels typically last?

With proper installation and maintenance, corrugated sandwich panels can last for several decades, often exceeding 30 years.

References

1. Davies, J. M. (2001). Lightweight sandwich construction. John Wiley & Sons.

2. Vinson, J. R. (2018). The behavior of sandwich structures of isotropic and composite materials. Routledge.

3. Zenkert, D. (1997). An introduction to sandwich construction. Engineering materials advisory services.

4. Allen, H. G. (2013). Analysis and design of structural sandwich panels. Elsevier.