Grasping Prefabricated Thermal Panels

Composition and Structure of Prefabricated Thermal Panels

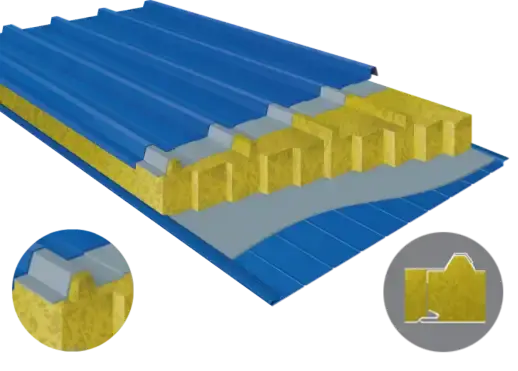

Prefabricated thermal panels are engineered building components designed to provide superior insulation and structural support. These panels typically consist of three main layers: an outer facing, an insulation core, and an inner facing. The outer and inner facings are usually made from durable materials such as aluminum, steel, or stainless steel, while the core is filled with high-performance insulation materials like polyurethane, polystyrene, rock wool, or glass wool.

The unique composition of prefabricated thermal panels allows for excellent thermal resistance and energy efficiency. The insulation core acts as a barrier against heat transfer, helping to maintain comfortable indoor temperatures year-round. Meanwhile, the metal facings provide strength, durability, and weather resistance, protecting the insulation and contributing to the overall structural integrity of the building.

Types of Prefabricated Thermal Panels

Prefabricated thermal panels come in various types, each designed to meet specific building requirements and applications. Some common types include:

- Sandwich panels: These panels feature two metal skins with an insulating core sandwiched between them, offering excellent thermal performance and structural strength.

- Insulated metal panels (IMPs): Similar to sandwich panels, IMPs are specifically designed for exterior wall and roof applications, providing both insulation and weather protection.

- Structural insulated panels (SIPs): These panels combine structural sheathing with an insulating foam core, often used in residential and light commercial construction.

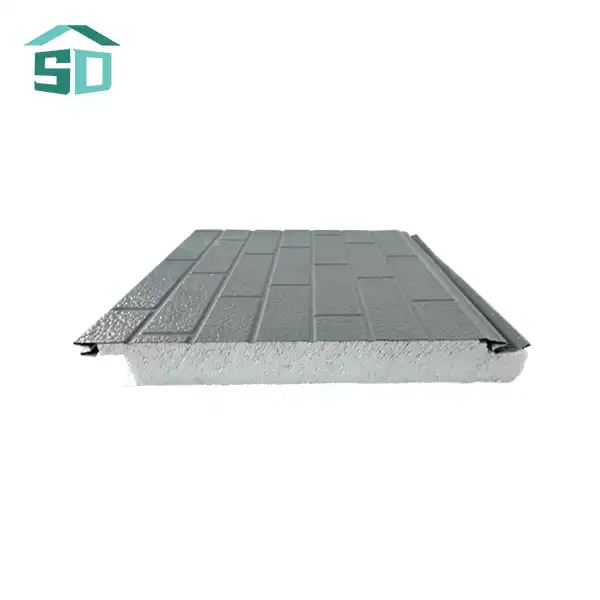

- Architectural panels: These panels are designed with aesthetics in mind, offering a range of finishes and textures for decorative purposes while maintaining thermal efficiency.

Benefits of Using Prefabricated Thermal Panels

Prefabricated thermal panels offer numerous benefits that make them an attractive option for modern construction projects:

- Energy efficiency: The high insulation value of these panels significantly reduces heat transfer, leading to lower energy consumption and costs.

- Quick installation: Their modular design allows for rapid assembly on-site, reducing construction time and labor costs.

- Versatility: Prefabricated thermal panels can be used in various applications, from exterior walls and roofs to interior partitions.

- Durability: The robust construction of these panels ensures long-lasting performance and resistance to weather elements.

- Customization: Panels can be tailored to specific project requirements, including size, thickness, and finish options.

- Sound insulation: Many prefabricated thermal panels offer excellent acoustic properties, enhancing indoor comfort.

- Fire resistance: Depending on the materials used, these panels can provide enhanced fire safety features.

Applications of Prefabricated Thermal Panels in Construction

Residential Construction

In the residential sector, prefabricated thermal panels have become increasingly popular for their energy-efficient properties and ease of installation. These panels are commonly used in the construction of single-family homes, multi-unit dwellings, and modular houses. The application of prefabricated thermal panels in residential buildings offers several advantages:

- Improved energy efficiency: The high insulation value of these panels helps maintain comfortable indoor temperatures, reducing heating and cooling costs.

- Faster construction: The prefabricated nature of these panels allows for quicker assembly on-site, reducing overall construction time.

- Design flexibility: Prefabricated thermal panels can be customized to fit various architectural styles and designs, offering homeowners more options.

- Durability: These panels provide excellent resistance to weather elements, ensuring long-lasting performance and reduced maintenance needs.

- Sound insulation: The insulating properties of prefabricated thermal panels also contribute to improved acoustic comfort in residential spaces.

Commercial and Industrial Applications

The use of prefabricated thermal panels extends beyond residential construction, finding extensive applications in commercial and industrial buildings. These panels are particularly well-suited for large-scale projects such as:

- Warehouses and distribution centers

- Manufacturing facilities

- Cold storage units

- Office buildings

- Retail spaces

- Educational institutions

- Healthcare facilities

In these applications, prefabricated thermal panels offer numerous benefits:

- Energy efficiency: The superior insulation properties help maintain consistent temperatures in large spaces, reducing energy consumption.

- Rapid construction: The modular nature of these panels allows for faster project completion, minimizing downtime for businesses.

- Structural integrity: Prefabricated thermal panels provide excellent load-bearing capacity, making them suitable for large-scale structures.

- Hygiene and cleanliness: In facilities requiring strict hygiene standards, such as food processing plants or healthcare facilities, these panels offer smooth, easy-to-clean surfaces.

- Fire resistance: Many prefabricated thermal panels are designed with fire-resistant properties, enhancing overall building safety.

The versatility of prefabricated thermal panels makes them an ideal choice for a wide range of commercial and industrial applications, offering both functional and economic advantages.

Specialized Applications

Beyond standard construction, prefabricated thermal panels find use in several specialized applications:

- Cold rooms and freezers: The excellent insulation properties make these panels ideal for maintaining low temperatures in food storage facilities.

- Clean rooms: In industries requiring controlled environments, such as pharmaceuticals or electronics manufacturing, prefabricated thermal panels help maintain precise temperature and humidity levels.

- Data centers: These panels assist in creating energy-efficient and temperature-controlled environments for sensitive electronic equipment.

- Agricultural buildings: Prefabricated thermal panels are used in the construction of barns, greenhouses, and other agricultural structures to maintain optimal growing conditions.

- Modular and portable buildings: The lightweight and easy-to-assemble nature of these panels makes them perfect for temporary or relocatable structures.

Choosing the Right Prefabricated Thermal Panels

Factors to Consider When Selecting Prefabricated Thermal Panels

When choosing prefabricated thermal panels for a construction project, several key factors should be taken into account:

- Insulation value: Consider the R-value or U-value of the panels, which indicates their thermal resistance. Higher values mean better insulation performance.

- Panel thickness: The thickness of the panel affects both its insulation properties and its structural capabilities. Choose a thickness that balances thermal performance with space constraints.

- Core material: Different insulation materials offer varying levels of thermal performance, fire resistance, and acoustic properties. Common options include polyurethane, polystyrene, rock wool, and glass wool.

- Facing material: The outer and inner facings of the panel contribute to its durability and aesthetic appeal. Options may include aluminum, steel, or stainless steel, each with its own advantages.

- Fire resistance: Ensure the chosen panels meet local fire safety regulations and provide adequate protection for the building's intended use.

- Weather resistance: Consider the panel's ability to withstand local climate conditions, including UV radiation, moisture, and temperature fluctuations.

- Acoustic performance: If sound insulation is a priority, look for panels with high sound transmission class (STC) ratings.

- Aesthetics: Choose panels that align with the desired architectural style and finish of the building.

- Installation requirements: Consider the ease of installation and any specialized tools or skills required for proper assembly.

- Cost: Balance the initial cost of the panels with their long-term energy savings and maintenance requirements.

Performance Standards and Certifications

When selecting prefabricated thermal panels, it's crucial to consider relevant performance standards and certifications. These ensure that the panels meet industry requirements for quality, safety, and performance. Some important standards and certifications to look for include:

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials

- NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components

- ISO 9001: Quality Management System certification

- LEED certification: For panels contributing to sustainable building practices

- Energy Star certification: Indicating energy efficiency

- FM Approvals: Testing for severe weather conditions and fire resistance

- UL Listings: Certifying product safety and performance

Working with Prefabricated Thermal Panels Suppliers

Collaborating with reputable prefabricated thermal panels suppliers is essential for successful project implementation. When working with suppliers, consider the following aspects:

- Product range: Choose a supplier offering a diverse range of panel types, thicknesses, and finishes to meet various project requirements.

- Technical support: Look for suppliers providing comprehensive technical assistance, from design consultation to installation guidance.

- Customization options: Seek suppliers capable of tailoring panels to specific project needs, including custom sizes, colors, and finishes.

- Quality control: Ensure the supplier maintains strict quality control measures throughout the manufacturing process.

- Delivery and logistics: Consider the supplier's ability to meet project timelines and handle logistics efficiently.

- Warranty and after-sales support: Evaluate the warranty terms and the level of post-installation support offered by the supplier.

- Sustainability practices: If environmental considerations are important, look for suppliers committed to sustainable manufacturing processes and recyclable materials.

Conclusion

Prefabricated thermal panels have emerged as a game-changing solution in modern construction, offering a perfect blend of energy efficiency, structural integrity, and design flexibility. From residential homes to large-scale industrial facilities, these versatile panels provide superior insulation, rapid installation, and long-lasting performance. By carefully considering factors such as insulation values, material composition, and relevant certifications, builders and architects can select the ideal prefabricated thermal panels for their specific project needs. As the construction industry continues to prioritize sustainability and efficiency, prefabricated thermal panels are poised to play an increasingly vital role in shaping the buildings of tomorrow.

Are you ready to experience the benefits of prefabricated thermal panels in your next construction project? At Weifang Sandong Building Materials Co., Ltd., we offer a wide range of high-quality, customizable prefabricated thermal panels designed to meet your specific needs. Our expert team is ready to assist you in selecting the perfect panels for your project, ensuring optimal energy efficiency, durability, and aesthetic appeal. Contact us today at info@sdqsc.com to learn more about our innovative solutions and how we can help bring your construction vision to life.

FAQs

What are the main advantages of using prefabricated thermal panels?

Prefabricated thermal panels offer excellent energy efficiency, quick installation, versatility in applications, durability, customization options, sound insulation, and potential fire resistance.

How do prefabricated thermal panels contribute to energy savings?

These panels provide superior insulation, reducing heat transfer and maintaining consistent indoor temperatures, which leads to lower energy consumption for heating and cooling.

Can prefabricated thermal panels be used in both new construction and renovation projects?

Yes, these panels are suitable for both new builds and renovations, offering flexibility in various construction scenarios.

What types of buildings can benefit from prefabricated thermal panels?

A wide range of structures can benefit, including residential homes, commercial buildings, industrial facilities, cold storage units, and specialized environments like clean rooms and data centers.

How do I choose the right prefabricated thermal panels for my project?

Consider factors such as insulation value, panel thickness, core and facing materials, fire resistance, weather resistance, acoustic performance, aesthetics, installation requirements, and cost. Consult with experienced suppliers for guidance.

References

1. American Society for Testing and Materials. (2021). ASTM E84-21a: Standard Test Method for Surface Burning Characteristics of Building Materials. ASTM International.

2. National Fire Protection Association. (2019). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components. NFPA.

3. International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements. ISO.

4. U.S. Green Building Council. (2021). LEED v4.1 Building Design and Construction. USGBC.

5. ENERGY STAR. (2021). ENERGY STAR Certification for Building Materials. U.S. Environmental Protection Agency.