Understanding the Structure and Benefits of Metal Sheet PU Sandwich Panels

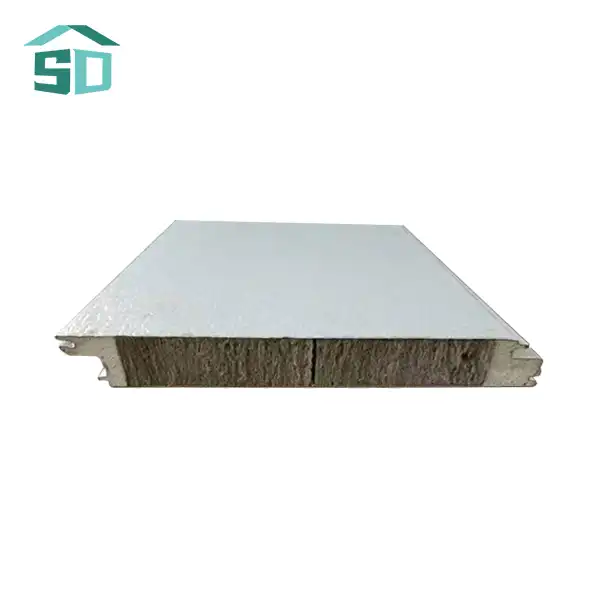

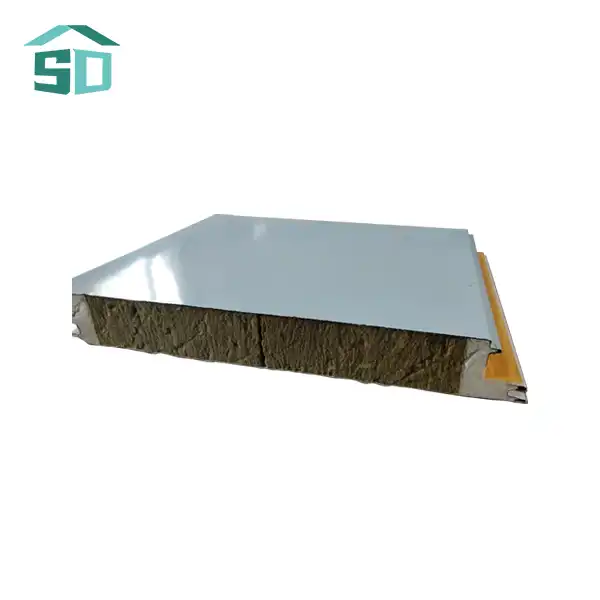

Composition and Design

Metal sheet PU sandwich panels consist of two sturdy metal facings bonded to a high-density polyurethane (PU) foam core, creating a strong yet lightweight composite structure. This unique configuration provides multiple benefits for cold room and industrial insulation applications. The outer metal sheets ensure superior durability, corrosion resistance, and impact protection, while the PU foam core guarantees outstanding thermal insulation and energy efficiency.

When selecting a metal sheet PU sandwich panel supplier, it’s crucial to evaluate factors such as panel thickness, coating quality, and foam density to ensure long-term performance, energy savings, and compliance with safety and hygiene standards in temperature-controlled environments.

Thermal Insulation Properties

One of the primary reasons for choosing metal sheet PU sandwich panels in cold rooms is their superior thermal insulation capabilities. The polyurethane foam core has a low thermal conductivity, which helps maintain consistent temperatures within the cold storage facility. This efficiency directly results in lower heat transfer, leading to significantly reduced energy consumption and long-term operational savings for facilities that rely on temperature control, such as cold storage warehouses or food processing plants.

Additionally, consistent insulation performance contributes to improved system stability and reduced strain on cooling or heating equipment. When evaluating products from a metal sheet PU sandwich supplier, it is essential to carefully review the R-value, as higher ratings indicate superior insulation effectiveness, ensuring better thermal resistance and overall energy efficiency throughout the building’s lifecycle.

Moisture Resistance and Vapor Barrier

Cold rooms are prone to condensation and moisture-related issues. Metal sheet PU sandwich panels offer excellent moisture resistance, thanks to their closed-cell foam structure and vapor-tight metal facings. This feature helps prevent water vapor from penetrating the insulation, reducing the risk of mold growth and maintaining the integrity of stored goods. When selecting panels, ensure that the metal sheet PU sandwich supplier provides products with proven moisture resistance capabilities.

Installation and Maintenance Considerations for Cold Room Applications

Ease of Installation

One of the key advantages of metal sheet PU sandwich panels is their ease of installation. These panels are lightweight yet rigid, making them easier to handle and install compared to traditional insulation methods. Many metal sheet PU sandwich suppliers offer panels with interlocking systems, further simplifying the installation process. This ease of installation can significantly reduce construction time and labor costs for cold room projects.

Joint Sealing and Thermal Bridging

Proper sealing of joints between metal sheet PU sandwich panels is crucial for maintaining the cold room's thermal efficiency. Inadequate sealing can lead to thermal bridging, where heat can bypass the insulation, compromising the overall performance of the cold storage facility. When working with a metal sheet PU sandwich supplier, inquire about their recommended sealing methods and any specialized joint systems they offer to minimize thermal bridging.

Cleaning and Maintenance

The smooth surface of metal sheet PU sandwich panels makes them relatively easy to clean and maintain. This is particularly important in cold storage facilities where hygiene is paramount. Regular cleaning with appropriate cleaning agents can help prevent the buildup of mold and bacteria. When selecting panels from a metal sheet PU sandwich supplier, consider options with food-safe coatings for additional protection in food storage applications.

Regulatory Compliance and Safety Considerations

Fire Safety Standards

Fire safety is a critical consideration in any building project, including cold rooms. Many metal sheet PU sandwich suppliers offer panels with fire-retardant properties to meet stringent safety standards. When selecting panels, verify that they comply with relevant fire safety regulations and have appropriate fire ratings for your specific application.

Energy Efficiency Regulations

As energy efficiency becomes increasingly important, many regions have implemented stricter regulations for cold storage facilities. Metal sheet PU sandwich panels can help meet these requirements due to their excellent insulation properties. When choosing a metal sheet PU sandwich supplier, look for products that meet or exceed local energy efficiency standards to ensure long-term compliance and operational efficiency.

Food Safety Compliance

For cold rooms used in food storage and processing, compliance with food safety regulations is essential. Many metal sheet PU sandwich suppliers offer panels with food-grade surfaces that meet HACCP (Hazard Analysis Critical Control Point) standards. These panels are designed to prevent contamination and support a hygienic environment, making them ideal for use in food-related cold storage applications.

Conclusion

Conclusion

Metal sheet PU sandwich panels offer a versatile and efficient solution for cold room construction, combining durability, insulation, and ease of installation. By carefully considering factors such as thermal performance, moisture resistance, installation methods, and regulatory compliance, you can make informed decisions when selecting panels for your cold storage project. Remember to work with reputable metal sheet PU sandwich suppliers to ensure you receive high-quality products that meet your specific needs.

Are you planning a cold room project and need expert guidance on metal sheet PU sandwich panels? Look no further than Weifang Sandong Building Materials Co., Ltd. Our advanced production lines and rigorous quality control system ensure top-notch products for your cold storage needs. From residential complexes to commercial facilities, our versatile panels offer superior performance and aesthetic appeal. Contact us today at info@sdqsc.com to discover how our exterior cladding solutions can enhance your cold room project.

FAQ

What thickness of metal sheet PU sandwich panels is recommended for cold rooms?

The recommended thickness depends on the specific temperature requirements of your cold room. Generally, panels ranging from 80mm to 200mm are used, with thicker panels providing better insulation for lower temperatures.

How long do metal sheet PU sandwich panels typically last in cold room applications?

With proper installation and maintenance, these panels can last 20-30 years or more. However, factors such as usage intensity and environmental conditions can affect their lifespan.

Can metal sheet PU sandwich panels be used for both walls and ceilings in cold rooms?

Yes, these panels are versatile and can be used for both walls and ceilings in cold room construction, providing consistent insulation throughout the facility.

References

1.International Association of Cold Storage Construction. (2022). Cold Storage Design and Construction Guidelines.

2.Journal of Cold Chain Management. (2021). Advancements in Insulation Materials for Cold Storage Facilities.

3.European Food Safety Authority. (2023). Guidelines for Food Safety in Cold Storage Environments.

4.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2022). ASHRAE Handbook - Refrigeration.

5.International Building Code. (2021). Chapter 26: Plastic.